Preparation method of glucose crosslinked composite gel and application of glucose crosslinked composite gel to cigarettes

A composite airgel and glucose technology, applied in applications, tobacco, e-liquid filter elements, etc., can solve the problems of cigarette application burial, cumbersome preparation procedures, safety hazards, etc., to increase the adsorption speed and adsorption capacity, and increase the specific surface area , to avoid negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 50g chitosan and dissolve in 0.1M acetic acid solution to make 1wt% chitosan acetic acid solution, add 5g glucose and stir to dissolve, add 10g nanometer SiO 2 Powder, ultrasonically dispersed for 5min, then stirred until evenly dispersed, then slowly added 1mol / L NaHCO dropwise while stirring 3 The pH value of the solution was 6.4, and then vigorously stirred for 5 minutes after the dropwise addition, and then placed in a constant temperature water bath at 45°C for 1 hour to obtain a hydrogel, cut the hydrogel into pieces and soaked in deionized water for 12 hours and every 3 hours Change the water once, and finally freeze-dry for 24 hours to obtain glucose cross-linked nano-SiO 2 - Chitosan composite airgel, the gel is white and fluffy. The gel is crushed and sieved to obtain 20-40 mesh gel particles.

Embodiment 2

[0030] Weigh 50g chitosan and dissolve in 0.1M acetic acid solution to make 1wt% chitosan acetic acid solution, add 5g glucose and stir to dissolve, add 20g nanometer SiO 2 Powder, ultrasonically dispersed for 10min, then stirred until evenly dispersed, then slowly added 1mol / L NaHCO dropwise while stirring 3 The pH value of the solution was 6.4, and then vigorously stirred for 5 minutes after the dropwise addition, and then placed in a constant temperature water bath at 45°C for 1 hour to obtain a hydrogel, cut the hydrogel into pieces and soaked in deionized water for 12 hours and every 3 hours Change the water once, and finally freeze-dry for 24 hours to obtain glucose cross-linked nano-SiO 2 - Chitosan composite airgel, the gel is white and fluffy. The gel is crushed and sieved to obtain 20-40 mesh gel particles.

Embodiment 3

[0032]Weigh 50g chitosan and dissolve in 0.1M acetic acid solution to make 1wt% chitosan acetic acid solution, add 5g glucose and stir to dissolve, add 40g nanometer SiO 2 Powder, ultrasonically dispersed for 15 minutes, then stirred until uniformly dispersed, then slowly added 1mol / L NaHCO dropwise while stirring 3 The pH value of the solution was 6.4, and then vigorously stirred for 5 minutes after the dropwise addition, and then placed in a constant temperature water bath at 45°C for 1 hour to obtain a hydrogel, cut the hydrogel into pieces and soaked in deionized water for 12 hours and every 3 hours Change the water once, and finally freeze-dry for 24 hours to obtain glucose cross-linked nano-SiO 2 - Chitosan composite airgel, the gel is white and fluffy. The gel is crushed and sieved to obtain 20-40 mesh gel particles.

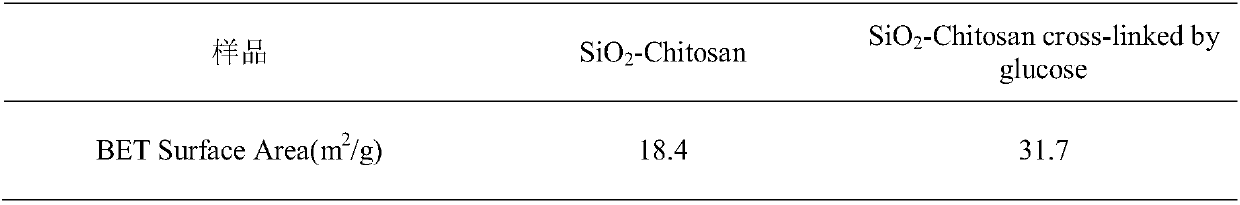

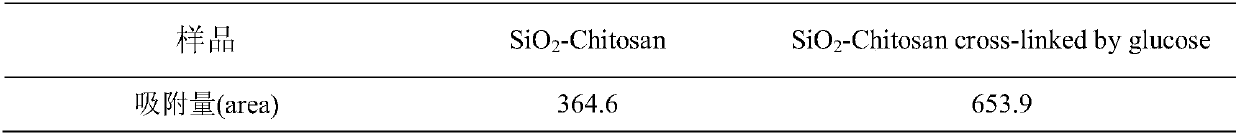

[0033] Simultaneously, the nano SiO that does not add glucose (glucose) is prepared by utilizing above-mentioned embodiment method 2 -Chitosan gel. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com