New type environment-friendly boiler

An environmental protection, boiler technology, applied in lighting and heating equipment, combined devices, fluid heaters, etc., can solve the problems of waste of resources, waste of fuel, loss of heat from flue gas, etc., to save the cost of use, avoid waste of resources, and protect air quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

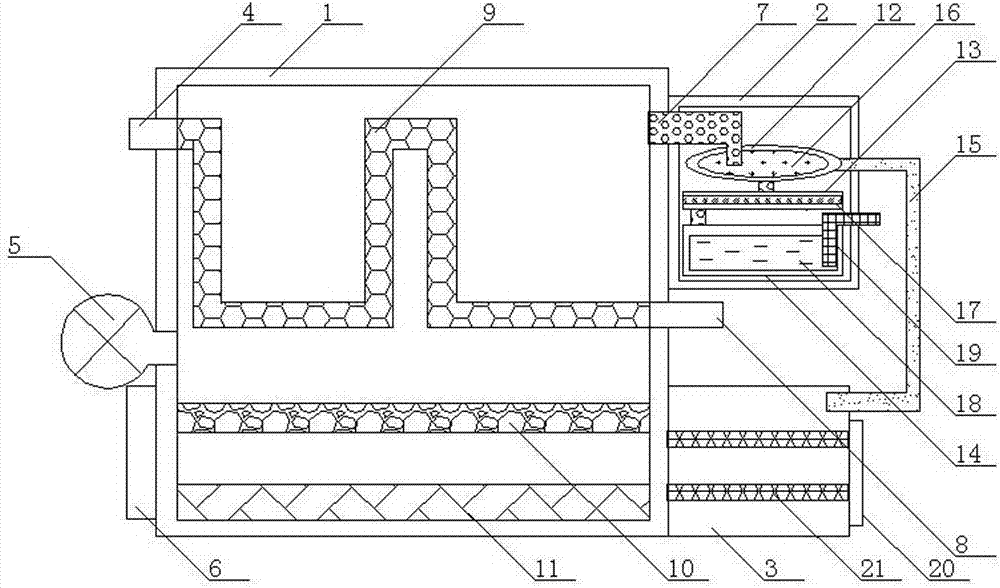

[0013] As shown in the figure, a new type of environmentally friendly boiler includes a furnace body 1, a clean room 2, and a preheating room 3. The left side of the furnace body 1 is sequentially equipped with a water inlet pipe 4, a blast device 5, and a cleaning door 6. The upper end of the right side of the body of furnace 1 is connected to the clean room 2 through the flue gas pipe 7, the middle end of the right side of the body of furnace 1 is equipped with a water outlet pipe 8, and the lower end of the right side of the body of furnace 1 is equipped with a preheating chamber 3; Inside the body 1, a heating elbow 9, a fire grate 10 and an ash cleaning box 11 are sequentially installed from top to bottom; the right end of the water inlet pipe 4 is connected to the left end of the heating elbow 9, and the right end of the heating elbow 9 is connected to the Outlet pipe 8 left end nozzles.

Embodiment 2

[0015] As shown in the figure, a heat exchange area 12, a filter area 13, and a water bath area 14 are sequentially arranged inside the clean room 2 from top to bottom, and the bottom end of the heat exchange area 12 is connected to the filter area 13 through a flue gas pipe 7. The bottom end of the filter area 13 is connected to the water bath area 14 through the flue gas pipe 7; the right end of the heat exchange area 12 is connected to the preheating chamber 3 through the heat transfer pipe 15; the heat exchanger 16 is installed inside the heat exchange area 12, and the filter area 13 An activated carbon filter stick 17 is installed inside, and a miniature water tank 18 is installed inside the water bath area 14; a smoke exhaust pipe 19 is installed on the right side of the miniature water tank 18.

Embodiment 3

[0017] As shown in the figure, a feed door 20 is installed on the right side of the preheating chamber 3 , and a stainless steel filter screen 21 is installed inside the preheating chamber 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com