Machining method of on-machine detection and correction of small hole of numerical control EDM in turbine blade

A technology for turbine blades and processing methods, which is applied in the field of on-machine detection and correction of turbine blade CNC EDM small holes, can solve the problems of large processing errors of upper gas film holes, achieve high position and angle accuracy, scientific and reasonable thinking, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

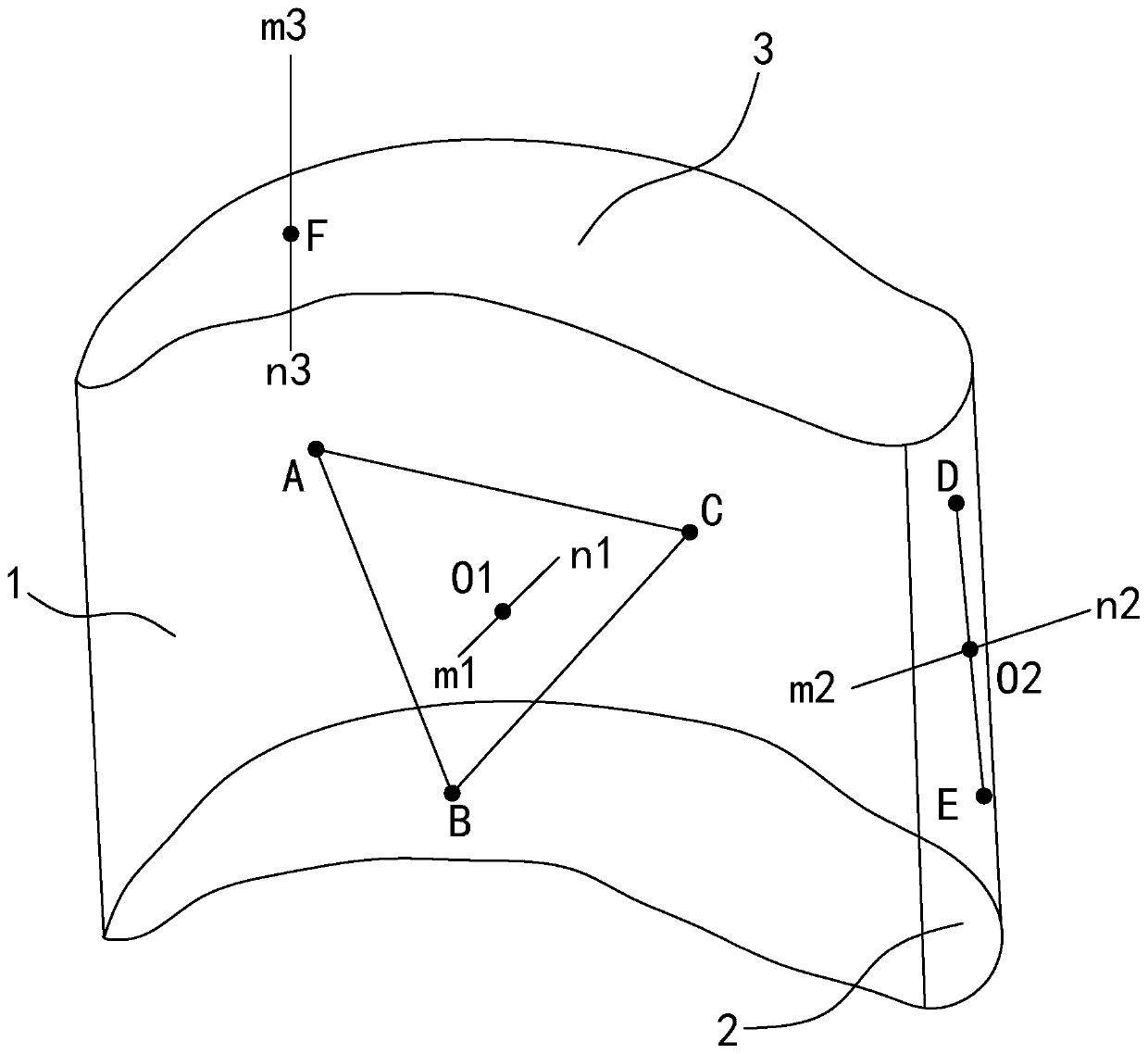

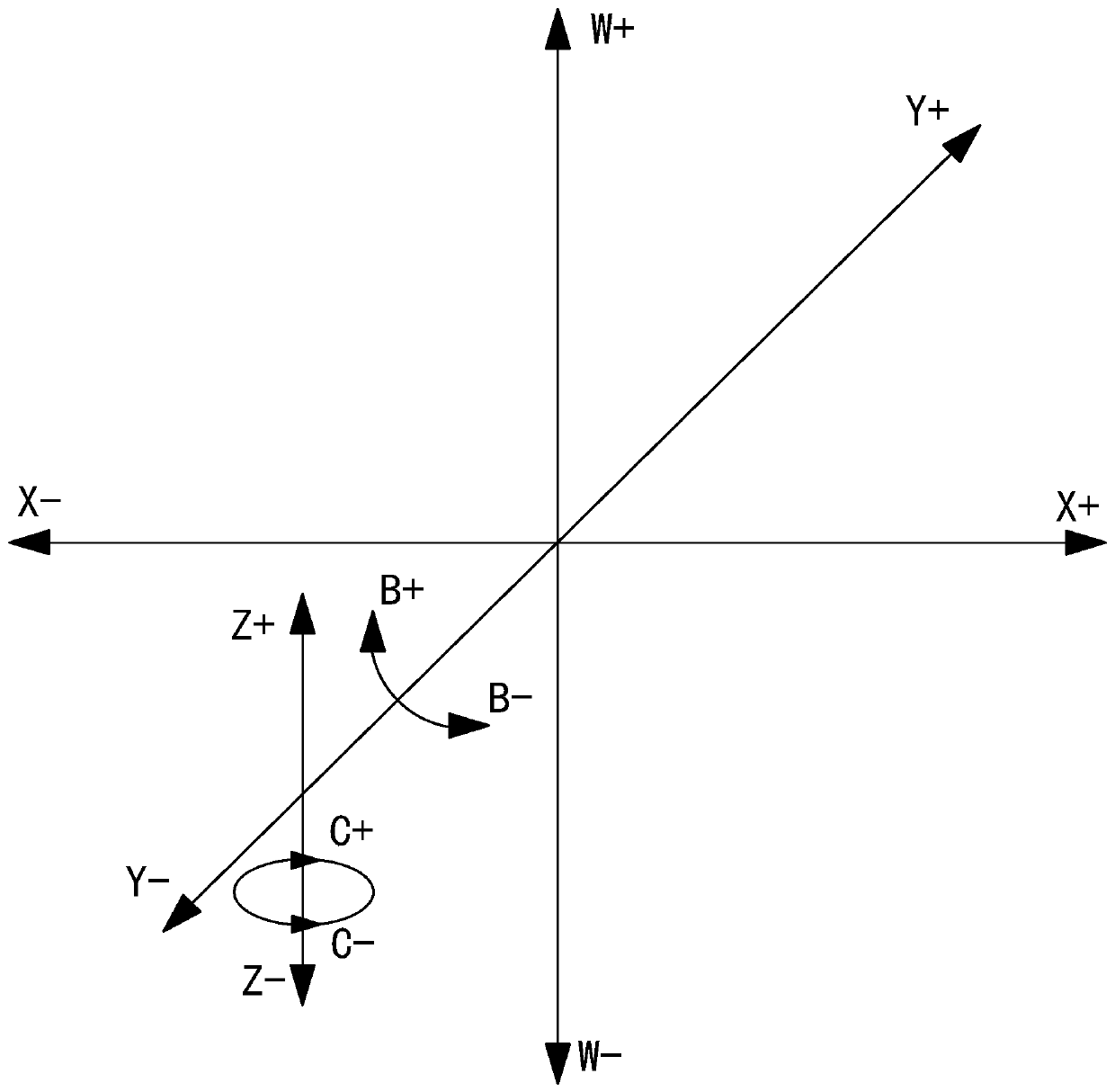

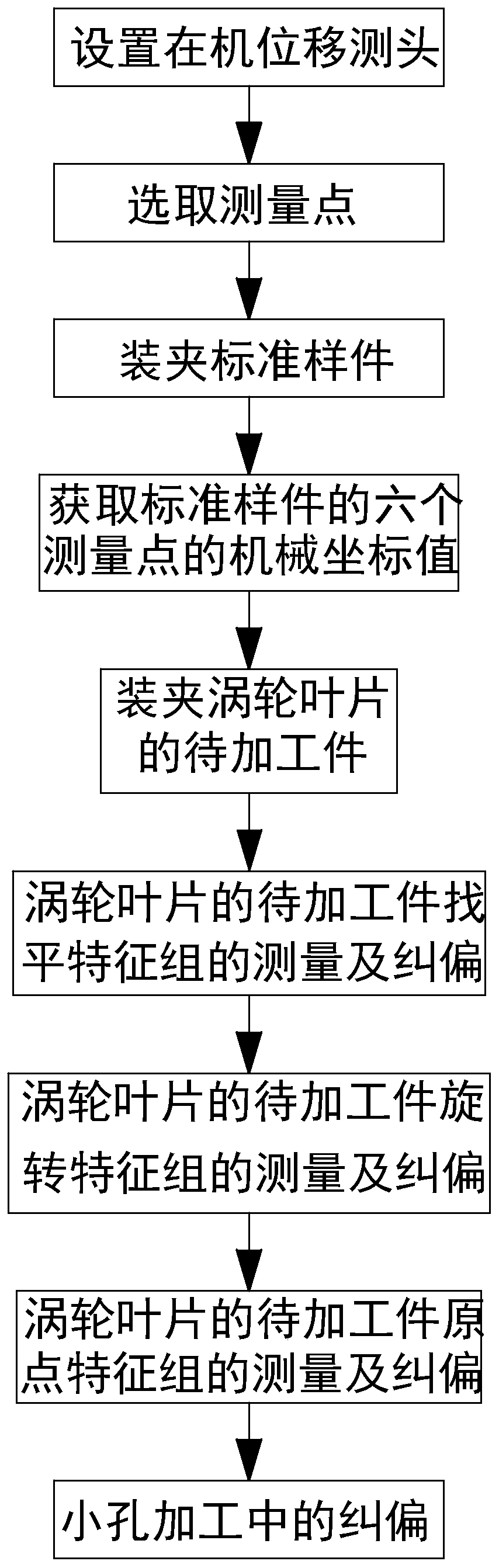

[0050] see Figure 1~Figure 3 As shown, a machining method for on-machine detection and correction of numerical control EDM small holes of turbine blades, the EDM small hole machining machine used in the machining method is equipped with at least six numerical control axes, including four linear axes and two rotary axes axis, the linear axes are X axis, Y axis, Z axis and W axis, and the rotation axes are B axis and C axis.

[0051] (1) Set the displacement measuring head on the machine

[0052] For small hole EDM machine tools, an on-machine displacement probe is set in advance. The on-machine displacement probe is composed of a measuring rod and a displacement sensor at the end of the measuring rod. The on-machine displacement measuring head is installed on the W-axis, and the W-axis Driving up and down movement, the output signal of the displacement sensor is transmitted to the signal input port of the numerical control system of the electric discharge small hole machining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com