A protection device for a closed rolling force measuring sensor

A technology for measuring sensors and protection devices, applied in the directions of measuring devices, measuring forces, instruments, etc., can solve the problems of inaccurate measured values, affecting the normal production of rolling steel, and high damage rate of the indenter, achieving no maintenance, avoiding load distribution, and easy to use. The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

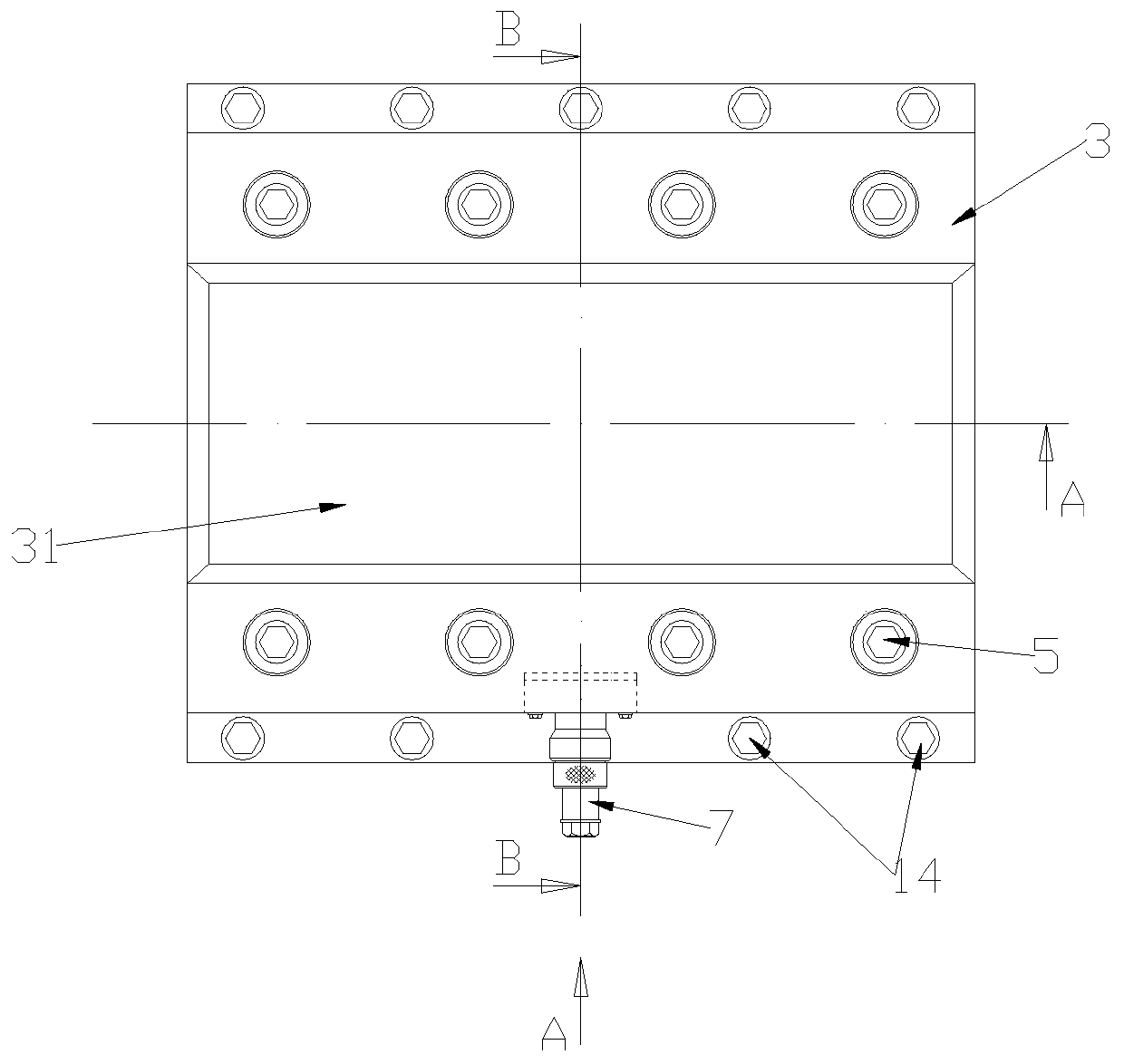

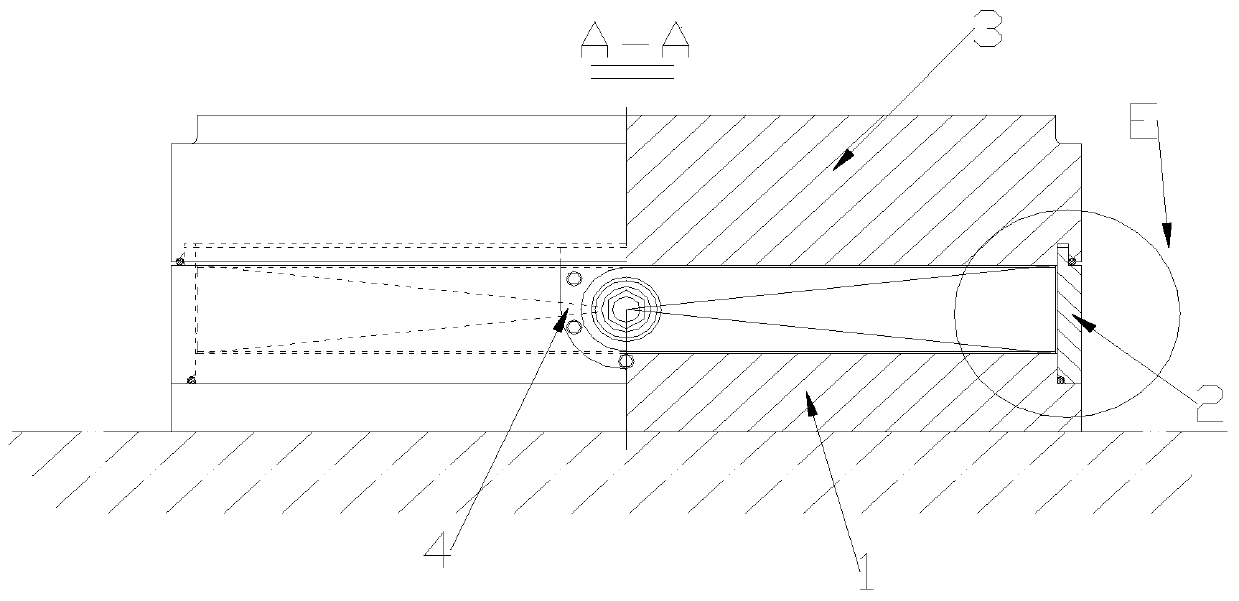

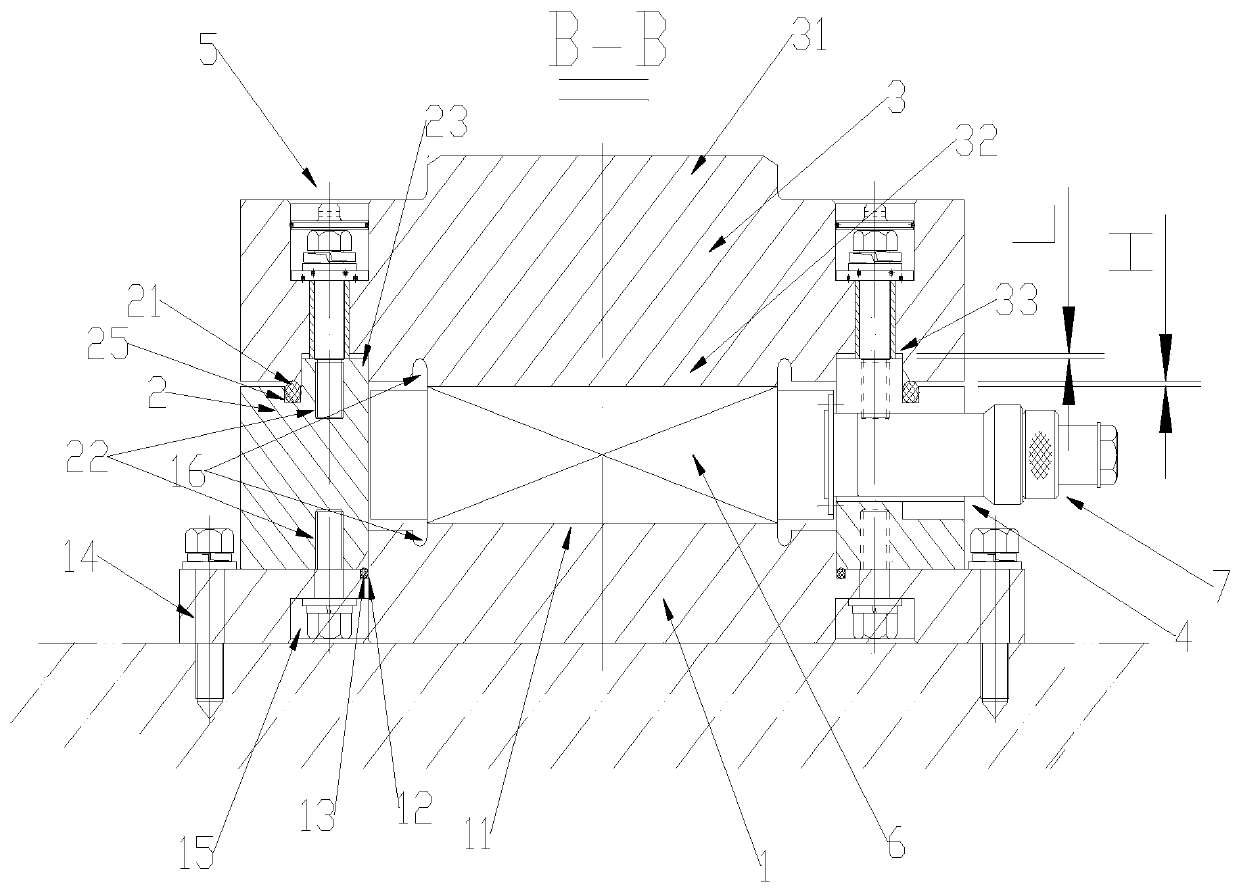

[0037] like figure 1 , 2 , 3, 4, and 5, the protective device of the closed rolling force measuring sensor includes an upper bearing plate 3, a lower bearing plate 1 and a surrounding frame 2, the surrounding frame 2 is a closed rectangular frame, and the surrounding frame 2 The inner edge of the upper end surface is provided with a ring of spigot boss 23, the cross section of spigot boss 23 is rectangular, and a circle of closed first groove 25 is arranged around the root of spigot boss 23, and the surrounding frame sealing ring 21 Installed in the first groove 25, the surrounding frame sealing ring 21 is used to seal the gap between the lower surface of the upper pressure bearing plate 3 and the upper end surface of the surrounding frame 2, so as to prevent dirt and water vapor 8 from entering the box to form a certain thickness of dirt , causing the indenter 6 to be partially overloaded due to poor load distribution and the indenter 6 to be damaged. The lower end surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com