Two-redundancy steering engine control system based on CAN bus

A CAN bus and control system technology, applied in the mechanical field, can solve problems such as force disputes, and achieve the effects of solving force disputes, high reliability and real-time performance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

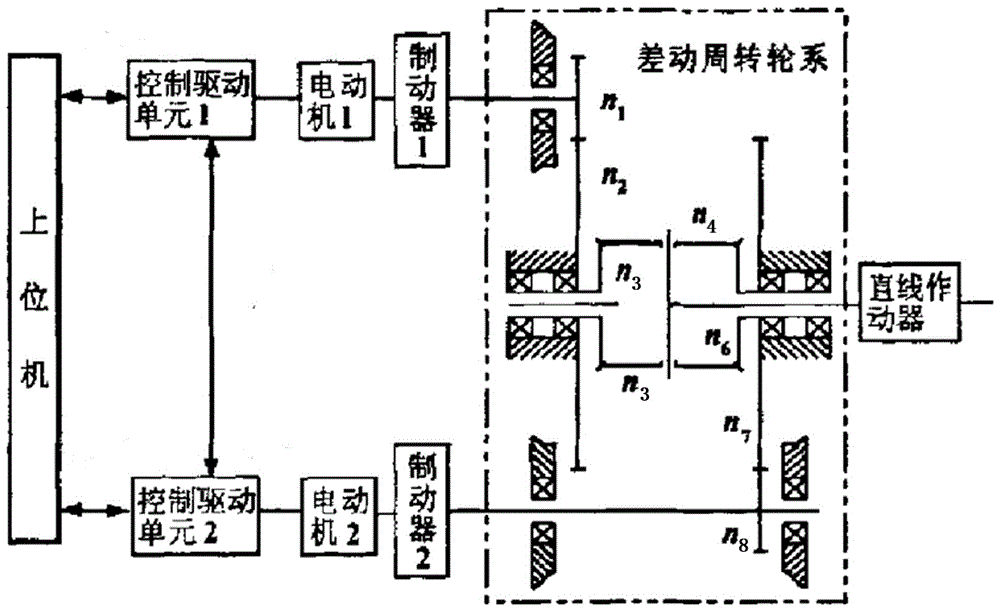

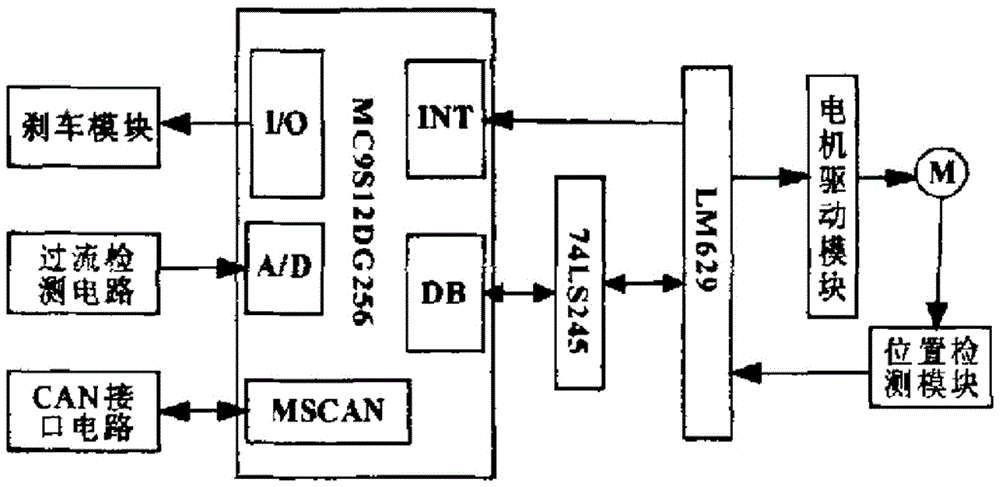

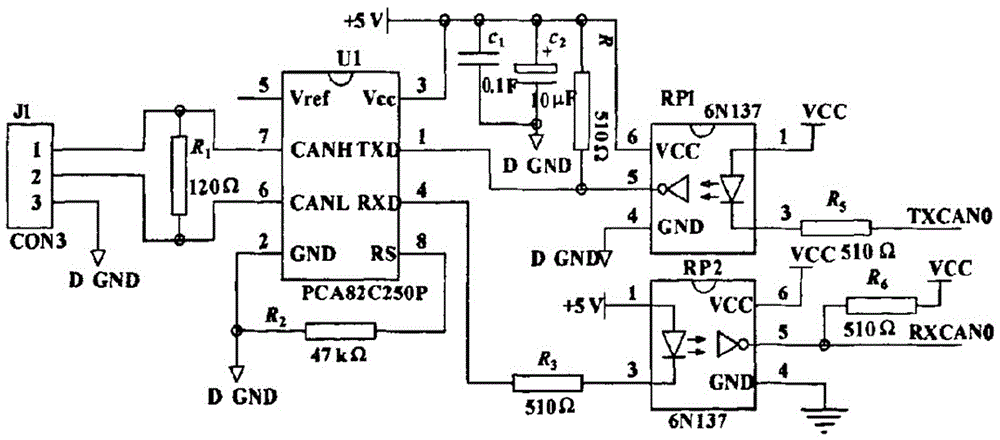

[0020] Such as figure 1 , the upper computer of the control system issues control commands to channel 1 and channel 2 through CAN communication, and information can also be exchanged between channel 1 and channel 2 through CAN communication. Channel 1 and channel 2 connect motor 1 and motor The mechanical motion of 2 is synthesized into the motion of the output shaft, and then the rotary motion is converted into linear motion through the linear actuator, thereby driving the rudder surface to rotate. When the loads of the two channels are unbalanced (that is, the speeds are inconsistent), the differential epicyclic gear train can effectively solve the problem of force disputes, thereby reducing the difficulty of the control system design. Each channel in the steering gear control system is composed of motor, control drive unit and power supply, etc. If any part in one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com