Multi-functional stirring machine

A mixer and multi-functional technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of limited wear resistance of polyurethane sleeves, affecting the normal operation of equipment, and polyurethane sleeves falling off. Improve the smoothness of discharge and the effect of stable shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

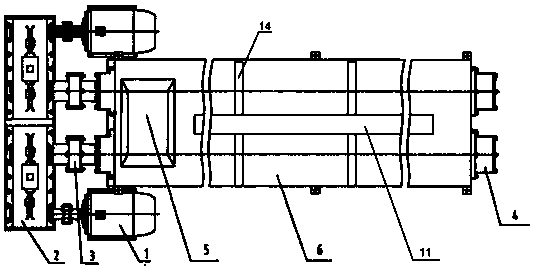

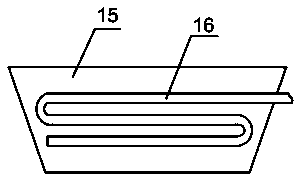

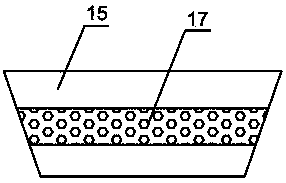

[0021] Such as Figure 1~6 As shown, a multifunctional mixer includes a motor 1 and a mixing box 6, the output shaft of the motor 1 is connected with a reduction box 2, the output shaft of the reduction box 2 is connected with a coupling 3, and the coupling 3 is connected with a stirring shaft 4, and the stirring The shaft 4 is set in the stirring box 6, the motor 1, the reduction box 2, the coupling 3 and the stirring shaft 4 are arranged symmetrically around the center line of the stirring box 6 respectively, the head and tail ends of the stirring shaft 4 are provided with brushes 10, and the stirring shaft 4 There are helical blades 7 on the surface, reverse helical blades 8 are arranged at the intervals of the helical blades 7, and a ribbon blade 9 is arranged on the surface of the stirring shaft 4, and the ribbon blade 9 is formed by buckling two semi-discs with grooves , the outer surface of the mixing box 6 is provided with a sound-absorbing layer 13, the upper surface ...

Embodiment 2

[0026] Such as Figure 1~6 As shown, a multi-functional mixer, in actual work, turn on the motor 1, pour the material into the mixing box 6 continuously through the feed port 5, the motor 1 drives the coupling 3 to rotate through the reduction box 2, and the coupling 3 Drive the stirring shaft 4 to rotate, and the two motors 1 turn in the opposite direction and have the same speed, so that the stirring shaft 4 also rotates in the opposite direction but at the same speed, thereby driving the spiral blade 7, the reverse spiral blade 8 and the ribbon on the stirring shaft 4 The blades 9 roll in opposite directions to stir the materials in opposite directions, and also give the materials a forward force while stirring, so that the materials are pushed to the discharge port 15 while being stirred. During the stirring process, the electric heating belt can be used to 14 Heat the material so that the material can be stirred and dried at the same time, reducing the need for equipment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com