Measurement apparatus of non-contact toothed disk frequency and method thereof

A non-contact, measuring device technology, applied in the direction of frequency measuring device, measuring device, frequency to pulse sequence conversion, etc., can solve the problem that the processing accuracy is difficult to ensure the hydroelectric generator set, affecting the real-time performance of frequency measurement, etc., to achieve Improve the reliability of power supply, improve fault tolerance, and suppress the effect of sudden interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

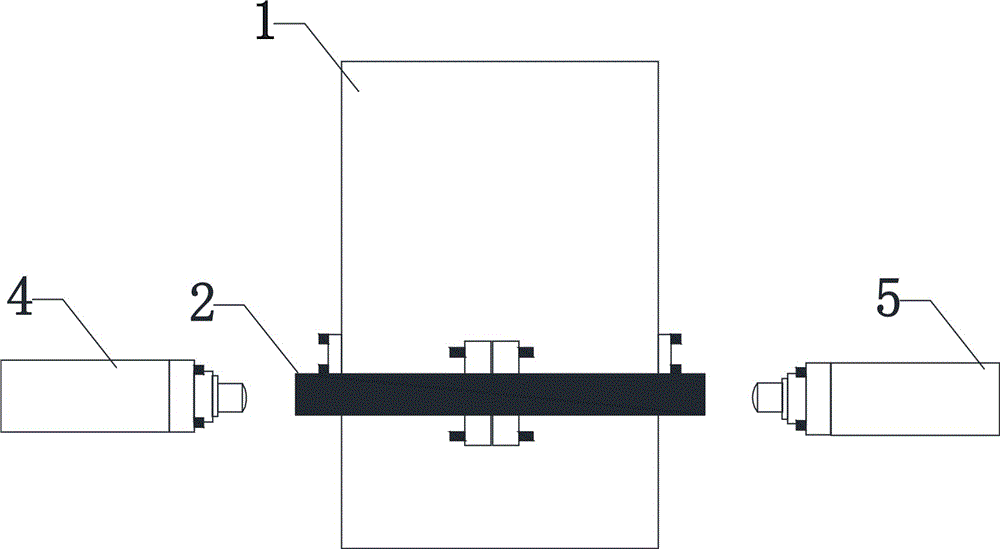

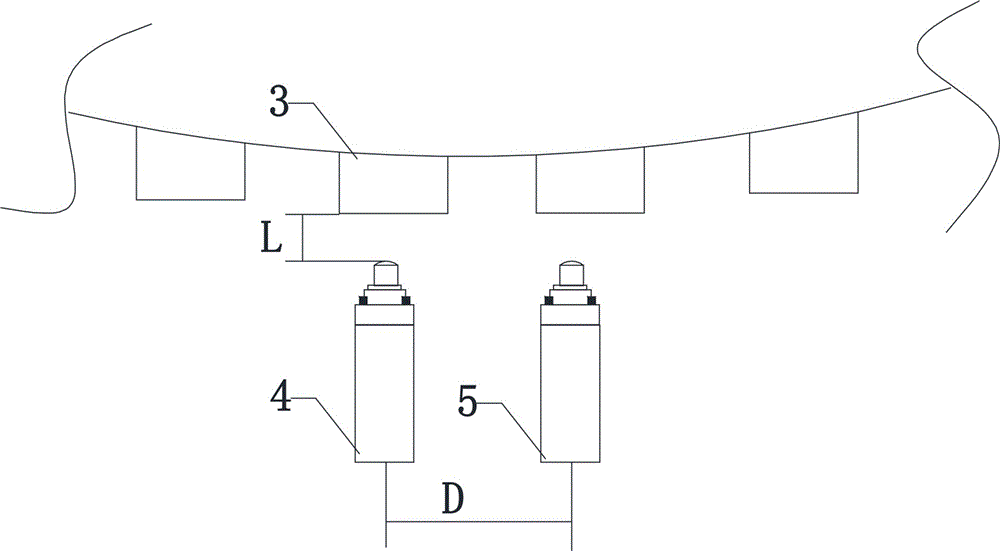

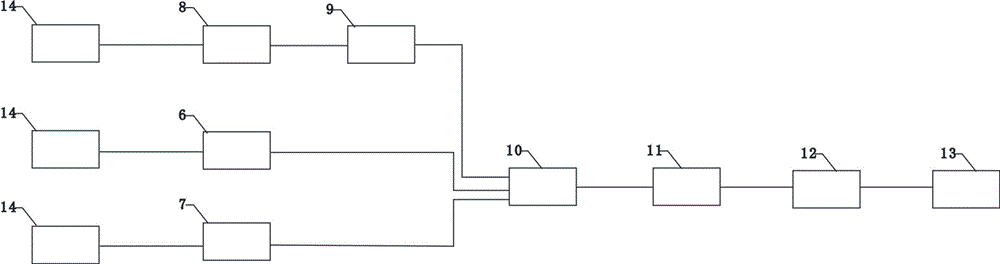

[0042] The invention provides a non-contact measuring device for the frequency of the toothed disk, which includes the main shaft 1 of the hydroelectric generator set, the 1# speed measuring probe 4, the 2# speed measuring probe 5, the toothed disk and the 1# speed measuring probe to form the frequency generator of the 1# toothed disk Unit 6, tooth plate and 2# speed measuring probe form 2# tooth plate frequency generating unit 7, residual voltage frequency signal 8, frequency signal isolation transformer 9, frequency signal conversion board 10, frequency measurement module 11, PLC controller 12, touch screen 13 , Redundant power supply module 14. Wherein by tooth belt 2 and tooth head 3 form a toothed disc.

[0043] The toothed plate is installed on the large shaft 1 of the hydro-generator in the waterwheel chamber section, and the gear head 3 is evenly installed on the toothed belt 2 in a certain order and quantity, and is connected with 1# speed measuring probe 4 and 2# spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com