Continuous wall I-steel joint with water-swellable water-stopping strips

A water-swelling, I-beam technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of increasing water seepage paths, high cost, and large amount of steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

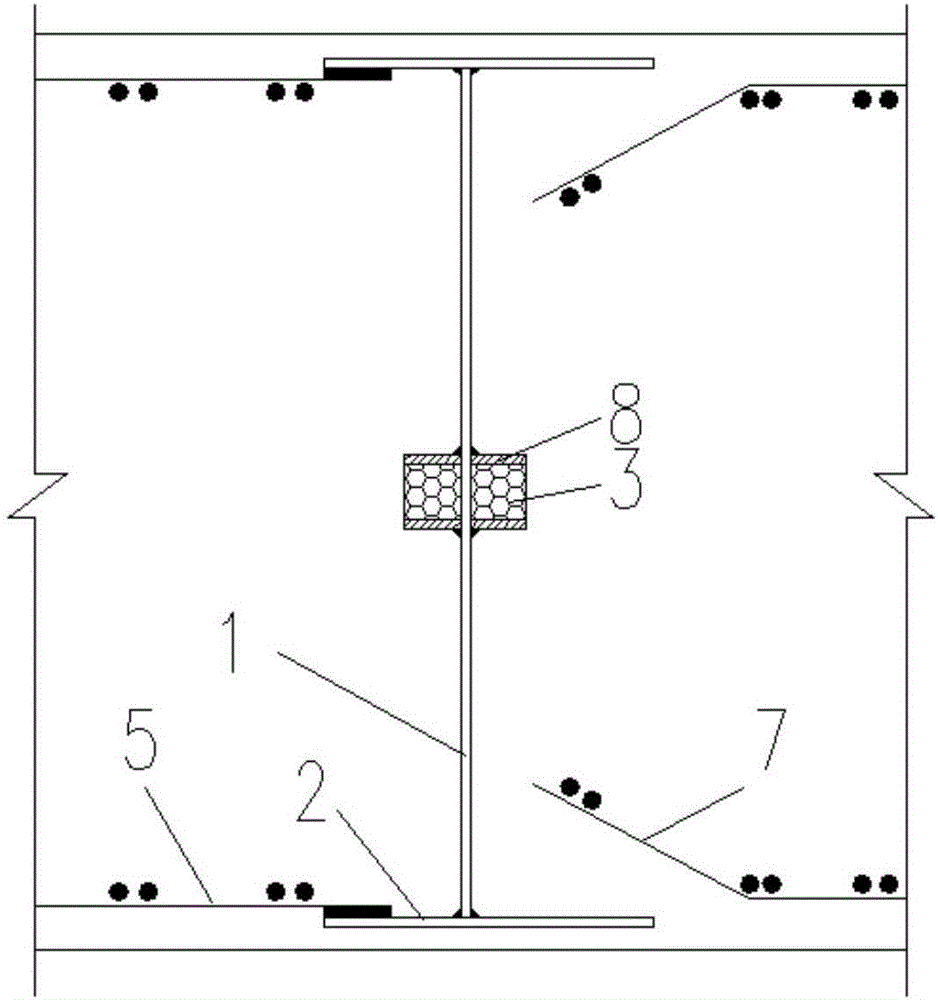

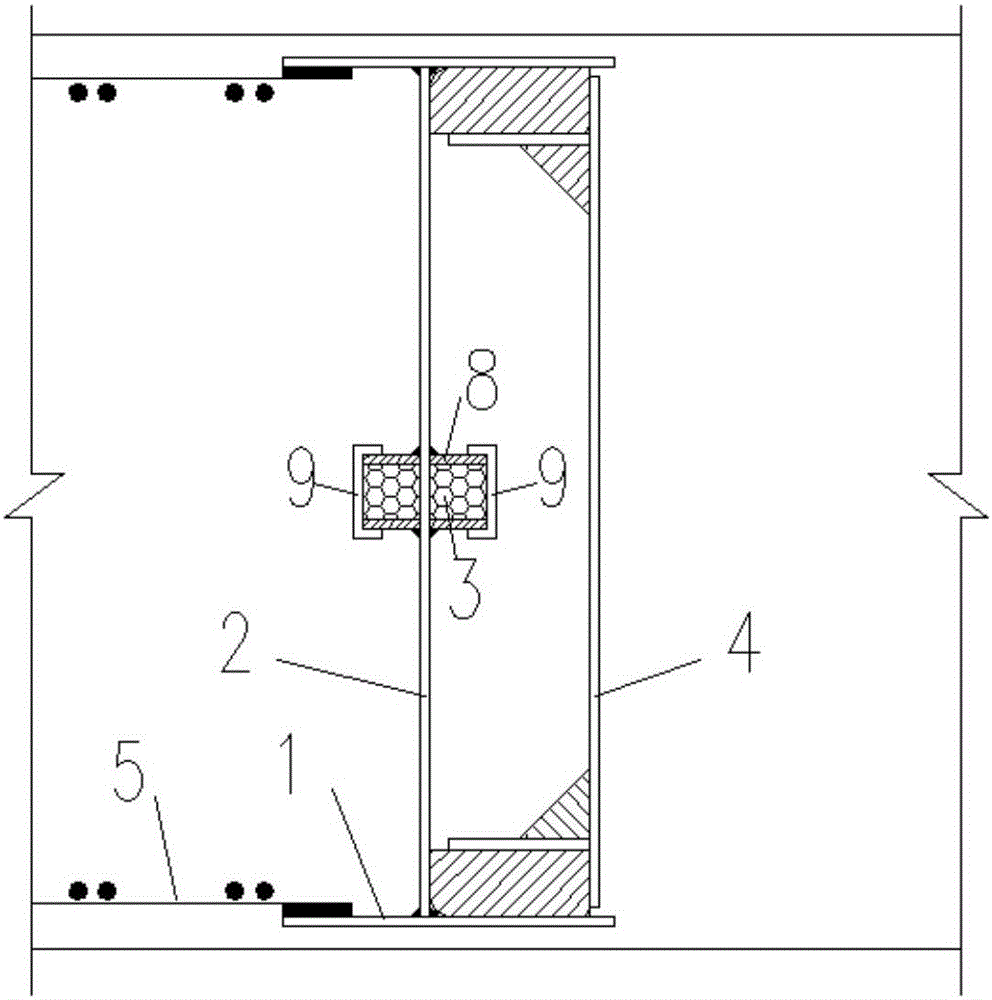

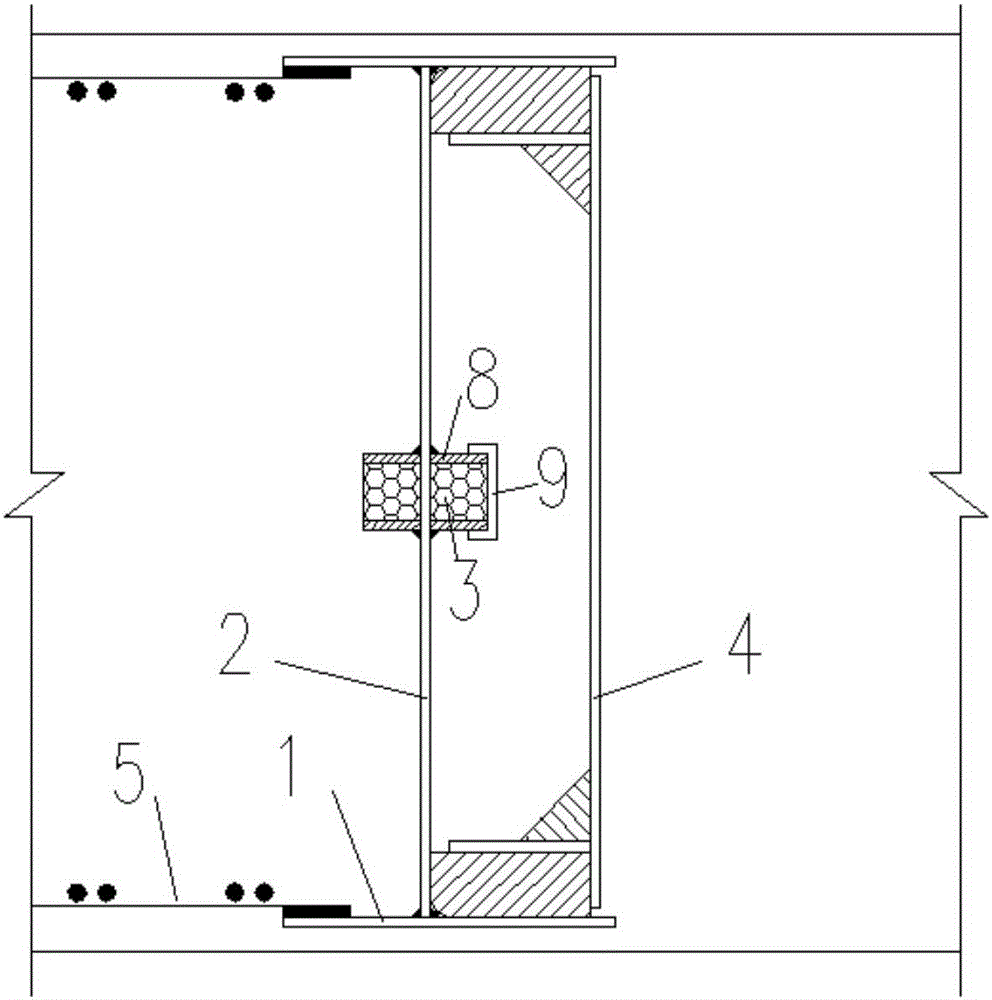

[0052] The site geology of a subway station consists of plain fill, silt, silt and medium sand from top to bottom. The water level of the site is relatively high, and there are multi-storey buildings near the foundation pit. more sensitive. After comparative analysis, the foundation pit enclosure structure adopts underground diaphragm wall + multi-channel internal support, the thickness of diaphragm wall is 1000mm, the vertical length of diaphragm wall is 40m, and the width of diaphragm wall section in standard section is 6m. Diaphragm wall I-beam joints for water-swellable waterstops.

[0053] Diaphragm wall is divided into according to the sequence of construction: first-stage continuous wall section, second-stage continuous wall section, first-stage continuous wall section, second-stage continuous wall section..., the first-stage continuous wall section is constructed first, and the concrete strength of the first-stage continuous wall section is waited After the design str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com