Engaging type composite energy dissipation and seismic mitigation assembly type wall

A prefabricated and meshing technology, applied in the direction of walls, earthquake-proof, building components, etc., can solve the problems of local damage of deformation joints, poor sound insulation effect, difficult to repair, etc., to speed up the construction speed, improve the seismic capacity, and improve the energy consumption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

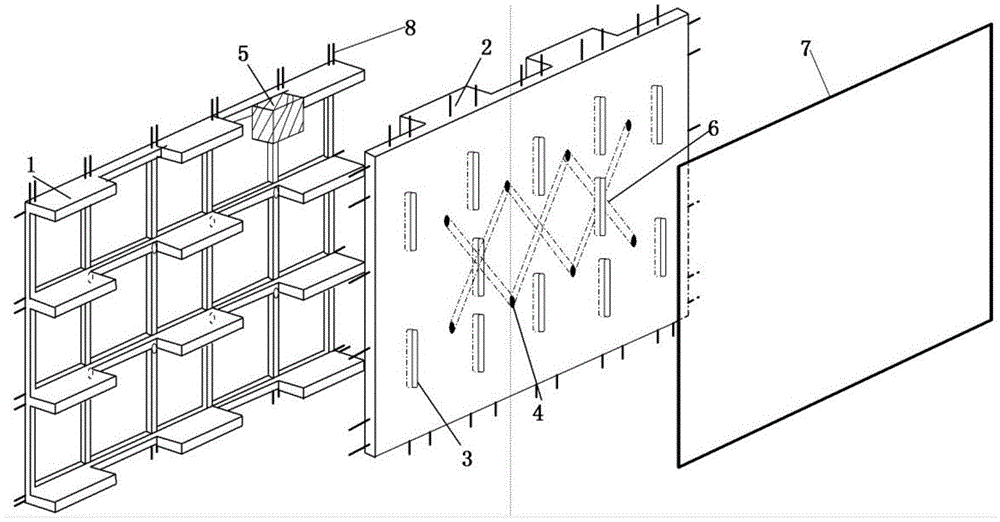

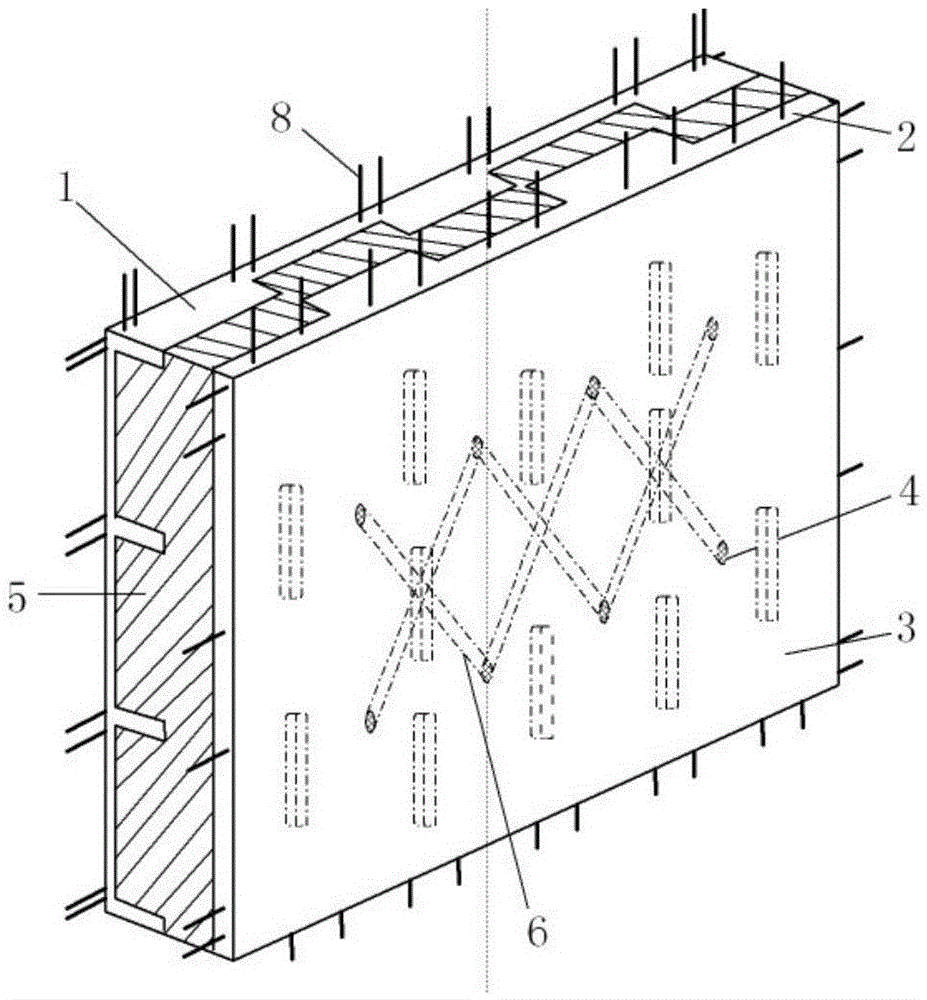

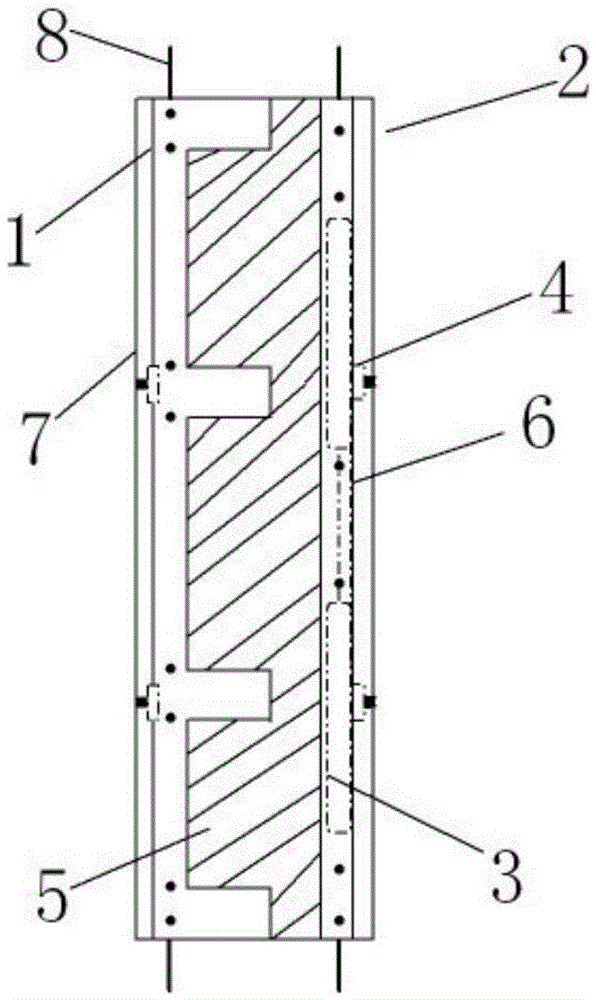

[0041] Such as figure 1 Shown is an embodiment of the meshing composite energy dissipation assembly wall of the present invention, which mainly includes a precast reinforced concrete ribbed wall with a convex-concave shape 1, a precast reinforced concrete shock-absorbing wall with a convex-concave shape 2, a vertical Deformation joint 3, anchor bolt 4, glass fiber concrete 5, cross-type low yield point steel bar 6, thermal insulation sheet 7, lap steel bar 8. The two walls are staggeredly meshed and connected by anchor bolts 4.

[0042] The first stage:

[0043] For a certain nine-story reinforced concrete frame structure, the parameter design stage is carried out according to the requirements of the design specification. The height and width of the specific wall are determined to be 300cm and 600cm respectively, the wall thickness is 24cm, and the anchor bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com