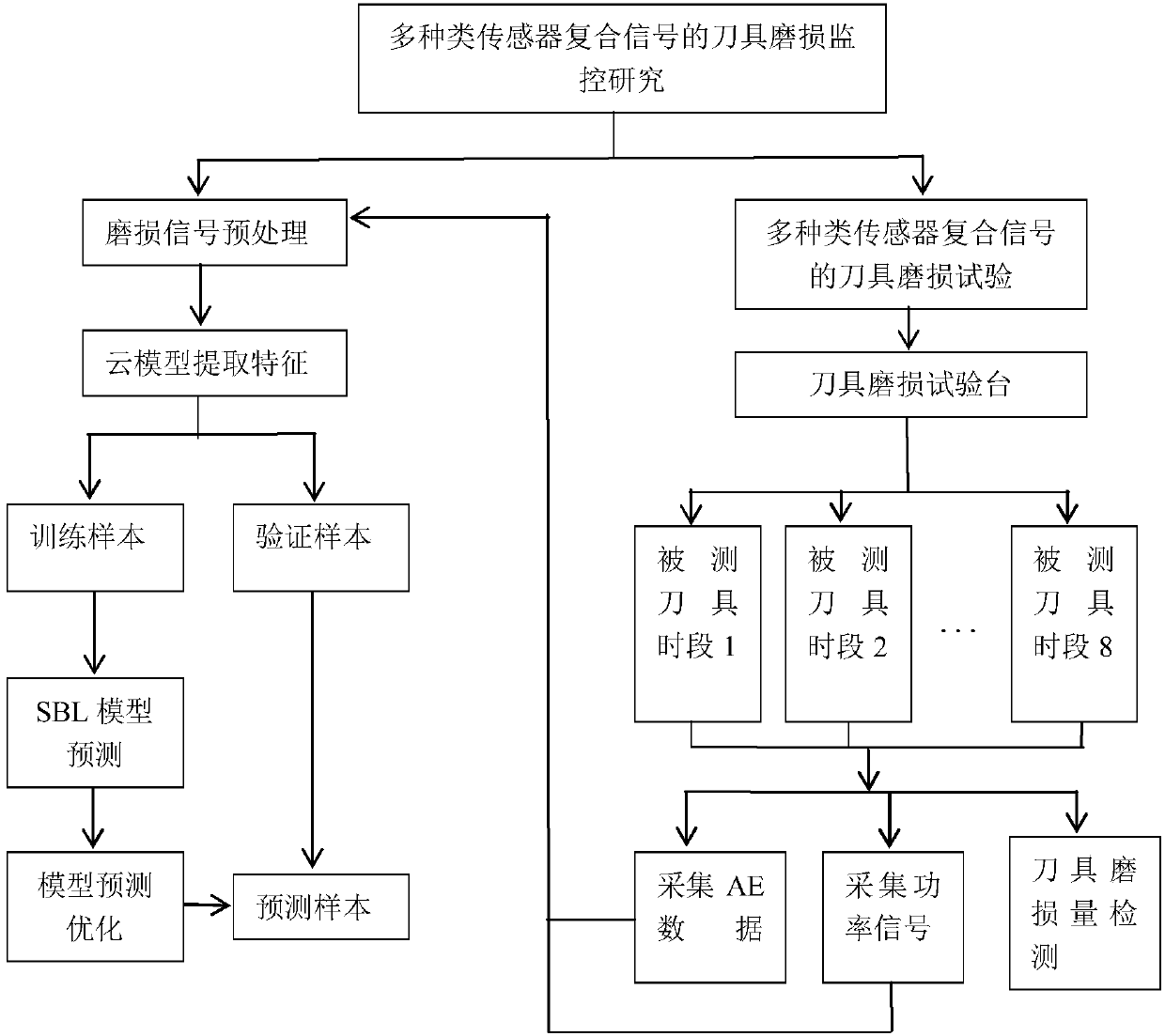

Tool wear monitoring method based on multi-sensor composite signals

A tool wear and composite signal technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of complex models, failure to provide, and prone to over-learning phenomena, and achieve the goal of improving efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

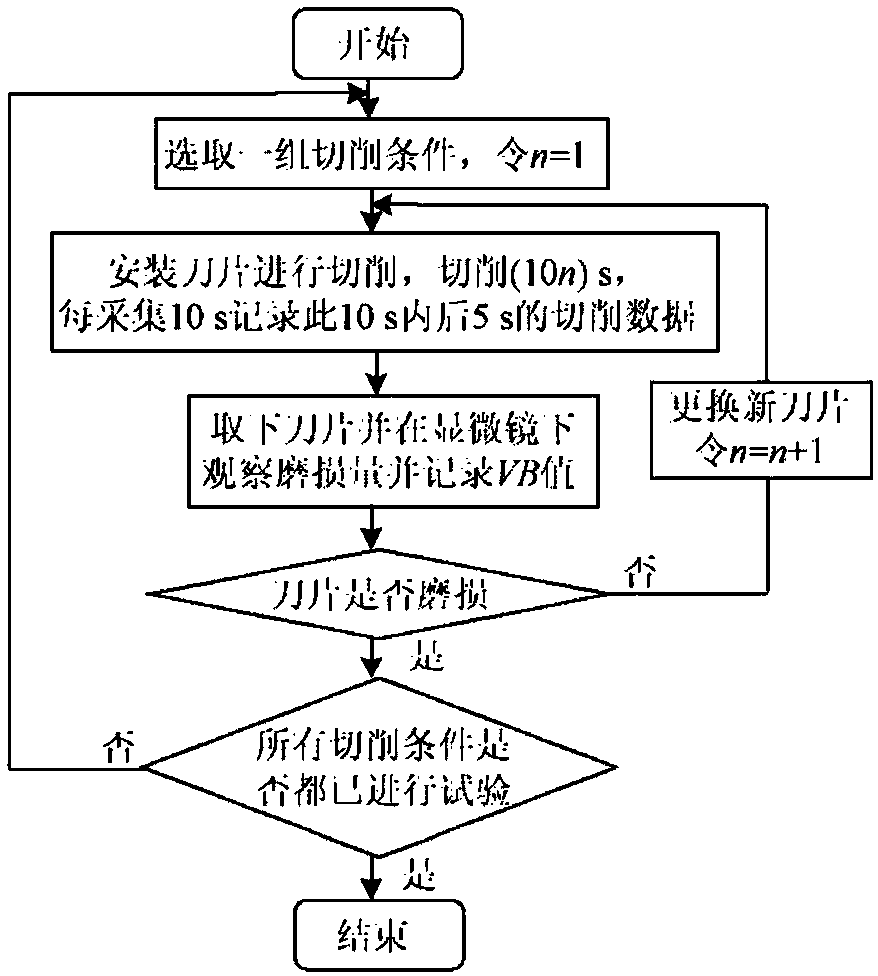

[0014] Step 1 Data collection:

[0015] Use the multi-channel acoustic emission data acquisition system of PAC in the United States to collect data, fix the acoustic emission sensor on the tool box of the test bench through the magnetic base, install a tool in the tool box first, and collect the acoustic emission signal and power signal for 10s; Change the tool, and follow the same steps to collect the acoustic emission signals and power signals of the remaining 8 tools in different periods.

[0016] In order to better study the prediction of the relationship between tool wear state and wear amount under different workpiece processing conditions, if the three cutting parameters (cutting speed, feed rate and back engagement amount) are fully combined, multiple sets of cutting parameters will be generated. conditions, resulting in too large a test volume. Therefore, the orthogonal test method is used to scientifically arrange multiple sets of cutting parameter combination tests...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com