Heat accumulating type flue gas recirculation combustion nozzle and combustion system

A flue gas recirculation, regenerative technology, applied in the combustion chamber, combustion method, combustion type, etc., can solve the problem of single combustion method, large amount of pollutants such as NOx, difficult to meet environmental protection standards, and low energy utilization rate of burners and other problems, to achieve the effect of reducing combustion temperature, reducing concentration, and reducing NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

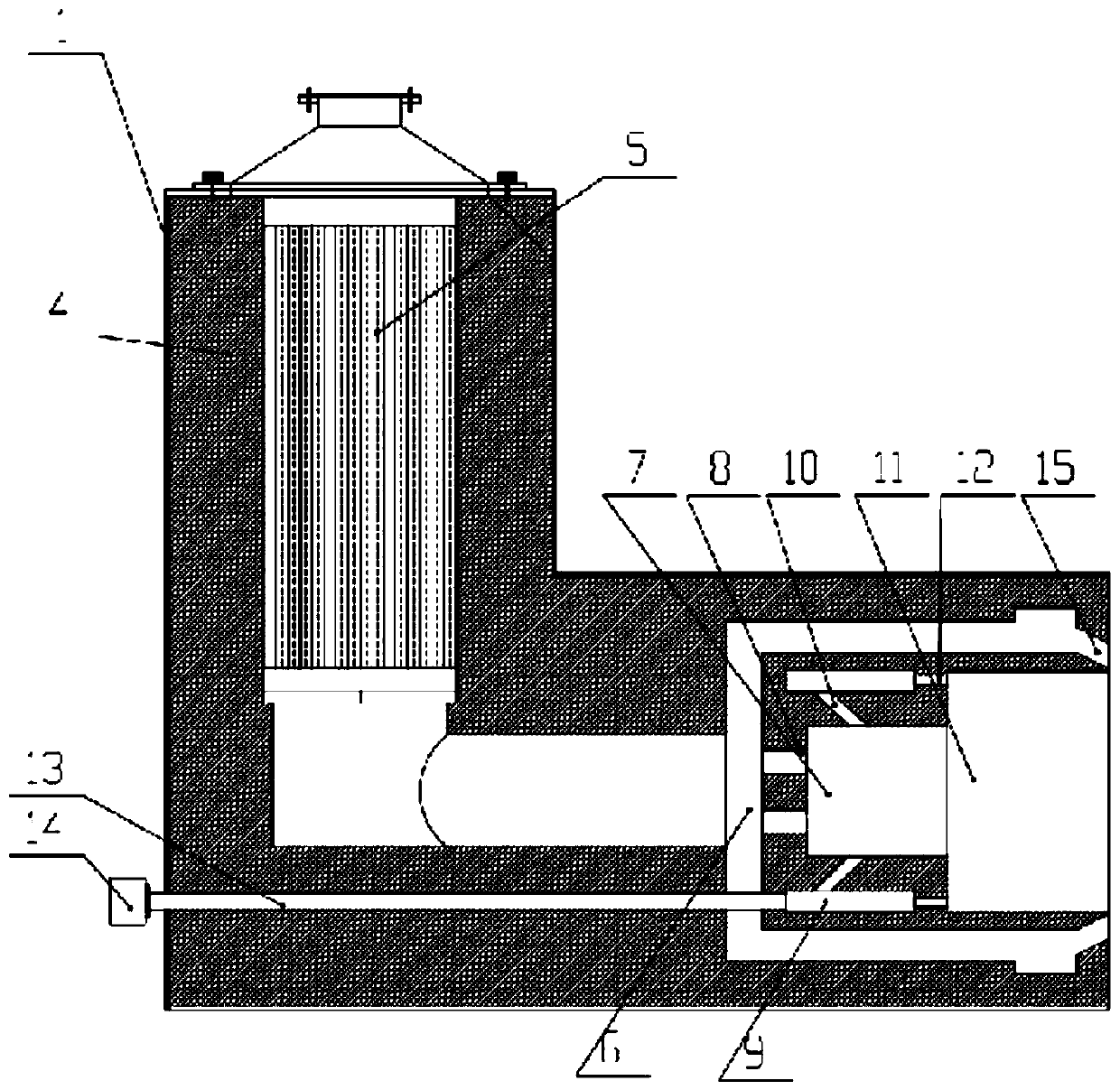

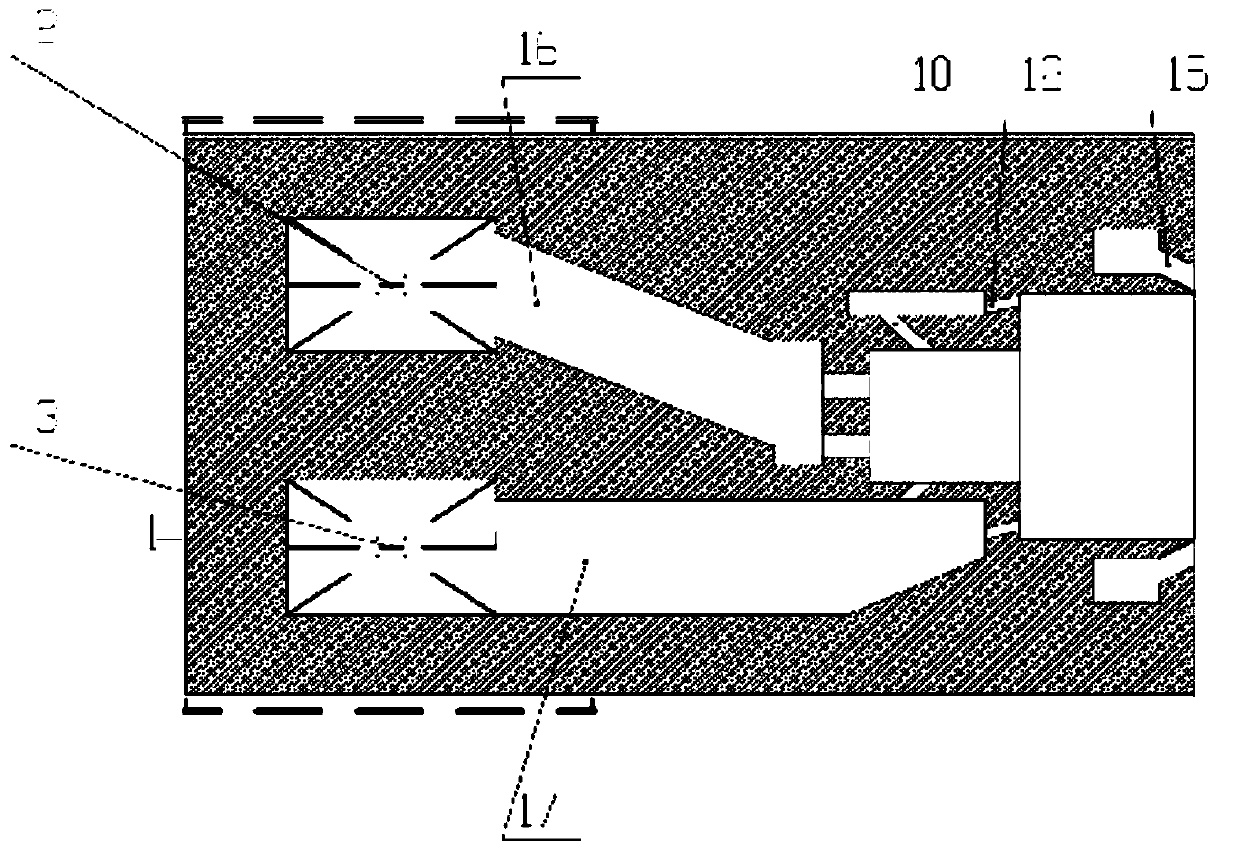

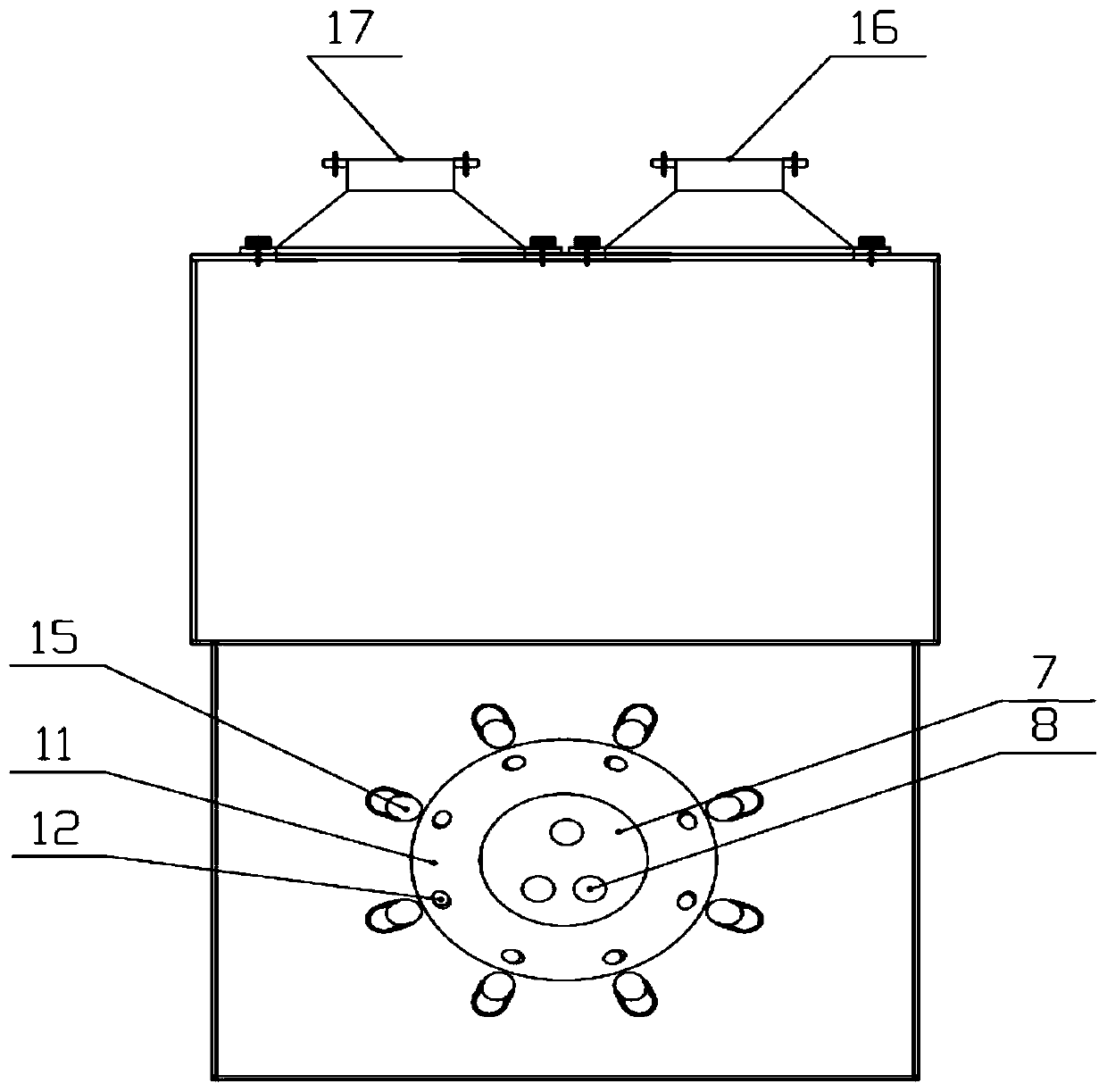

[0035] see Figure 1-Figure 3 , a regenerative flue gas recirculation burner in this embodiment, including a gas heat storage box 2, an air heat storage box 3, a primary combustion chamber 7 and a secondary combustion chamber 11, after the gas passes through the gas heat storage box 2 It flows through the gas channel 16 and enters the gas classification channel 6, the air passes through the air heat storage tank 3 and then flows through the air flue gas channel 17 and enters the air classification channel 9, and the gas and air enter the first level, In the secondary combustion chamber and the hearth of the industrial furnace; the air classification channel 9 is connected with a flue gas recirculation channel 13, which is used to further pass the flue gas generated after combustion into the burner for combustion, and finally achieve the purpose of multi-stage combustion.

[0036] The gas classification passage 6 communicates with the primary combustion chamber 7 through the pr...

Embodiment 2

[0043] The structure in this embodiment is basically the same as that of Embodiment 1, except that the acute angle between the swirl air hole and the tangential direction of the circle is 60°, the acute angle between the secondary gas hole and the horizontal direction is 45°, and the swirl flow The gas hole and the secondary gas hole are square column holes, and a plurality of heat storage balls are arranged in the heat storage box.

[0044] According to the design idea of the present invention, in addition to the above-mentioned structure, the inclination angle of the swirl air hole and the secondary gas hole can also be adjusted according to the actual situation; the heat storage box can also be composed of a plurality of honeycomb heat storage bodies and heat storage balls; in addition , the number of primary gas holes, combustion-supporting air holes, swirl air holes and secondary gas holes can also be adjusted according to specific combustion conditions; the number of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com