Trough body of hole enlarging trough for cutting silicon slice by diamond line

A technology of diamond wire cutting and trough body, which is applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems of large space occupied by the structure, uneven dispersion of liquid medicine, poor cooling effect of liquid medicine, etc., to achieve space The occupancy rate is small, the overall structure design is reasonable, and the effect of ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

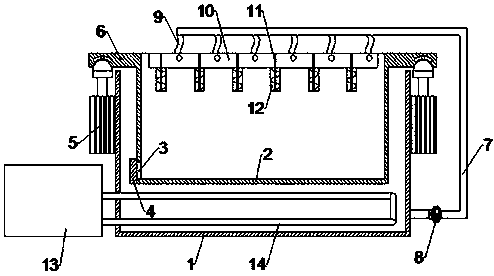

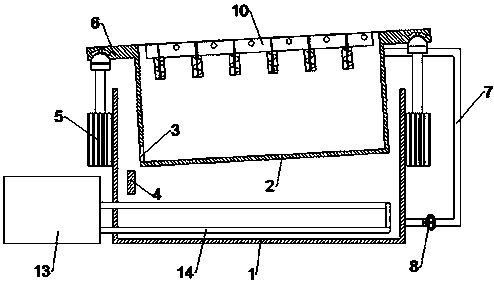

[0028] like Figure 1-5 As shown, a groove body of a reaming groove for diamond wire cutting silicon wafers is characterized in that: it includes an inner groove body 2 and an outer groove body 1 nested inside and outside, and is connected with the outer groove body 1 and extends to the inner groove body 2 The liquid guiding device at the upper end, the liquid inlet device fixed on the inner tank body 2 and the cooling device arranged at the lower end of the outer tank body 1.

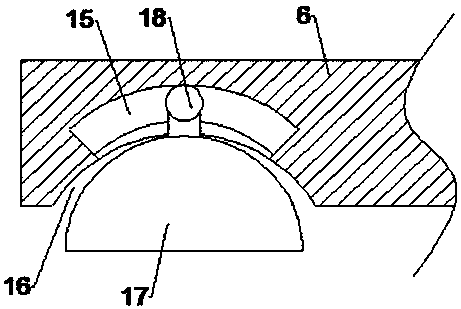

[0029] Among them, a cylinder 5 is respectively fixed on a pair of parallel outer side walls of the outer tank body 1; a bank platform 6 supported on the upper end of the cylinder 5 is respectively extended outward from the side walls at the upper end of the inner tank body 2, and a liquid outlet is provided at the lower end of the side wall at one end. A baffle plate 4 with both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com