Low-nitrogen combustion device for enhancing pulverized coal gasification

A technology of low-nitrogen combustion and pulverized coal, which is applied to the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, the combustion of liquid fuel and gaseous fuel, etc., which can solve the problem of weak reducibility, Low NOx removal rate and other issues, to achieve the effect of reducing NOx generation, obvious environmental benefits, and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

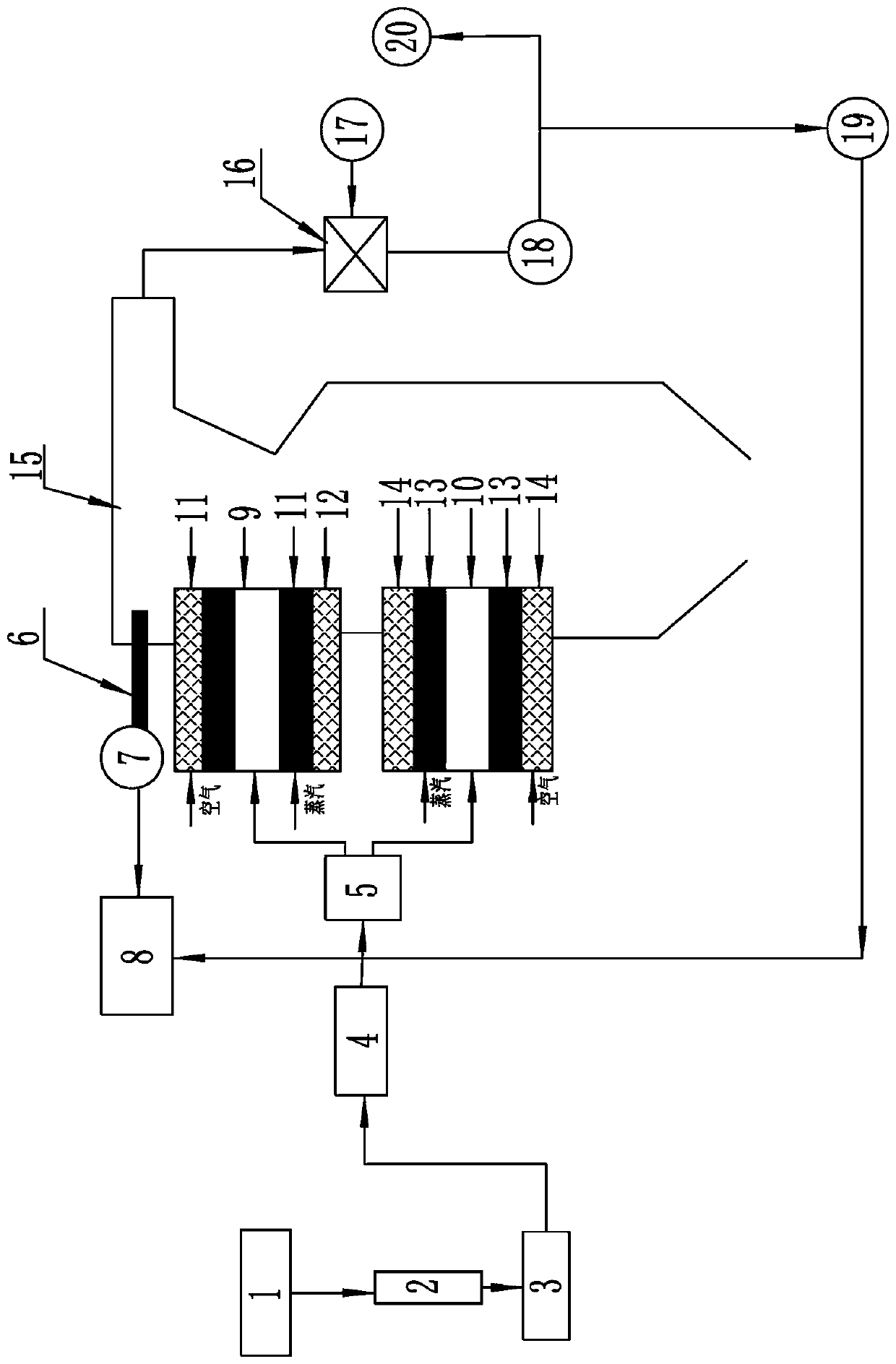

[0013] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached figure 1 The present invention will be further described in detail with specific embodiments.

[0014] It is characterized in that the discharge end of the descending drying pipe, the fan coal mill and the coarse powder separator are sequentially connected through pipelines.

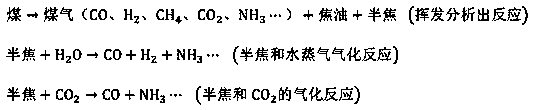

[0015] The low-nitrogen combustion device for strengthening pulverized coal gasification used in this embodiment includes a coal feeder 1, a descending drying pipe 2, a fan coal mill 3, a coarse powder separator 4, a thick and light powder separator 5, and a concentrated coal pulverized combustion device, light pulverized coal burner, furnace 15, high temperature resistant pipe 6, high temperature flue gas induced draft fan 7, gas mixing device 8, air preheater 16, blower 17, induced draft fan 18, chimney 20 and primary air channel for conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com