Gas-fired boiler denitration energy saver utilizing latent heat of water film droplet condensing steam

A gas-fired boiler and economizer technology, applied in feed water heaters, steam generation, preheating, etc., can solve the problems of losing money for environmental protection, failure to realize local utilization, and insufficient energy saving, and achieve the effect of increasing energy saving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

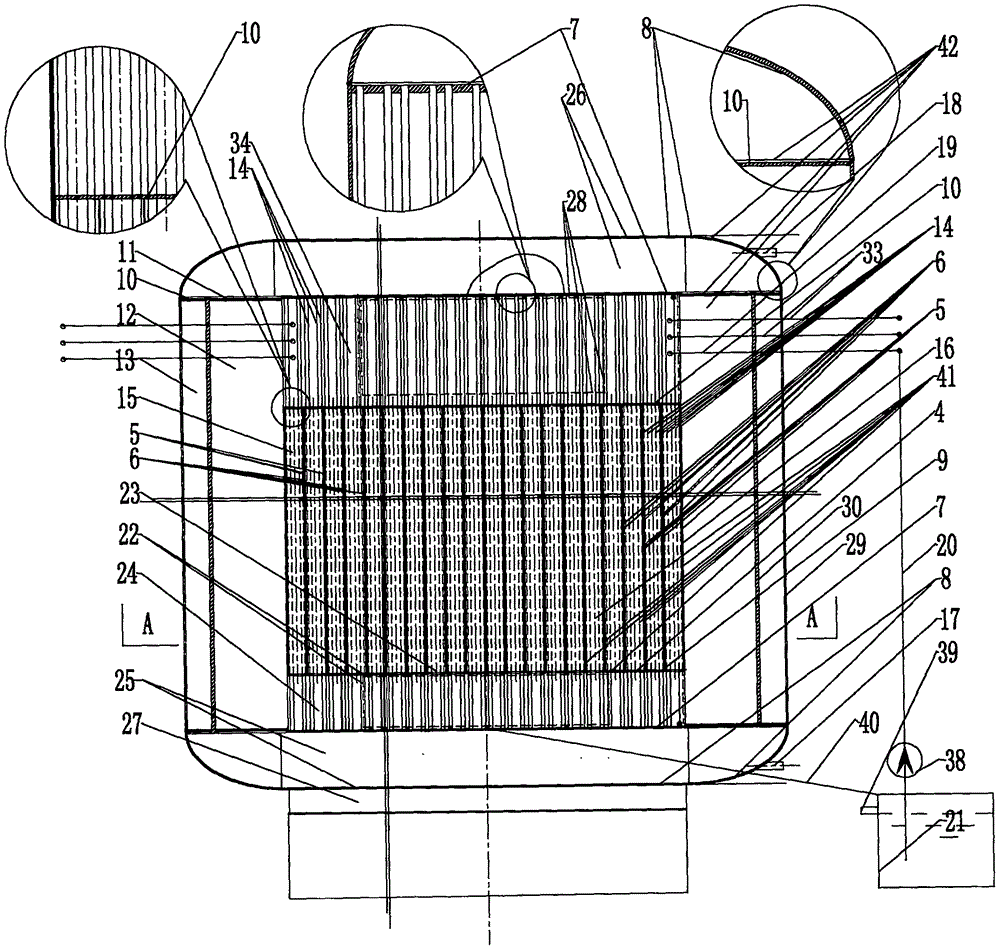

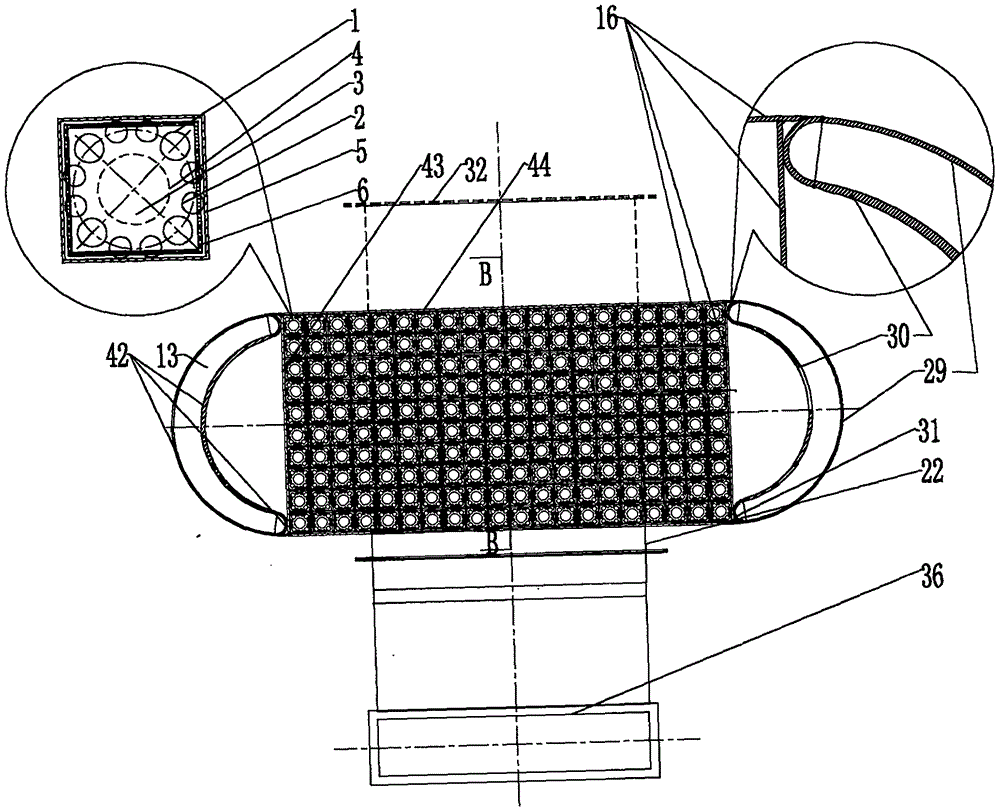

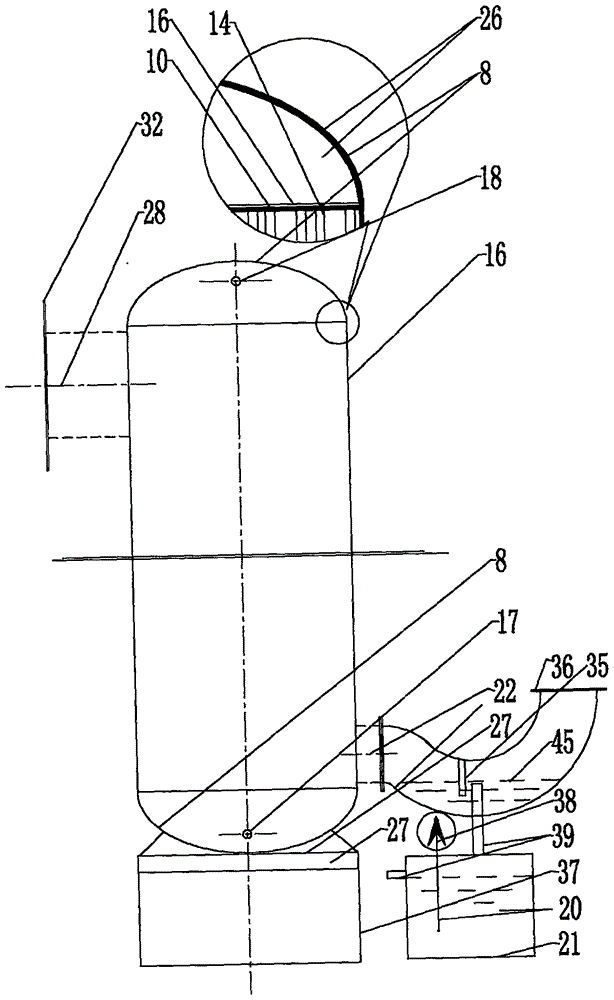

[0017] exist figure 1 Among them, the longitudinal cross-section of the four-sided streamline ellipse and the four-sided round vertical cuboid is assembled with two hundred to several square smoke pipes 5 (every pipe 5 is lined with stainless steel gauze 6). The smoke distribution center 41 of the 5th branch smoke chamber 3 basic units is formed into an array. The center 41 is assembled and assembled into the middle part of the vertical non-pressure-bearing flue package sleeve 16, and each corresponding to the inside of the smoke distribution pipe is equipped with a Four tube bundles 14 for boiler feedwater distribution, the tube bundle 14 is provided with a support plate 9 at the bottom of the smoke distribution center 41 (there are four pipe holes 1 and eight smoke distribution outlets 2 on the plate 9), the tube bundle 14 Excessive smoke distribution water plate 10 passes upward into upper header 26 and is welded or expanded with its bottom tube plate 7 of header 26, tube b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap