Integrated machine for scaling fish

An all-in-one machine and fish technology, applied in fish cleaning/descaler, fish processing, slaughtering, etc., can solve problems such as unstable and efficient work, low efficiency, and fish body damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

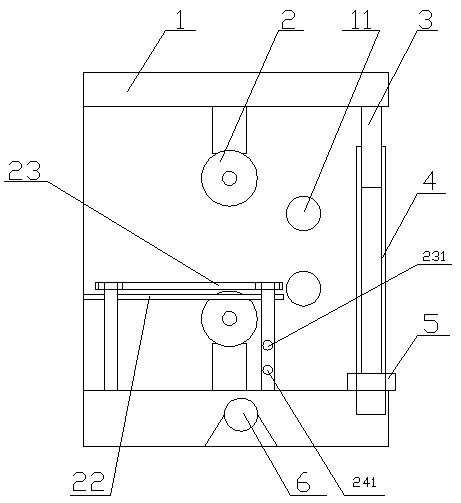

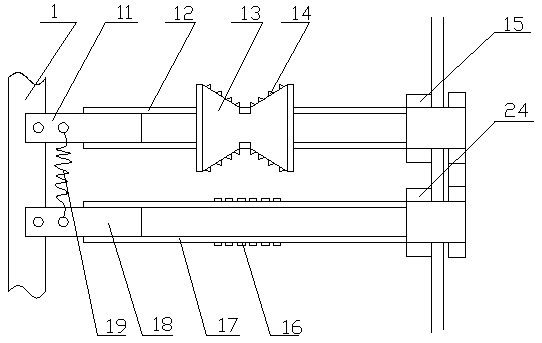

[0047] An integrated fish descaling machine, comprising a frame body 1, a first descaling mechanism arranged on the frame body 1, a cutting mechanism arranged on the frame body 1 and cooperating with the first descaling mechanism, The second descaling mechanism arranged on the frame body 1 and located outside the first descaling mechanism or the cutting mechanism is provided on the frame body for advancing the pushing mechanism 23 for fish processing, And the drive mechanism 6 arranged on the frame body 1 for providing power to the first descaling mechanism, the second descaling mechanism and the pushing mechanism 23 .

[0048] The pushing mechanism 23 includes two pushing modules arranged on the frame body 1 and positioned on both sides of the fish processing direction. The pushing modules include the first pushing wheel 234 arranged on the telescopic module on the inlet side, and the first pushing wheel 234 arranged on the outlet side. The second push wheel 239 on the side, ...

Embodiment 2

[0064] The difference from Embodiment 1 is that the push belt 240 is a chain, and pressing protrusions are arranged on the outside of the chain.

[0065] A guide plate 22 arranged on the frame body 1 and arranged along the fish processing direction.

[0066] The chain that adopts also can adopt the mode of belt pulley of course, and the pressing protrusion that adopts is conventional protrusion structure, promptly welds metal protrusion or other protrusion on it and is used for increasing the frictional force with fish body, and the guide of setting The plate is used for supporting the lower part of the fish body, preventing the fish body from falling downward during processing, and removing fish scales therefrom.

Embodiment 3

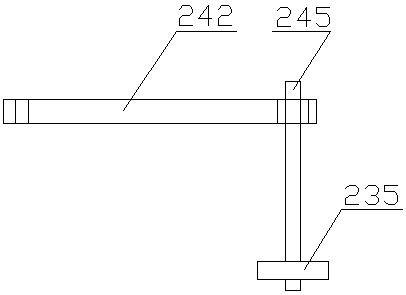

[0068] The difference between it and Embodiment 2 is that the elastic telescopic module includes a support cross bar 243 arranged on the frame body 1, one end is movably connected with the support cross bar 243, and the other end is connected with four bridges of the tensioner rod 245. A rod 242 , an elastic member 244 is provided between the bridging rod 242 and the support cross bar 243 , and the tension wheel 235 is provided at the end of the bridging rod 242 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com