A method for controlling sulfide inclusions in non-quenched and tempered steel treated with barium alloy

A technology of non-quenched and tempered steel and control method, which is applied in the field of iron and steel metallurgy, which can solve the problems of low control level, prone to nozzle nodules, and high S content, and achieve the effect of preventing nozzle nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Steel type: C70S6BY

[0038] 2) Process flow: 100-ton converter smelting→LF refining+VD vacuum degassing→continuous casting of 220×280 billet→heat preservation and cleaning→heating in furnace→production of φ70mm material→heat preservation→straightening→peeling→pickling and cleaning→ultrasonic Flaw detection → sampling inspection and analysis. Among them, aluminum is added during the tapping process of the converter, and barium alloy is fed at the end of LF refining. While improving the cleanliness of molten steel, the residual Al 2 o 3 The inclusions are denatured into diffusely distributed oxide inclusion cores. As the basis for the further formation of sulfides with oxides as the core, sulfides are added after VD vacuum degassing.

[0039] 3) Key points of process control

[0040] (1) Alloying of converter tapping deoxidizer

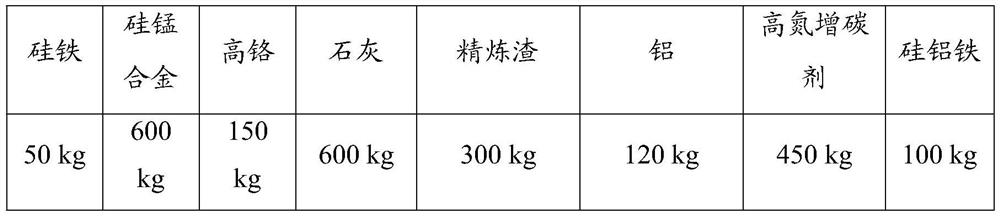

[0041] Aluminum is added in the process of converter tapping for pre-deoxidation operation. The specific adding sequence is: ferrosilico...

Embodiment 2

[0056] 1) Steel type: F45MnV

[0057] 2) Process flow: 70 tons of EAF converter smelting→LF refining+VD vacuum degassing→continuous casting of 180×240 billet→slow cooling / hot delivery→heating furnace heating→product material→slow cooling→straightening→finishing→ultrasonic flaw detection → Check storage. Among them, aluminum is added during the tapping process of the converter, and barium alloy is fed at the end of LF refining. While improving the cleanliness of molten steel, the residual Al 2 o 3 The denaturation of inclusions is a diffusely distributed oxide inclusion core. As the basis for the further formation of sulfides with oxides as the core, sulfides are added after adding barium alloy for ≥ 10 minutes.

[0058] 3) Key points of process control

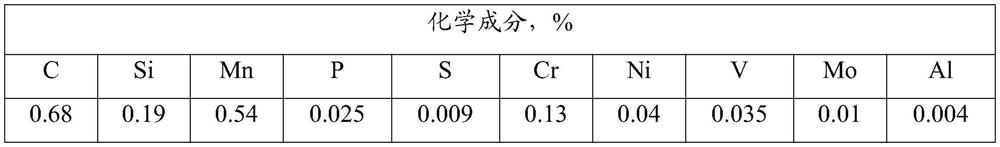

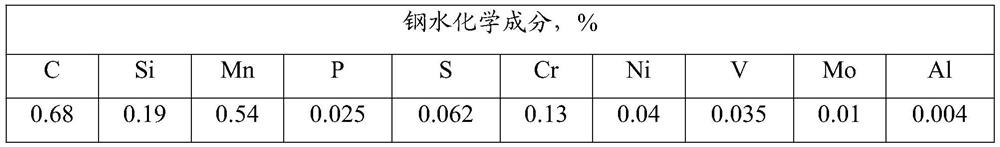

[0059] (1) Pre-deoxidize by adding aluminum in the tapping process of the electric furnace, and adjust the alloy and aluminum content in the refining process as shown in the table below.

[0060]

[0061] (2) Then feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com