Method of measuring carbonation levels in open-container beverages

An open container and measuring instrument technology, applied in the field of measuring carbon dioxide levels in beverages in open containers, can solve the problems of low accuracy and reliability, and achieve the effect of high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

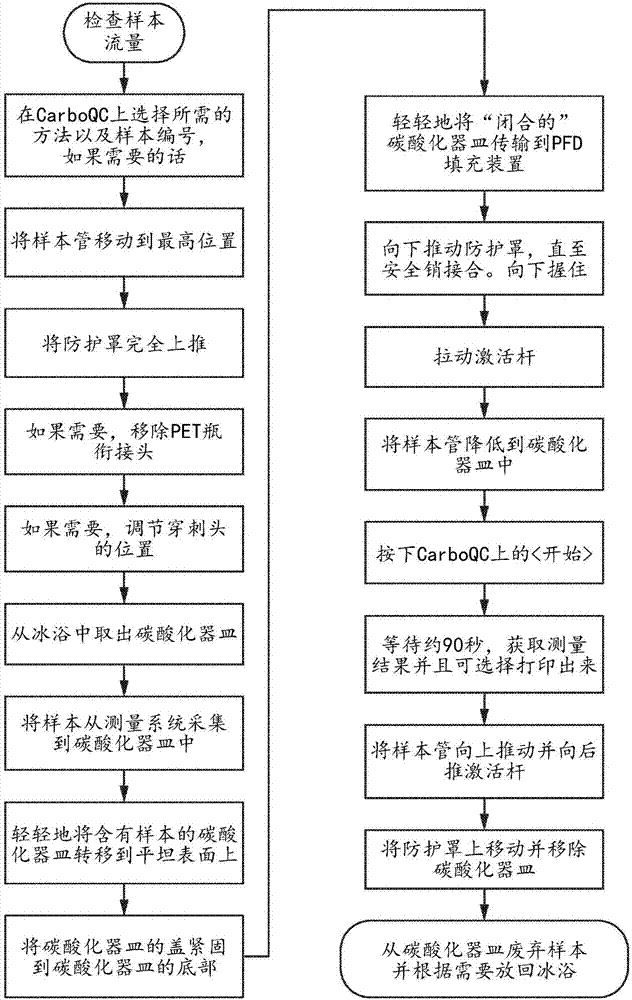

[0060] The following examples are provided for illustrative purposes and they should not be construed as limiting the scope of the invention. refer to figure 1 The flow chart shown in , this example shows a method for measuring carbonation levels in open soft drink cans using the previously described Anton Paar CarboQC instrument equipped with a piercing and filling device (PFD).

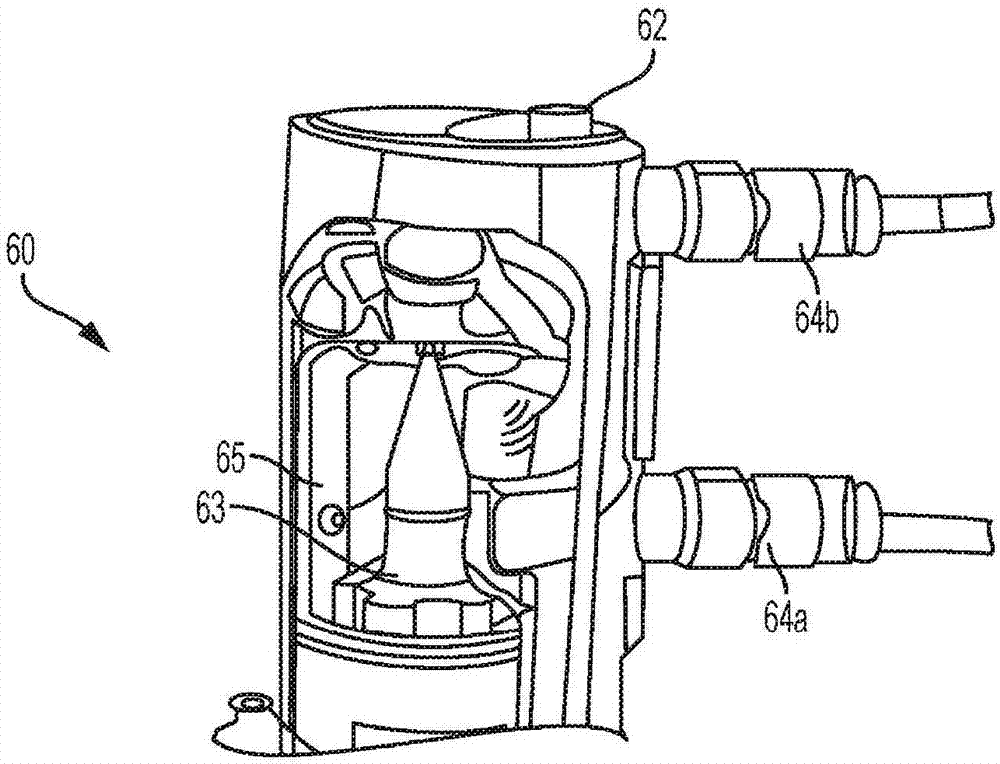

[0061] Sample flow should be checked at the outset. refer to image 3 , the flow through the measuring chamber 65 should be such that approximately 150 mL of sample is consumed when the fill time is set at approximately 30 seconds. The flow can be adjusted by turning the flow valve 62 clockwise to decrease the sample flow and counterclockwise to increase the sample flow. Significantly lower or higher flows can lead to erroneous measurements due to sample carryover or air bubbles in the measurement chamber 65 . Flow should be adjusted as needed before starting the test, but does not need to be ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com