Furnace slag granulation equipment for vanadium-titanium magnetite blast furnace

A technology of granulation equipment and vanadium-titanium magnets, applied in recycling technology and other directions, can solve the problem of unsatisfactory fusion of high-pressure water flow and high-pressure air flow, and achieve the effect of improving the atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

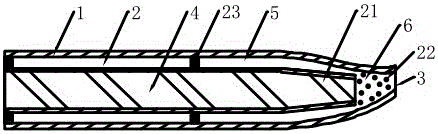

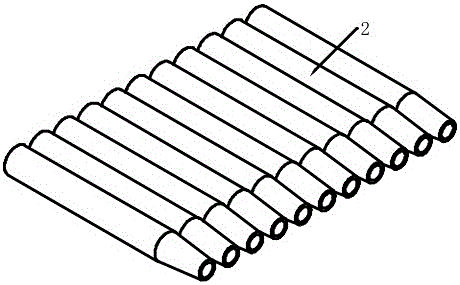

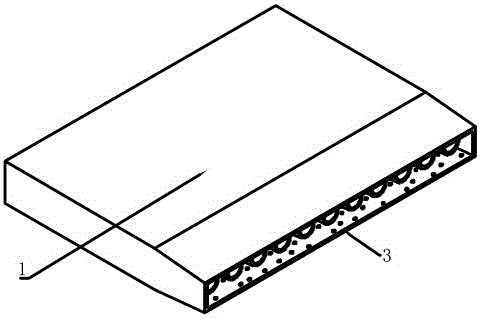

[0034] Such as Figure 1 to Figure 10 As shown, the slag granulation equipment of a vanadium-titanium magnet blast furnace in this embodiment includes an outer box body 1 with a flat spout 3 at the front end and a plurality of high-pressure water guide pipes installed horizontally and side by side in the outer box body 1 2. The inner wall of the high-pressure water diversion pipe 2 is provided with a spiral diversion groove 21, and the inner wall of the high-pressure water diversion pipe 2 forms a high-pressure water diversion chamber 4 for high-pressure water flow to pass through, and the high-pressure water diversion chamber 4 is connected with the external high-pressure Water source connection; the inner wall of the outer box 1 and the outer wall of the high-pressure water diversion pipe 2 form a high-pressure wind diversion cavity 5 for high-pressure gas to pass through, and the high-pressure wind diversion cavity 5 is connected to an external high-pressure gas source; the ...

Embodiment 2

[0038] In this embodiment, a slag granulation device for a vanadium-titanium magnet blast furnace includes an outer box body 1 with a flat jet outlet 3 arranged at the front end and a plurality of high-pressure water guide pipes 2 installed horizontally and side by side in the outer box body 1; The inner wall of the high-pressure water diversion pipe 2 is provided with a spiral diversion groove 21, and the inner wall of the high-pressure water diversion pipe 2 forms a high-pressure water diversion chamber 4 for the high-pressure water flow to pass through, and the high-pressure water diversion chamber 4 is connected to an external high-pressure water source; The inner wall of the outer box 1 and the outer wall of the high-pressure water diversion pipe 2 form a high-pressure wind diversion cavity 5 for high-pressure gas to pass through, and the high-pressure wind diversion cavity 5 is connected to an external high-pressure gas source; the high-pressure water diversion The front ...

Embodiment 3

[0043] In this embodiment, a slag granulation device for a vanadium-titanium magnet blast furnace includes an outer box body 1 with a flat jet outlet 3 arranged at the front end and a plurality of high-pressure water guide pipes 2 installed horizontally and side by side in the outer box body 1; The inner wall of the high-pressure water diversion pipe 2 is provided with a spiral diversion groove 21, and the inner wall of the high-pressure water diversion pipe 2 forms a high-pressure water diversion chamber 4 for the high-pressure water flow to pass through, and the high-pressure water diversion chamber 4 is connected to an external high-pressure water source; The inner wall of the outer box 1 and the outer wall of the high-pressure water diversion pipe 2 form a high-pressure wind diversion cavity 5 for high-pressure gas to pass through, and the high-pressure wind diversion cavity 5 is connected to an external high-pressure gas source; the high-pressure water diversion The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com