Assembling mechanism of power supply module

A power module and assembly mechanism technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of no angle adjustment, troublesome operators, random placement of tools, etc., to facilitate assembly operations, speed up assembly speed, and improve assembly quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

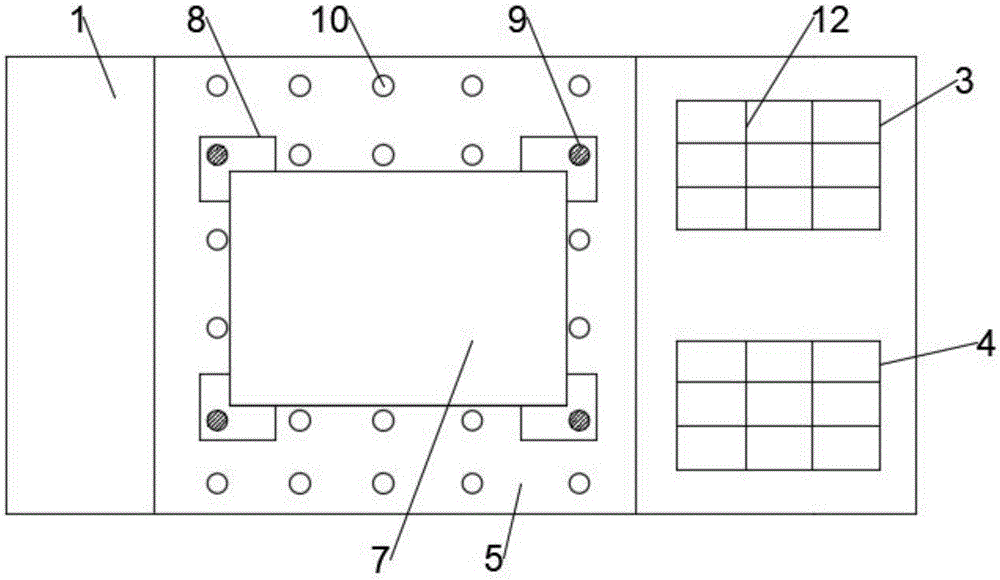

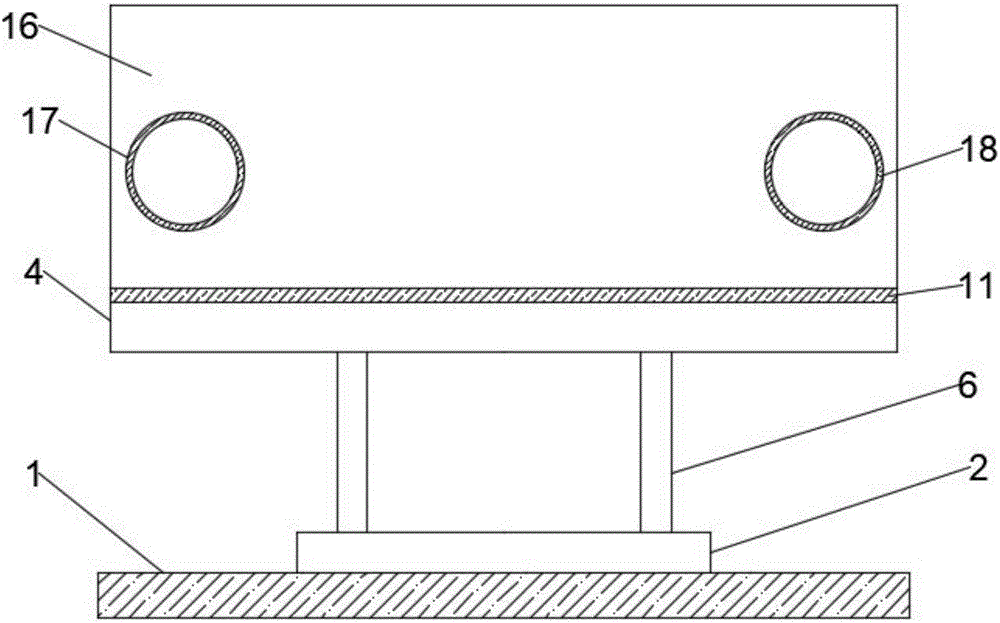

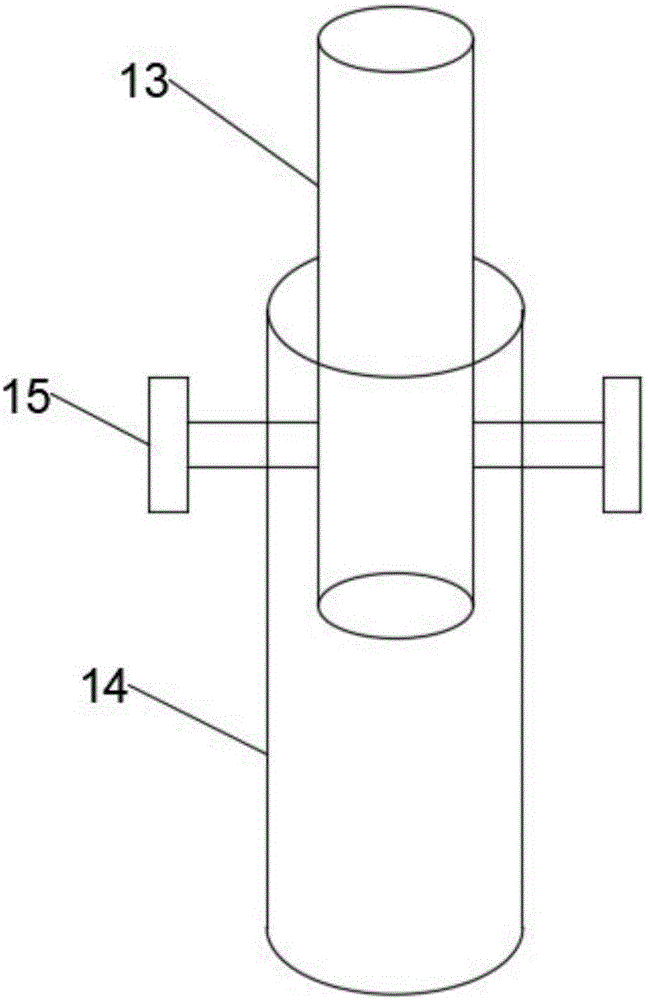

[0026] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses an assembly mechanism of a power module, including a workbench 1, a processing position 2 is provided on the upper surface of the workbench 1, a tool box 3 and a parts box 4 are arranged on the upper surface of the workbench 1 , the tool box 3 is used to place the tools used for assembling the power module, the parts box 4 is used to place the parts required for assembling the power module, and a rectangular operating panel 5 is arranged above the processing position 2, so The operation panel 5 is connected with the processing position 2 through the telescopic rod 6, and the number of the telescopic rods 6 is four. By adjusting the height of different telescopic rods 6, the function of adjusting the angle of the different positions of the operation panel 5 is realized, so that The operating panel 5 is tilted according to the requirements, which is convenient for assembly. The four tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com