Underground concrete impounding reservoir heat preservation method

A water storage tank and concrete technology, applied in the field of construction, can solve the problems of waste of production materials, unsatisfactory heat preservation effect, etc., and achieve the effect of widening the use area, avoiding waste, and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

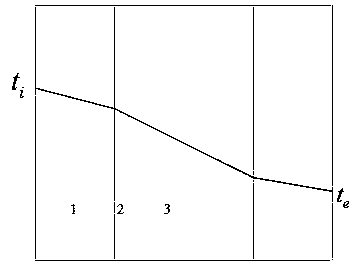

[0057] The climate division of Chengdu is in the hot summer and cold winter area, the annual extreme minimum temperature is -5.9°C, the water temperature in the pool is usually 5°C, and the effective volume of the reservoir is 1000m³ (dimensions are 15.9m×15.9m×4m); the pool wall is thick 250mm, the water storage time is 48 hours; without any heat preservation, the surrounding of the pool and the top of the pool in the pool will dissipate heat to the surrounding environment;

[0058] (1) Calculate the maximum allowable heat loss , where t 2 =5°C, t 1 =0℃, C=4.187kJ / kg·℃, M=1000m³×1000×1.0kg / L=1.0×10 6 kg, the maximum allowable heat loss =4.187kJ / kg·℃×1.0×10 6 kg×(5-0)°C=2.1×10 7 j

[0059] (2) Calculate the average hourly maximum heat loss within the water storage time: =2.1×10 7 kJ / 48h=4.35×10 5 kJ / h;

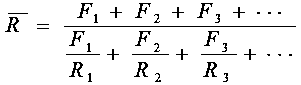

[0060] (3) Calculate the maximum allowable heat transfer coefficient: where q=Q 平 / 3.6=1.2×10 5 kW; The surface area of the 1000m³ pool roof and the surroun...

Embodiment 2

[0072] Lanzhou City, Gansu Province is located in Zone A of the cold region, the annual extreme minimum temperature is -21.7°C, the water temperature in the pool is usually 5°C, and the effective volume of the reservoir is 1000m³ (dimensions are 15.9m×15.9m×4m); the wall thickness of the pool is 250mm , water storage time 48h;

[0073] The calculation process is the same as in Example 1, and it can be concluded that the actual heat transfer coefficient K' (8.1kW / ㎡·℃) > the maximum allowable heat transfer coefficient K (5.92kW / ㎡·℃);

[0074] In the selection of thermal insulation materials, in line with the range of K<K'<2K, the thermal insulation materials should be 0~60mm thick extruded polystyrene board or 0~80mm rock wool board;

Embodiment 3

[0076] Xilinhot City, Inner Mongolia is located in Zone B, a severe cold area. The annual extreme minimum temperature is -38°C, and the water temperature in the pool is usually 5°C. The effective volume of the reservoir is 1000m³ (dimensions are 15.9m×15.9m×4m); the wall thickness of the pool is 250mm, Water storage time 48h;

[0077] The calculation process is the same as in Example 1, and it can be concluded that the actual heat transfer coefficient K' (8.1kW / ㎡·℃) > the maximum allowable heat transfer coefficient K (3.68kW / ㎡·℃);

[0078]In the selection of insulation materials, it is in line with the range of 2K<K'<3K, and the insulation materials are 60~120mm thick extruded polystyrene board or 80~160mm rock wool board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com