Self-reset energy dissipation device

A self-reset, energy-consuming technology, applied in building components, earthquake resistance, building types, etc., can solve the problems of high repair cost, high price, complicated application process, etc., and achieves high precision requirements, simplified operation process, and complicated application process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

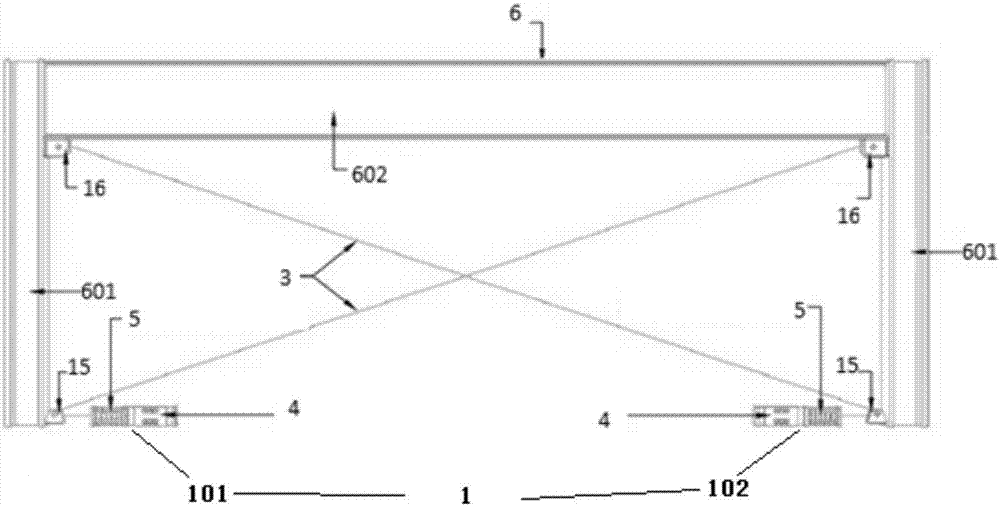

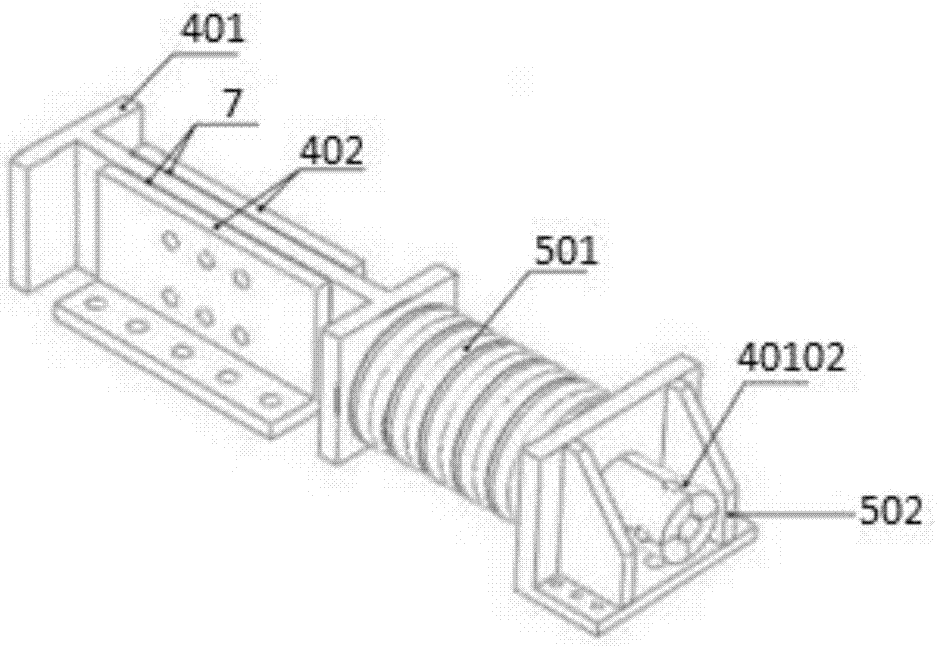

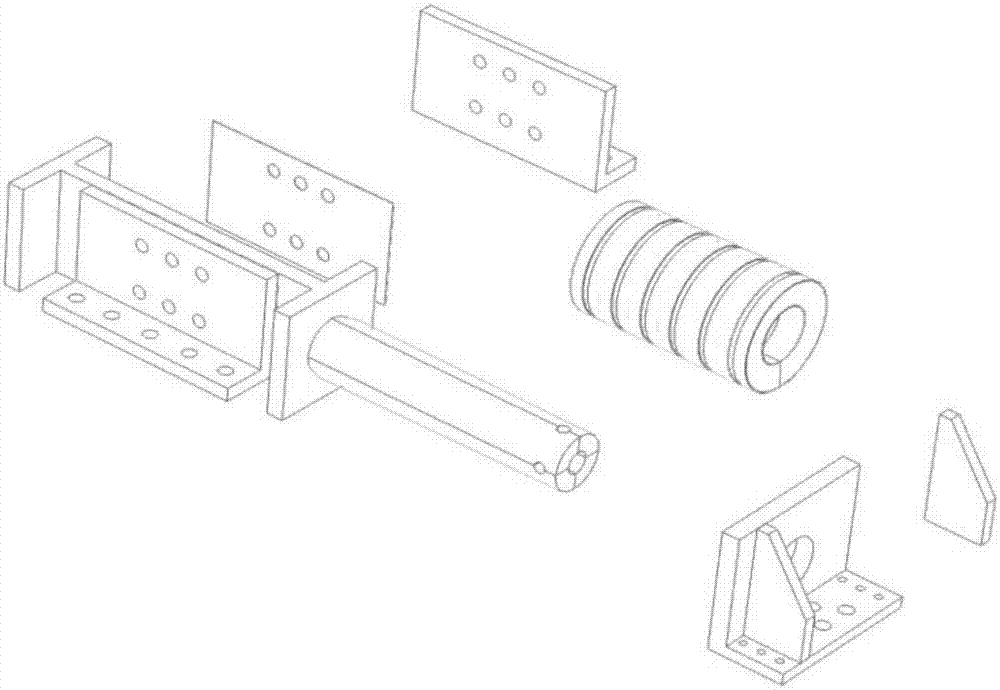

[0037] The self-resetting energy dissipation device is used in the construction frame to resist lateral force energy dissipation and shock absorption, and protect the main structure from damage. see figure 1 , the construction frame 6 includes a frame beam 602, the two ends of the frame beam 602 are respectively provided with a frame column 601, the self-resetting energy dissipation device of the present invention includes a self-resetting energy dissipation mechanism 1 symmetrically arranged on the construction frame 6; each self-resetting The energy dissipation mechanism 1 includes a fixed pulley 2, a plurality of steel cables 3, a friction energy dissipation member 4 and a self-resetting member 5, wherein the fixed pulley 2 is installed on the ground or the floor at the bottom end of a frame column 601 of the construction frame 6, and each One end of each steel cable 3 is fixed at the node formed by another frame column 601 and frame beam 602 , and the other end of each ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com