A kind of multilayer embedded solid lipid calcium particle

A technology of solid lipid and microparticles, applied in the field of preparations, can solve many problems such as high bioavailability, good mechanical properties, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

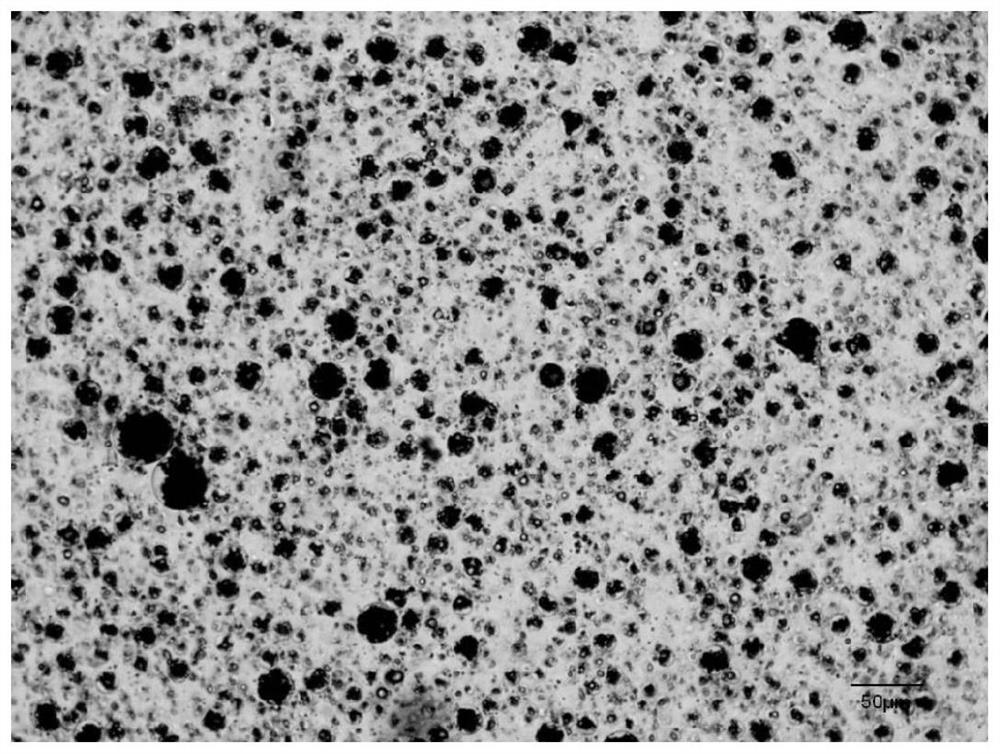

Image

Examples

Embodiment 1

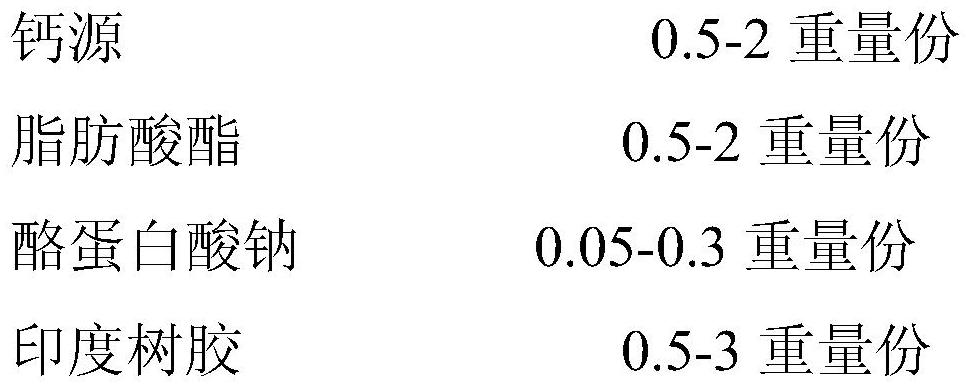

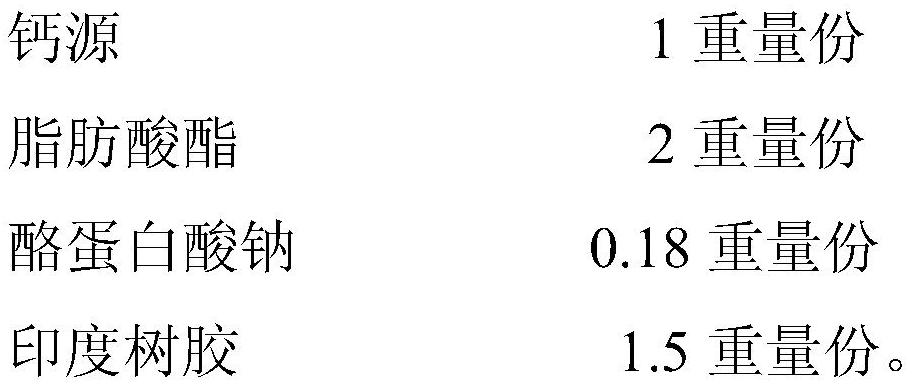

[0028]

[0029] 1) Glyceryl monostearate is mixed with polyglycerol fatty acid ester, heated and melted, then calcium carbonate is added, stirred, and homogenized;

[0030] 2) Sodium caseinate was dissolved in water to prepare 6Kg of sodium caseinate solution with a mass fraction of 3%, and then added to the 3Kg mixture obtained in step 1), heated to 75°C, and homogeneously emulsified;

[0031] 3) Dissolve gum ghatti with water to make 50Kg of gum ghatti solution with a mass fraction of 3%, then add it to the 9Kg emulsion obtained in step 2), heat to 75°C, and emulsify homogeneously;

[0032] 4) Stir the emulsion obtained in step 3) in an ice-water bath, rapidly cool down, then add double the weight of water to dilute it, and then spray dry it to obtain the product.

Embodiment 2

[0034]

[0035] 1) Polyglycerol fatty acid ester is heated and melted, then calcium carbonate is added, stirred, and homogenized;

[0036] 2) Sodium caseinate was dissolved in water to make 15Kg of sodium caseinate solution with a mass fraction of 2%, and then added to the 3Kg mixture obtained in step 1), heated to 80°C, and homogeneously emulsified;

[0037] 3) Dissolve gum ghatti with water to make 150Kg of gum ghatti solution with a mass fraction of 2%, then add it to the 18Kg emulsion obtained in step 2), heat to 80°C, and emulsify homogeneously;

[0038] 4) Stir the emulsion obtained in step 3) in an ice-water bath, rapidly cool down, then add water to dilute it, and spray dry it to obtain the product.

Embodiment 3

[0040]

[0041] 1) Heating and melting glyceryl monostearate, then adding calcium phosphate, stirring, and homogenizing;

[0042] 2) Sodium caseinate was dissolved in water to prepare 5Kg of sodium caseinate solution with a mass fraction of 1%, and then added to the 1.5Kg mixture obtained in step 1), heated to 60°C, and homogeneously emulsified;

[0043] 3) Dissolve gum ghatti with water to make 50Kg of gum ghatti solution with a mass fraction of 1%, then add it to the 6.5Kg emulsion obtained in step 2), heat to 60°C, and emulsify homogeneously;

[0044] 4) Stir the emulsion obtained in step 3) in an ice-water bath, rapidly cool down, then add water to dilute it, and spray dry it to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com