Method and device for material tracking and slipping detection for feeding belt

A material and belt technology, which is applied in the field of material tracking and slip detection of the feeding belt, can solve the problems of large flow fluctuations of the feeding device, difficulty in cooperation, and increased costs, and achieve a large detection range, strong anti-interference ability, and low cost. Effect

Active Publication Date: 2018-01-05

BAOSHAN IRON & STEEL CO LTD

View PDF10 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical solution solves the technical problems of large flow fluctuations in the feeding device, and the installation of a feeding machine, which raises costs, makes coordination difficult, and wastes materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0085] Install

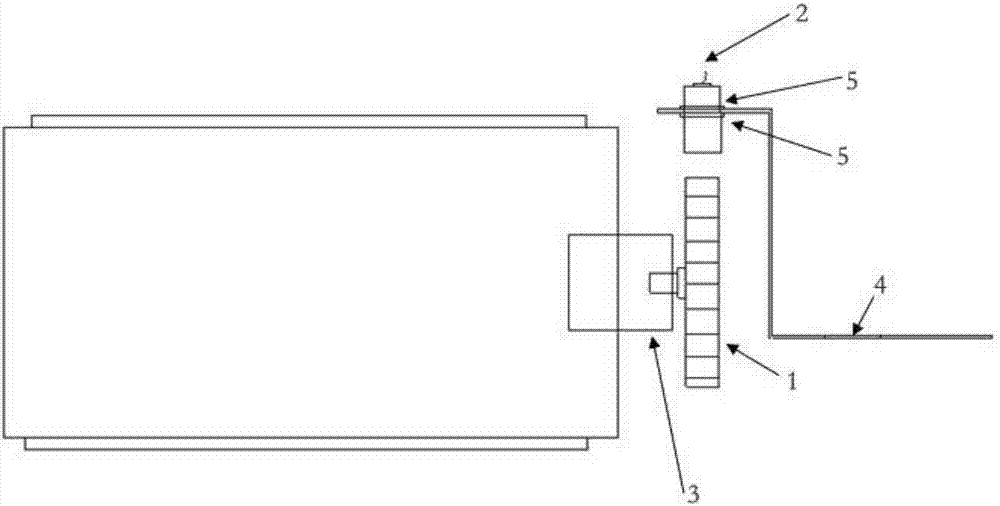

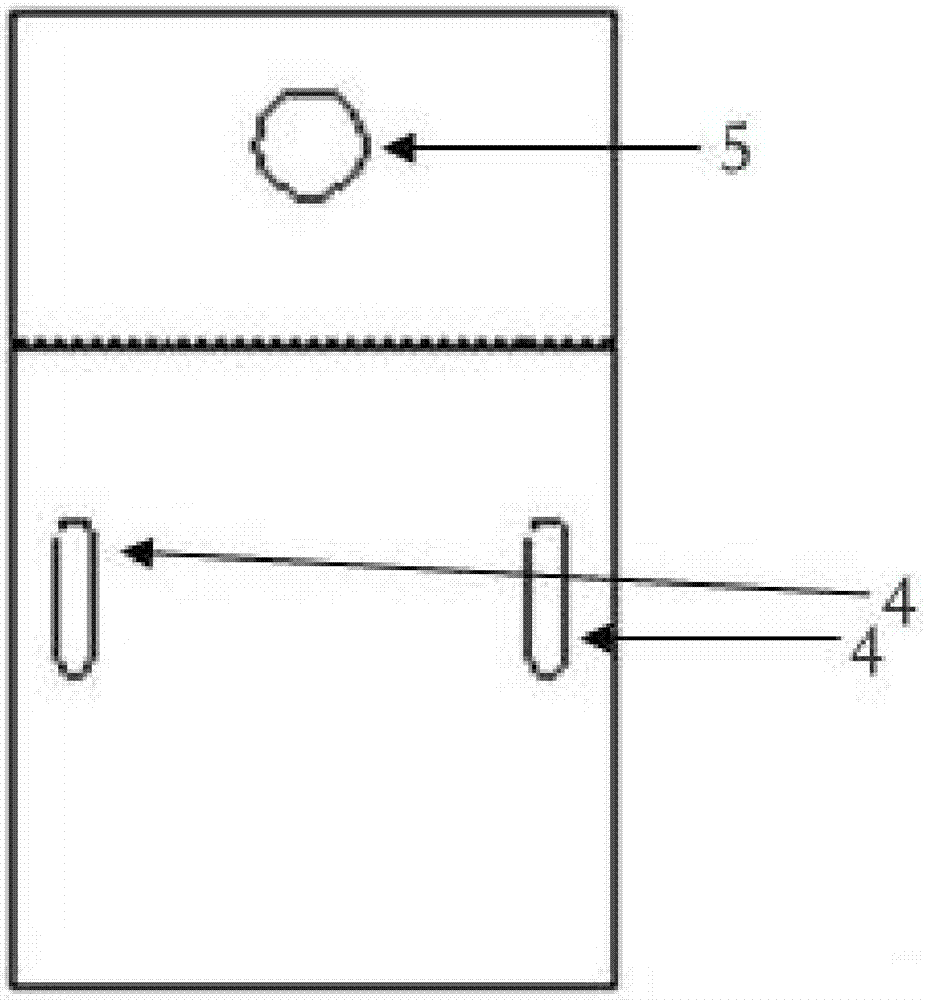

[0086] Install the speed measuring gear and the sensor, among which, the horizontal position can be adjusted through the waist hole, and the vertical position can be adjusted through the adjusting nut, so that the sensor and the speed measuring gear are on the same plane and the distance is appropriate, so that the signal is stable.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

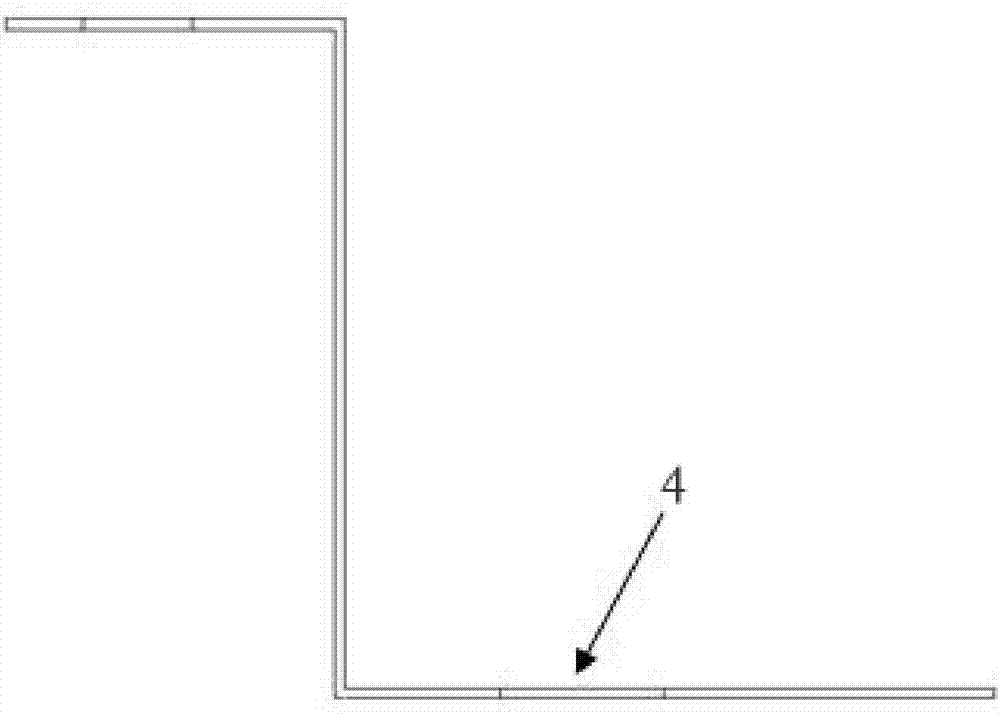

The invention discloses a method and device for material tracking and slipping detection for a feeding belt. The device comprises a material conveying roller, a return roller and a conveying belt, wherein a speed measuring gear is arranged at one end of the return roller, a sensor is arranged on an outer machine frame of the return roller, and the speed measuring gear and the sensor are arranged in the same plane in the vertical direction. According to the method for material tracking and slipping detection for the feeding belt, the same speed sensor is matched with a single-chip microcomputer, a function relation between the speed and time and a function relation between the speed and displacement are utilized to realize simultaneous monitoring of the material tracking and the slipping detection; furthermore, in the method, multiple zero clearing steps are established, accumulative errors are eliminated, so that the data accuracy of the whole process is ensured; and detection pulse precision can be adjusted according to on-site belt working condition requirements so that universality between the belts with different rotating speeds can be ensured.

Description

technical field [0001] The invention belongs to the field of belt conveying, and in particular relates to a method and a device for material tracking and slip detection of a feeding belt. Background technique [0002] In the field of industrial automation, the belt conveyor is a commonly used solid material conveying equipment. In steelmaking production, the auxiliary raw materials and ferroalloy raw materials need to be transported to the furnace top silo through the belt. Among the safety accidents caused by the feeding belt, belt slippage is one of the most common failures of belt conveyors. Belt slippage will cause the motor to run idly, and materials will accumulate at the front end of the belt, which may cause different serious consequences. In order to ensure the safe and reliable operation of the belt conveyor, it is very important to detect the belt slipping fault accurately, timely and sensitively. Although there are various kinds of skid detection and alarm devic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G43/02

Inventor 陆万钧严滨

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com