Lifting sheet-stacking machine for glass production line

A glass production line and lamination machine technology, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problem of lack of storage function and wait for waste, achieve high functional value of equipment, improve product quality, and reduce production waiting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

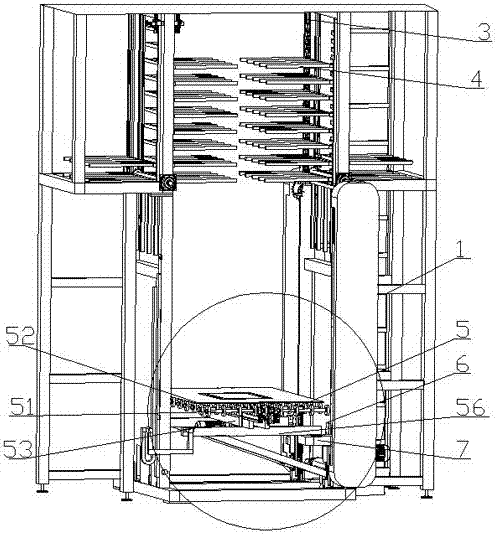

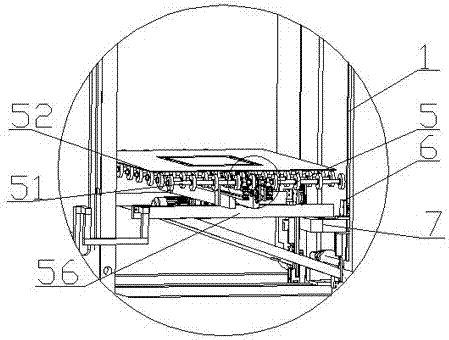

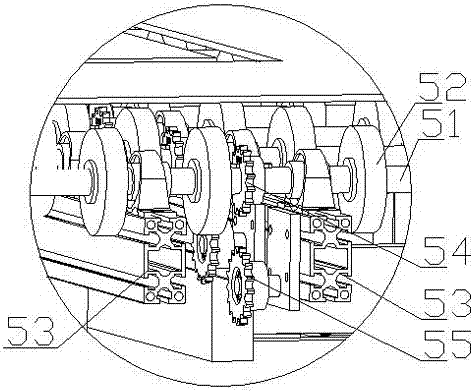

[0017] Such as figure 1 , 2 , 3, and 4, the present invention includes a frame 1, a biaxial output motor, a pair of biaxial output reducers, a pair of rotating lamination devices and a lifting roller conveyor frame 5, a biaxial output motor and a pair of biaxial output The reducers are detachably installed on the top of the frame 1, and the power output shafts of the dual-axis output motors are respectively connected to the power input ends of a pair of dual-axis output motors. The flipping lamination device includes a pair of sprockets 3 and a A set of glass brackets 4 is composed of a pair of gears at one end of the sprocket 3 installed on one side of the frame 1 through a shaft, a pair of bearings and a pair of bearing seats, and a set of glass brackets 4 are fastened or fixedly welded on the On the sprocket, the gears at the other end of a pair of sprockets 3 are connected to the power output shafts of a pair of double-shaft output reducers. A pair of rotating lamination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com