Water concentration type pulverizer for ore mining

A pulverizer and water separation technology, applied in the direction of grain processing, etc., can solve the problems of difficult separation of stone powder, large dust, etc., and achieve the effect of facilitating screen filtration, maintaining the surrounding environment, and taking out conveniently and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

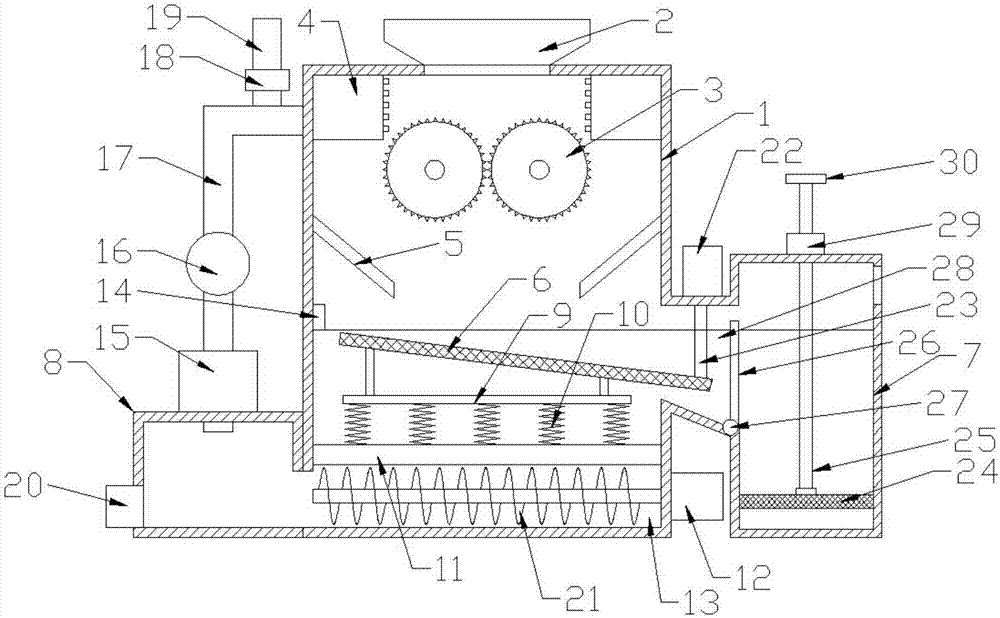

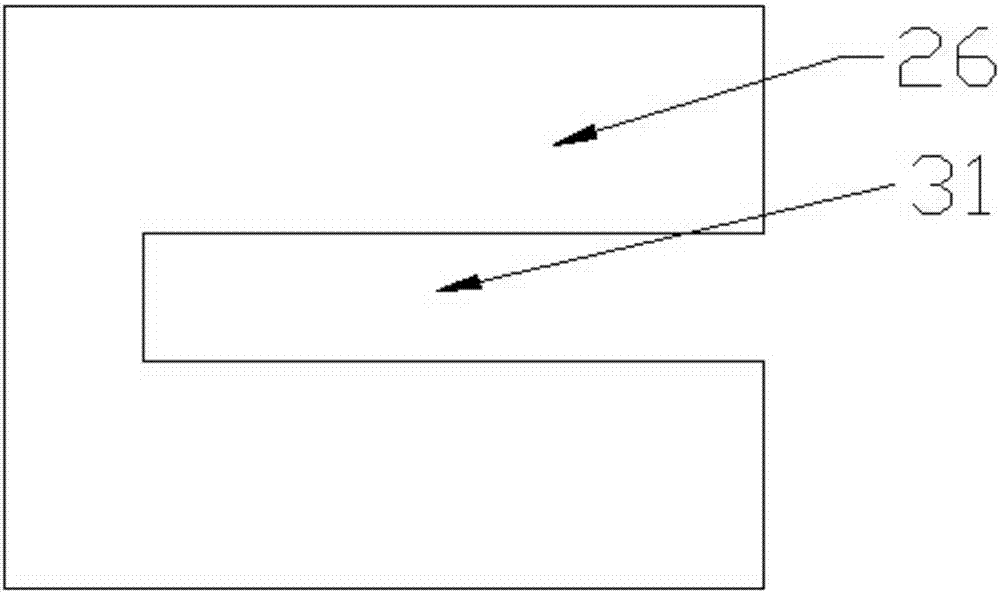

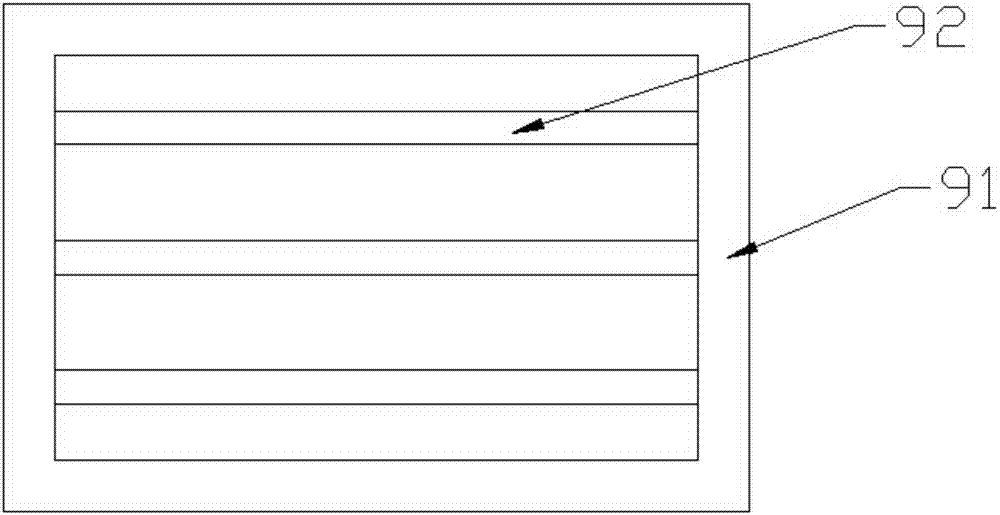

[0019] Please refer to the figure, in the embodiment of the present invention, a pulverizer for water separation type ore development includes a shell 1, a feed hopper 2, a crushing roller 3 and a screen 6; the feed hopper 2 is connected to the shell 1 At the top of the shell 1, facing the feed hopper 2, there are two crushing rollers 3 that are horizontally extruding each other, and a driving device is connected to them, and the falling stones are squeezed and crushed by the rotation of the crushing rollers 3. , the bottom of the crushing roller 3 is located on the inner side walls of the housing 1 and is fixed with a downwardly inclined material guide plate 5, and the material guide plate 5 sends the crushed stones of the crushing roller 3 to the middle part; The lower end of 5 is fixed with inclined screen cloth 6, and screen cloth 6 is fixed on the movable support 9 by support bar, and movable support 9 is made of rectangular frame 91 and fixed rod 92, and fixed rod 92 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com