Austenitic stainless steel bare welding wire for sodium cooled fast reactor and application of austenitic stainless steel bare welding wire

A technology of austenitic stainless steel and sodium-cooled fast reactor, which is applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of dependence on imports, and achieve the effects of small spatter, stable process and good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

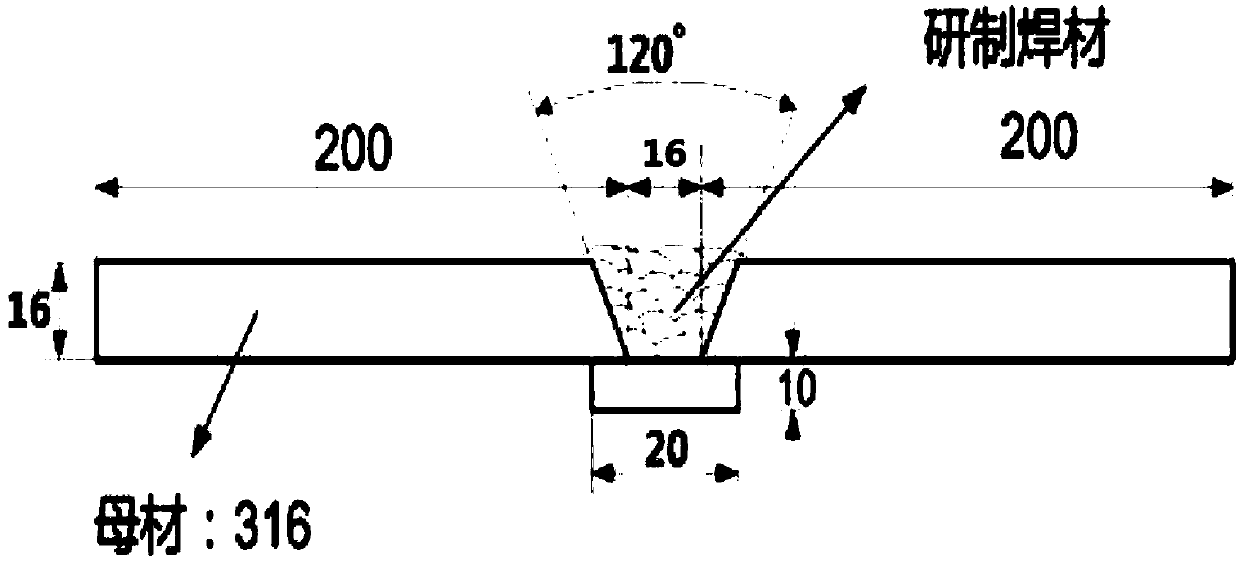

Image

Examples

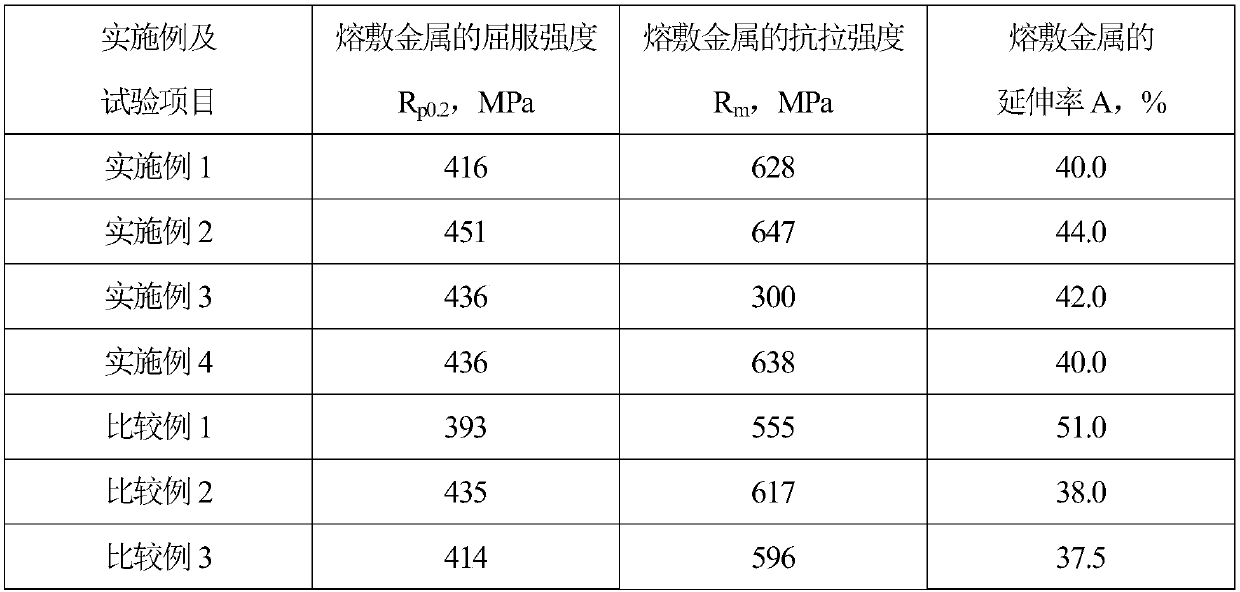

Embodiment 1

[0019] The basic chemical composition of the stainless steel wire is (weight ratio):

[0020] C: 0.042%, Cr: 18.84%, Ni: 12.6%, Mo: 2.49%, N: 0.063%, Mn: 1.59%, Si: 0.42%, Nb≤0.005%, P: 0.004%, S: 0.0007%, The remaining ingredients are iron and unavoidable impurities.

Embodiment 2

[0022] The basic chemical composition of the stainless steel wire is (weight ratio):

[0023] C: 0.058%, Cr: 18.79%, Ni: 12.7%, Mo: 2.45%, N: 0.069%, Mn: 1.59%, Si: 0.47%, Nb≤0.005%, P: 0.004%, S: 0.0007%, The remaining ingredients are iron and unavoidable impurities.

Embodiment 3

[0025] The basic chemical composition of the stainless steel wire is (weight ratio):

[0026] C: 0.043%, Cr: 18.97%, Ni: 12.6%, Mo: 2.48%, N: 0.052%, Mn: 1.57%, Si: 0.43%, Nb≤0.005%, P: 0.004%, S: 0.0015%, The remaining ingredients are iron and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com