Punch feeding and discharging auxiliary device

An auxiliary device, punching technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of boring working process, increasing motor power and moment of inertia, occupying large volume, etc., to reduce the frequency, shorten the movement distance, The effect of increasing the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

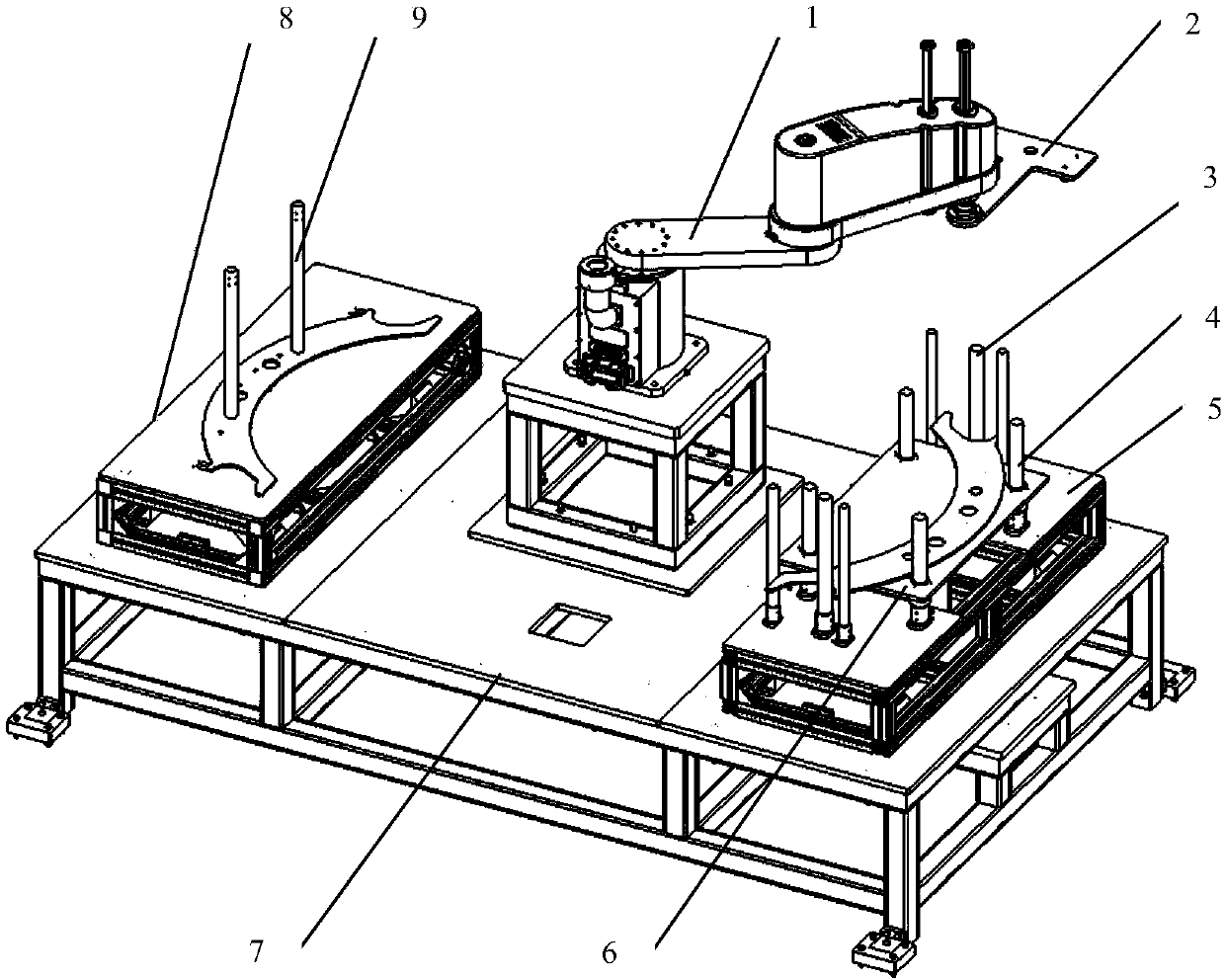

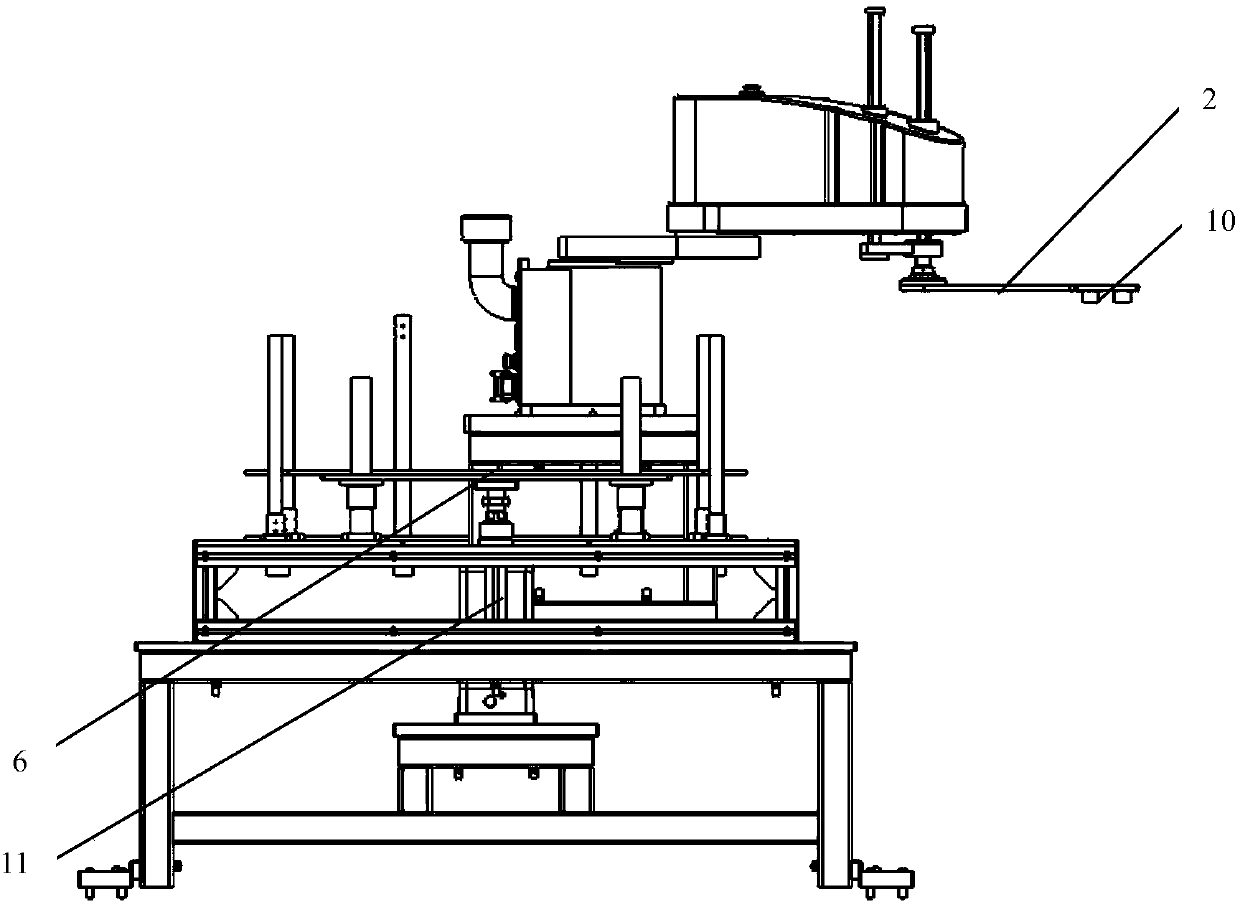

[0012] like Figure 1-Figure 2 As shown, an auxiliary device for loading and unloading on a punching machine includes an installation stand 7, a control cabinet, a four-axis industrial robot 1, a feeding tray and an unloading tray, and the control cabinet is fixed on the bottom of the installation stand 7. In this embodiment, the four The four-axis industrial robot 1 is a SCARA robot, the four-axis industrial robot 1 is installed on the installation stand 7, the end mounting plate 2 is fixed on the end effector of the four-axis industrial robot 1, and the electromagnetic chuck 10 is installed on the end mounting plate 2. Axis industrial robot 1 is arranged between the feeding tray and the unloading tray.

[0013] The control cabinet includes electrical control components, and the control cabinet is used to control the action process of the entire device.

[0014] The four-axis industrial robot 1 has a degree of freedom of movement in the XYZ direction and a degree of freedom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com