Annular coil winding machine

A technology of toroidal coils and winding machines, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc. It can solve problems such as slow winding speed, low production efficiency, and unguaranteed product quality, and achieve precise The effect of controlling the number of winding turns, high production efficiency and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

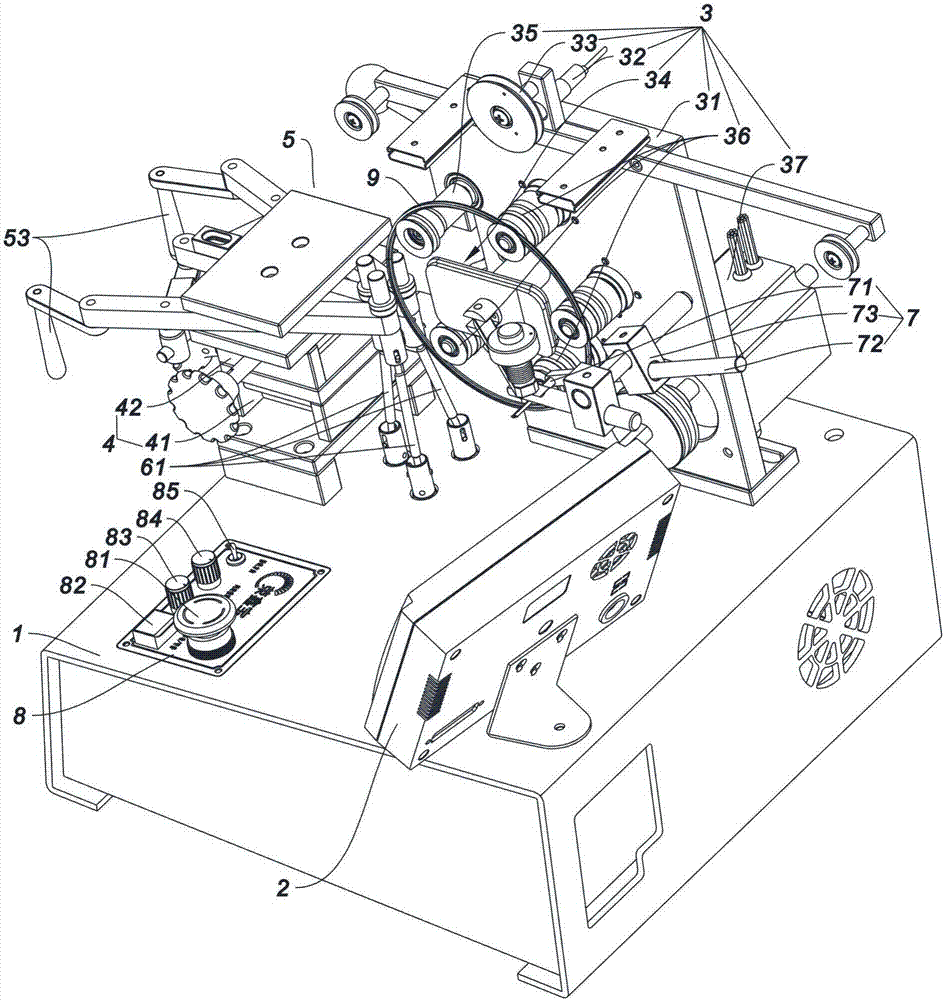

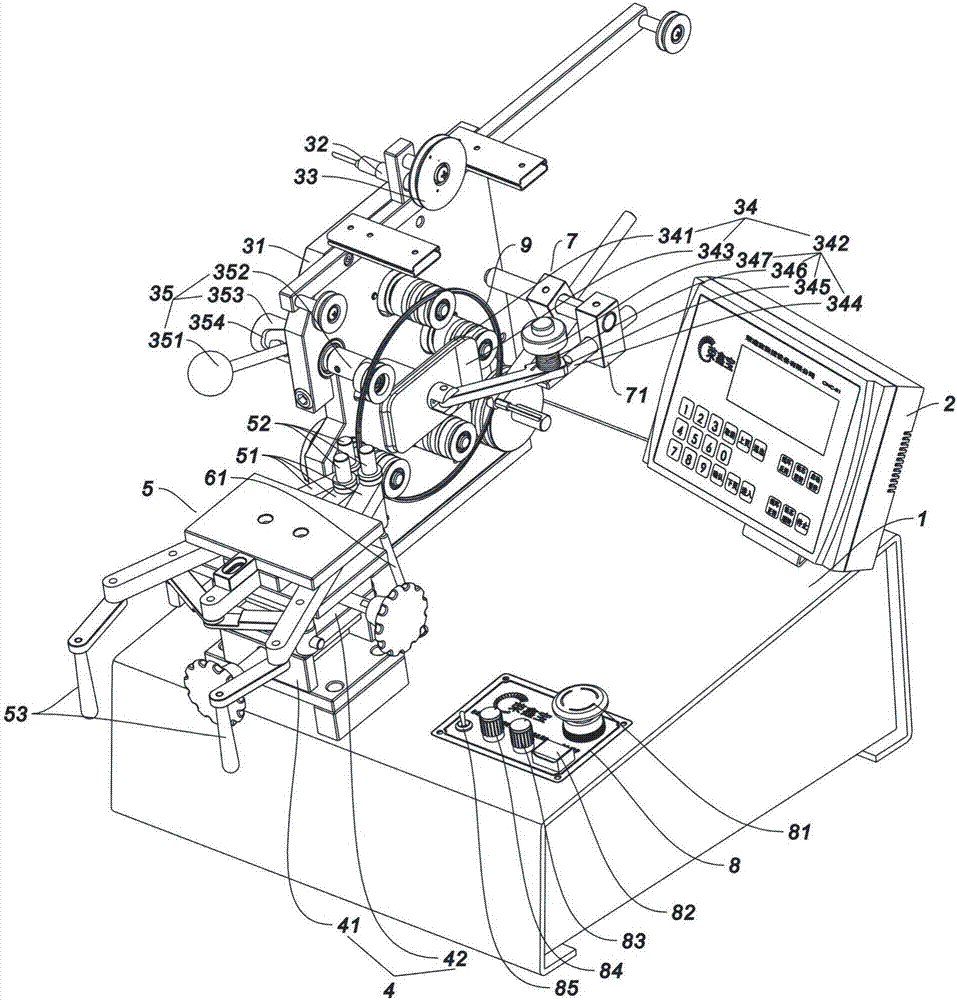

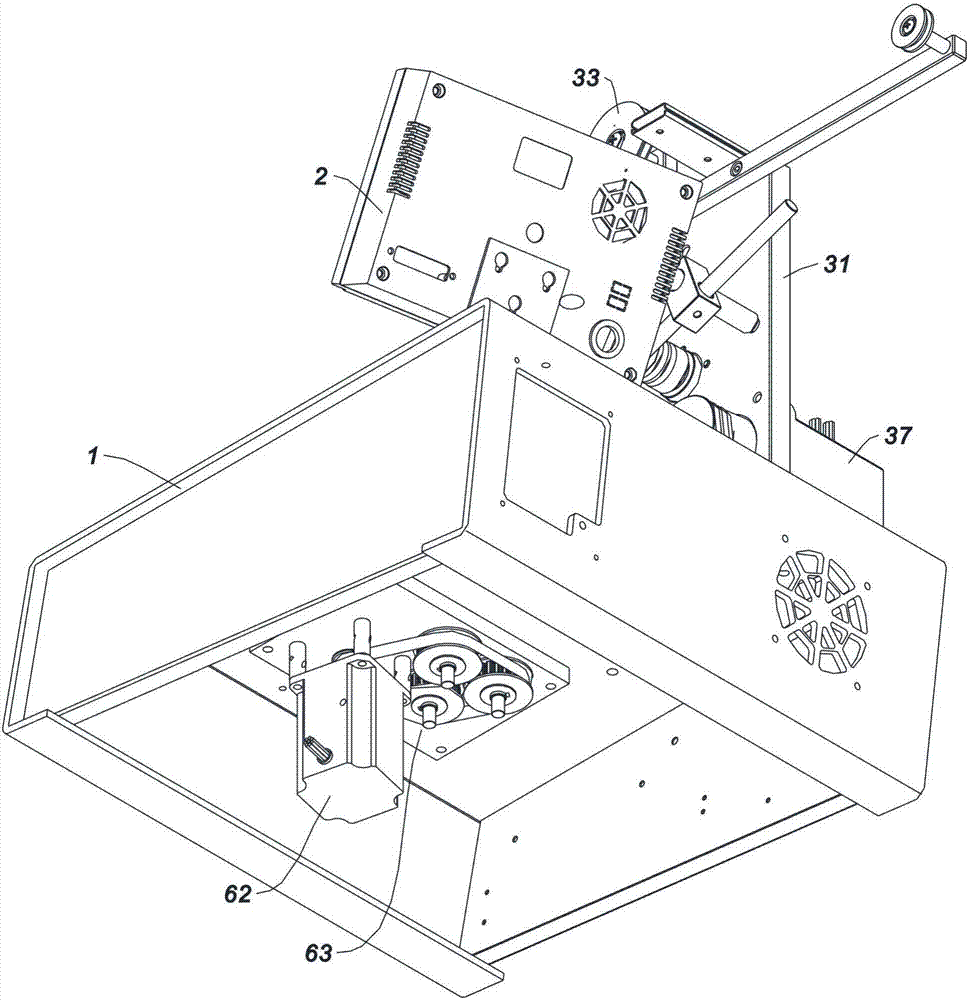

[0025] Such as figure 1 , figure 2 , image 3 As shown, a ring coil winding machine according to the present invention includes a workbench 1, a controller 2, a winding actuator 3, a coil adjustment mechanism 4, a coil clamping mechanism 5, and a coil rotation mechanism, wherein: the coil The adjustment mechanism 4 includes a front and rear adjustment assembly 41 and a left and right adjustment assembly 42. The front and rear adjustment assembly 41 is installed on the workbench 1. The left and right adjustment assembly 42 is installed on the front and rear adjustment assembly 41 and moves forward and backward through the front and rear adjustment assembly 41. The coil clamping mechanism 5 is installed on the left and right adjustment components 42 and moves left and right through the left and right adjustment components 42. The coil clamping mechanism 5 is provided with three elastic jaws 51, and the front ends of each elastic jaws 51 are respectively set There are rubber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com