Industrial robot trajectory planning method avoiding cable interference constraint

An industrial robot and trajectory planning technology, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as cable interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

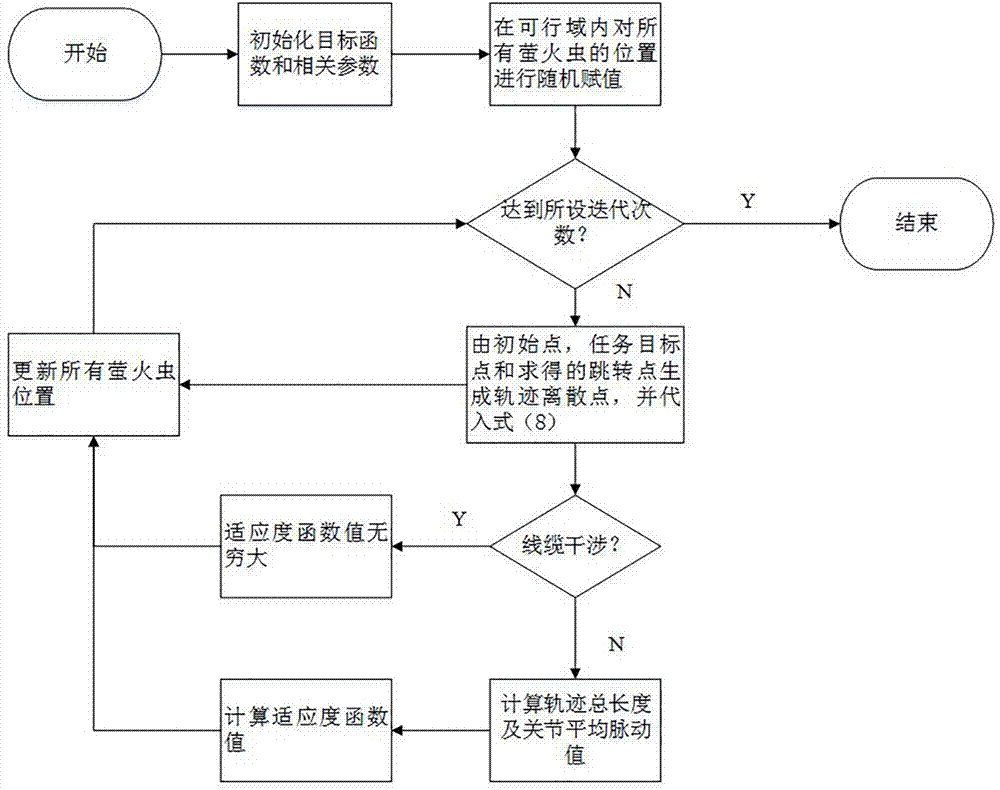

[0056] The process of solving the multi-objective trajectory planning method for an industrial robot with cables based on an intelligent optimization algorithm, the specific implementation steps are as follows:

[0057] Step 1. Establish the robot kinematics model and obtain the positive and negative solutions of the industrial robot;

[0058] The kinematics model is to obtain the D-H parameter information by establishing the coordinate system of each connecting rod, and deduce the positive and negative kinematic solutions according to the transformation relationship of the coordinate system.

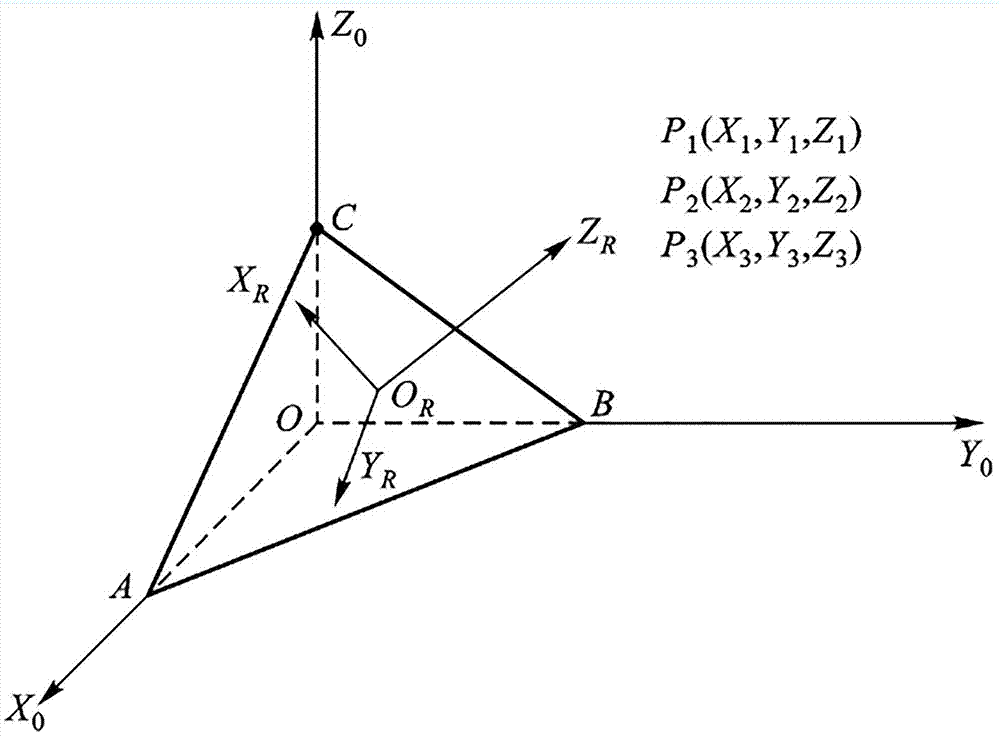

[0059] Step 2. According to the installation position of the cable, the coordinate system of the mobile end and the fixed end of the cable is established, and the homogeneous transformation matrix of the mobile end and the fixed end of the cable is obtained according to the Cartesian space coordinate transformation relationship.

[0060] Step 3. Determine the optimization objective and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com