Center powder feeding swirling pulverized coal combustion device preventing slag forming of water cooling wall

A technology of pulverized coal combustion and water-cooled wall, applied in the burner, combustion method, combustion type, etc., can solve the problems of high NOx emission and serious slagging, and achieves reduction of NOx emission, improvement of conversion rate, and avoidance of in-furnace formation. slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

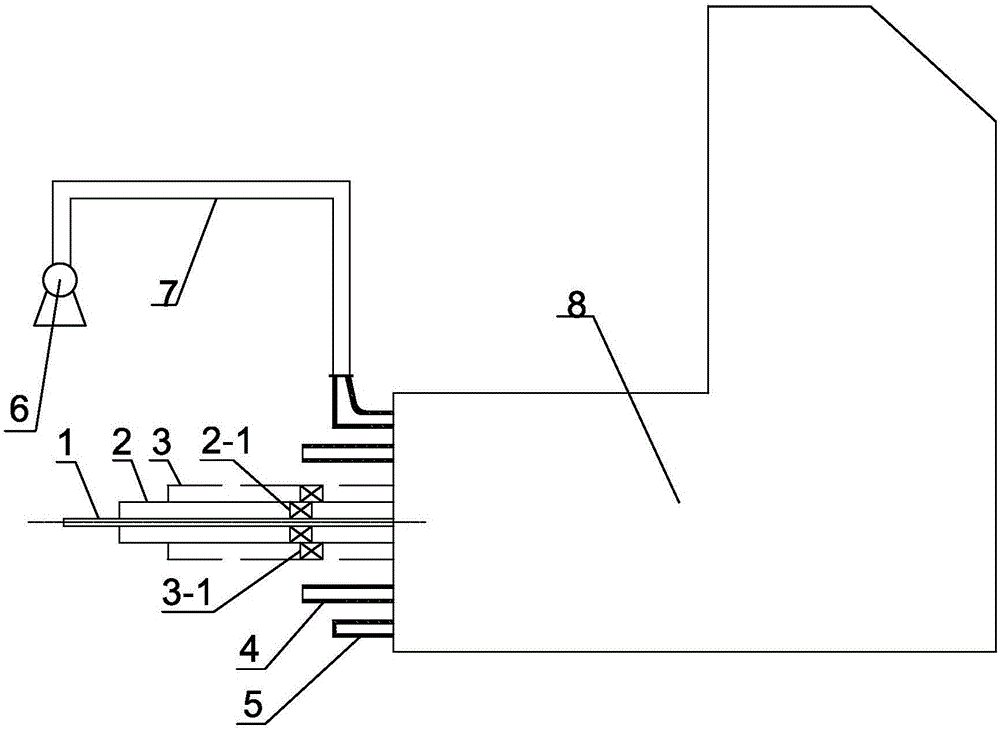

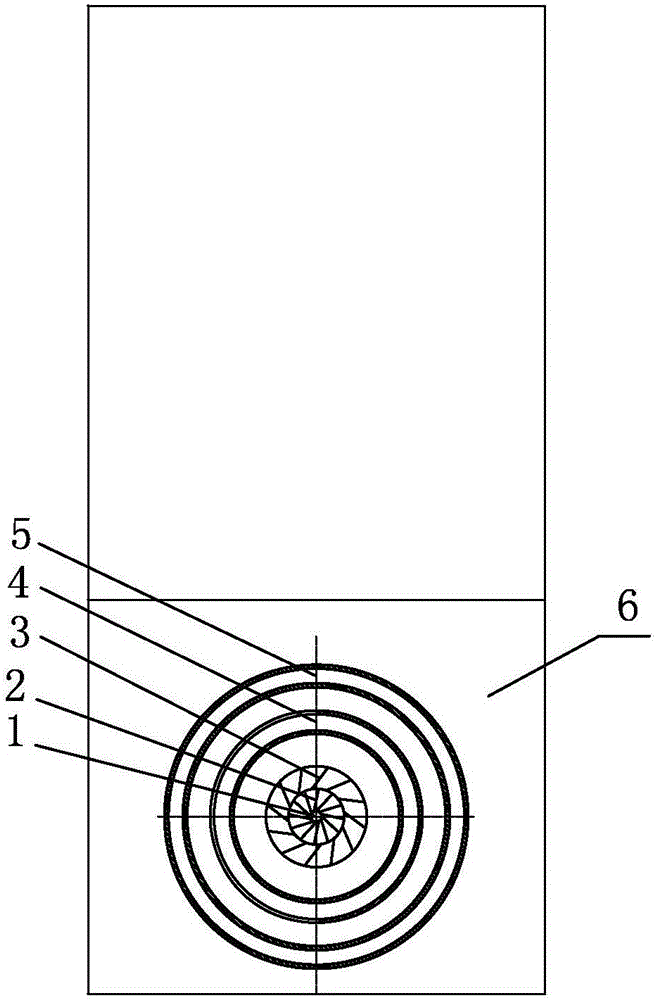

[0026] Specific implementation mode one: see figure 1 and figure 2 To illustrate, a center-feeding swirl pulverized coal combustion device for preventing water wall slagging in this embodiment includes a primary air duct 1, an inner secondary air channel 2, an outer secondary air channel 3, and an inner secondary air cyclone 2-1, external secondary air cyclone 3-1, annular overburning air channel 4, annular recirculation flue gas channel 5, induced draft fan 6 and recirculation flue gas pipe 7, one end of the induced draft fan 6 is connected to the tail of the boiler The flue gas channel is connected, the other end is connected to the inlet end of the recirculation flue gas pipe 7, the outlet end of the recirculation flue gas pipe 7 is connected to the annular recirculation flue gas channel 5, and the primary air pipe 1 is set inside the secondary In the air channel 2, the inner secondary air channel 2 is set in the outer secondary air channel 3, the inner secondary air cycl...

specific Embodiment approach 2

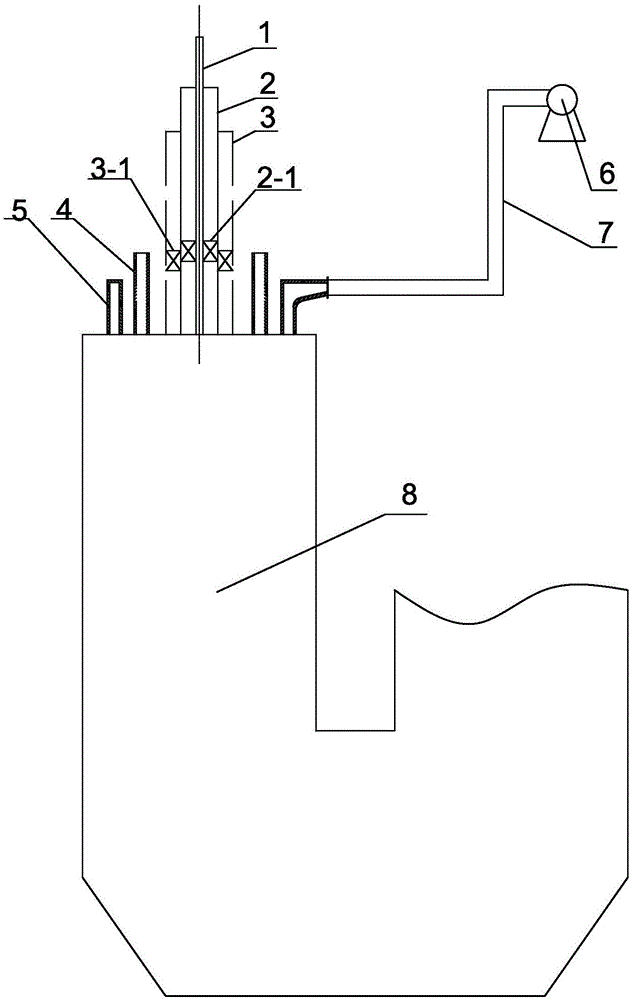

[0028] Specific implementation mode two: combination image 3 Note that the nozzles of the primary air pipe 1 , the inner secondary air passage 2 and the outer secondary air passage 3 of this embodiment are arranged on the furnace roof of the pulverized coal vertical boiler. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 4 and Figure 5 It is explained that a center-feeding swirl flow pulverized coal combustion device for preventing water wall slagging in this embodiment also includes an overburning wind swirling blade 4-1, and the overburning wind swirling blade 4-1 is arranged on the annular combustion chamber. In the exhaust channel 4. This structure can strengthen the mixing of the overburning air and the high-temperature flue gas in the main combustion zone, which is beneficial to the continuous burning of unburned coal particles in the high-temperature flue gas. In this embodiment, the overfired air is in the form of swirling flow, and the recirculated flue gas is in the form of direct flow. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com