Automatic membrane coating technical process of battery pole group

A technology of battery pole group and process flow, applied in the construction of secondary batteries, lead-acid batteries, lead-acid batteries, etc., can solve the problems of slow PVC film, damage to the health of workers, and increase of side pushing processes, so as to achieve work efficiency High, ingenious structure, to avoid the effect of clutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

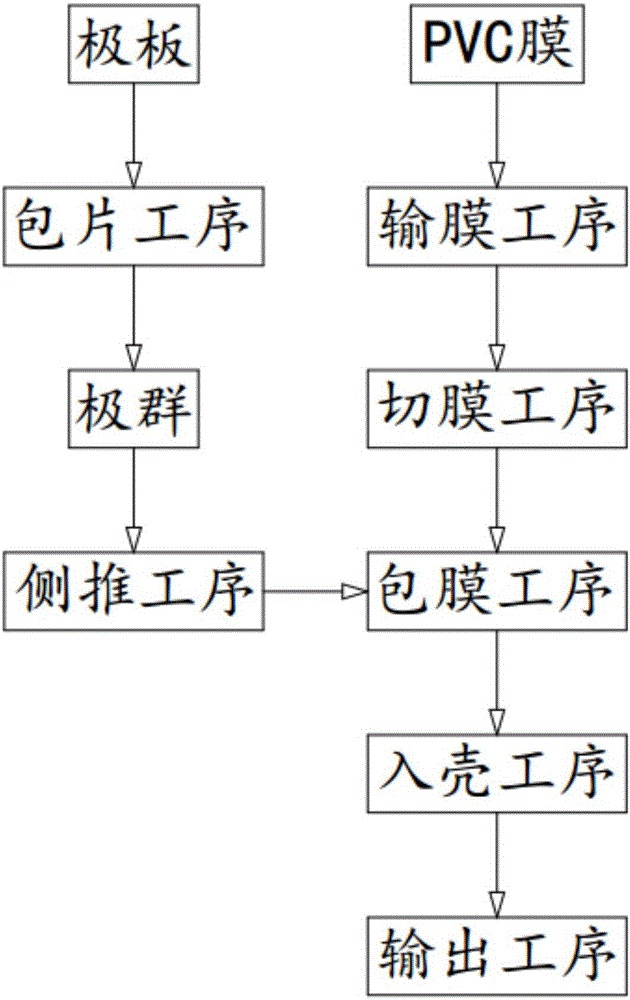

[0045] Such as figure 1 As shown, a battery electrode group automatic coating process, including:

[0046] Step 1, the wrapping process, the wrapping machine 1 stacks the positive and negative plates in sequence, and inserts separator paper between the positive and negative plates to form an electrode group 10, and the electrode group 10 is formed by the conveying channel 12 one by one. sequential delivery;

[0047] Step 2, the side pushing process, the pole group 10 conveyed by the conveying channel 12 is transported to the side pushing station at the end of the conveying channel 12, and the first cylinder 21 vertically arranged to the conveying channel 12 Pushing sideways to push the pole group 10 out of the conveying channel 12;

[0048] Step 3, film delivery process, after the pole group 10 is pushed laterally by the first cylinder 21 onto the carrying roller 33 located on one side of the conveying channel 12, the third cylinder 451 drives the PVC through the second vacu...

Embodiment 2

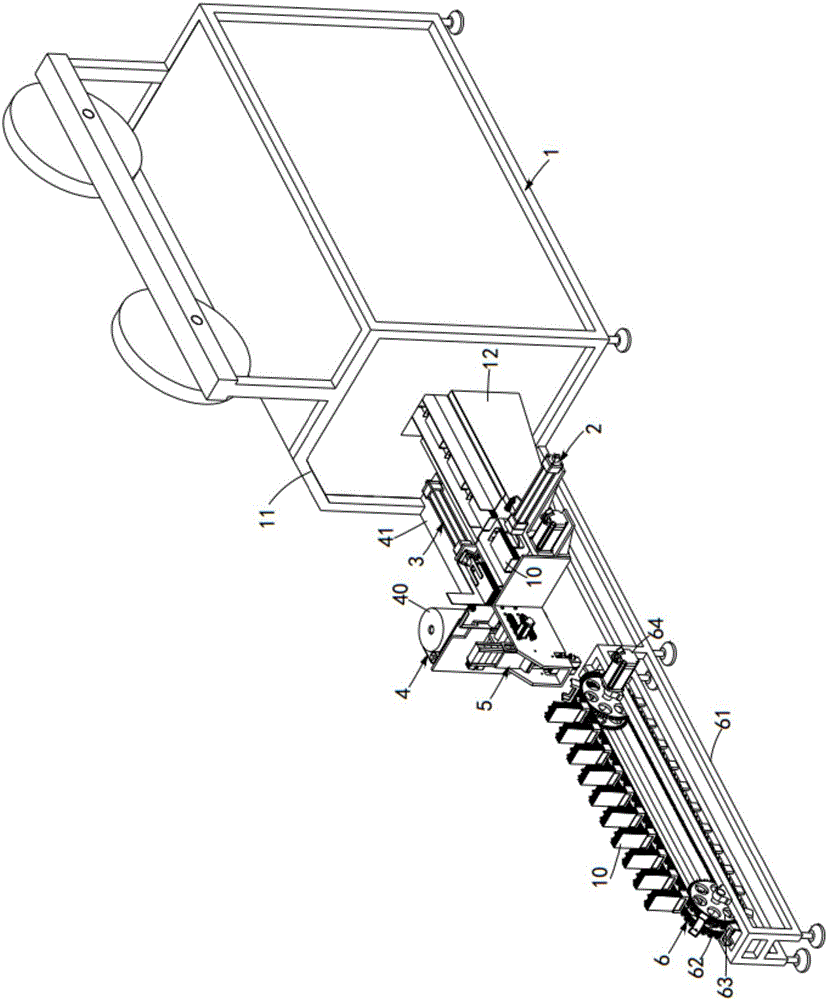

[0063] Reference manual attached figure 1 An automatic coating machine for electrode groups of lead-acid batteries according to the second embodiment of the present invention is described.

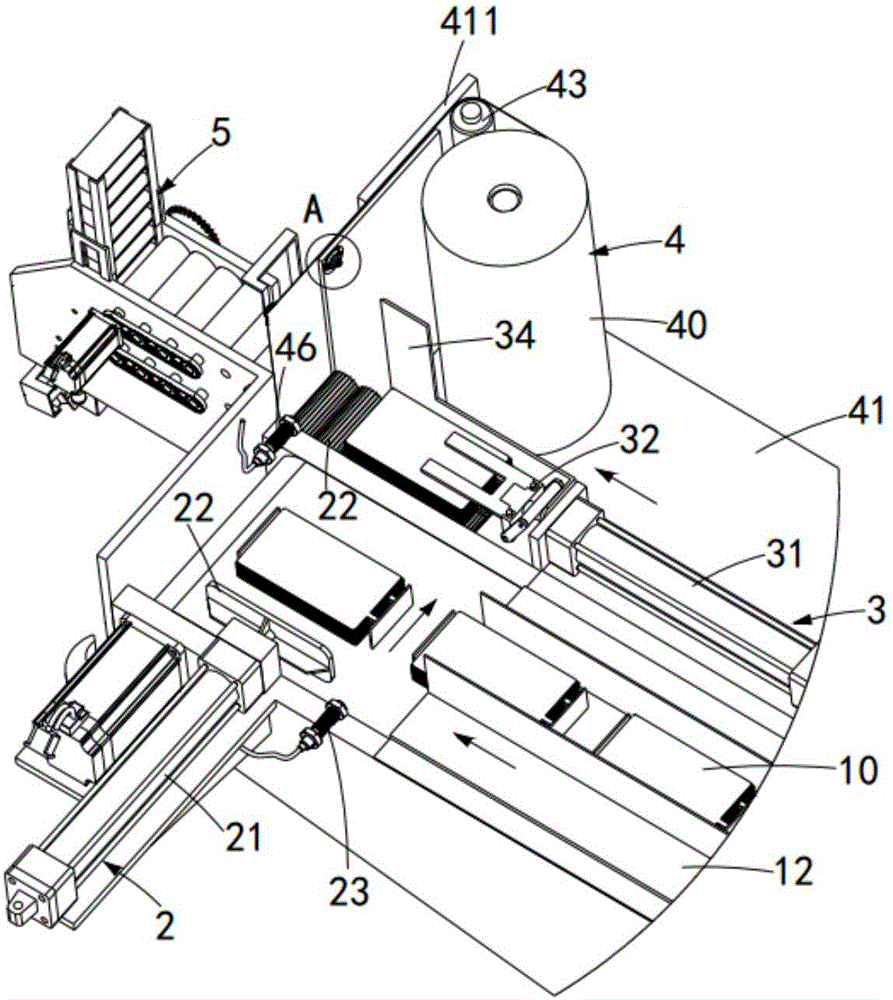

[0064] Such as figure 2 and image 3 As shown, an automatic lead-acid battery pole group coating machine includes a wrapping machine 1. The wrapping machine 1 includes a body 11 and a conveying channel 12, and several pole groups 10 are transported on the conveying channel 12, and also includes:

[0065] The first pushing mechanism 2, the first pushing mechanism 2 is arranged on one side at the end of the delivery channel 12, it is vertically arranged with the delivery channel 12, and it pushes the pole group output by the delivery channel 12;

[0066] The second pushing mechanism 3, the second pushing mechanism 3 is arranged on the other side of the conveying channel 12 relative to the first pushing mechanism 2, it is arranged in parallel with the conveying channel 12, and it pushes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com