Condom delivery mechanism of automatic electric inspection machine condom

A condom and condom delivery technology, which is applied in the direction of male contraceptives, application of electrical devices to test fluid tightness, etc., can solve the problems of unsuitable for high-efficiency delivery of condoms, unreasonable structure, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

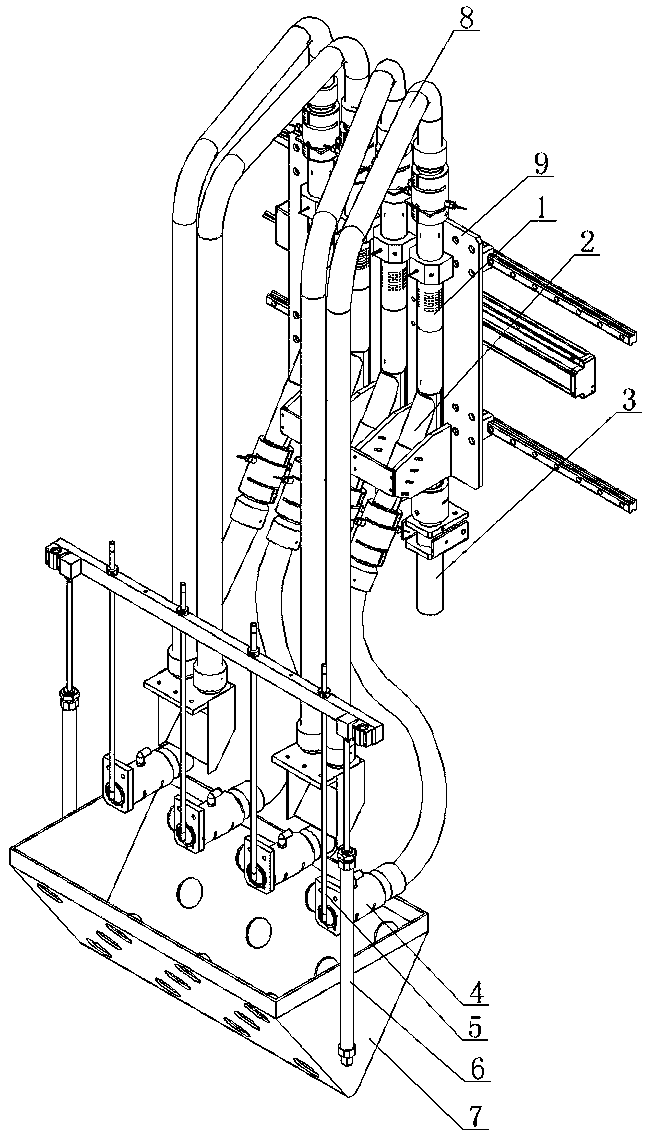

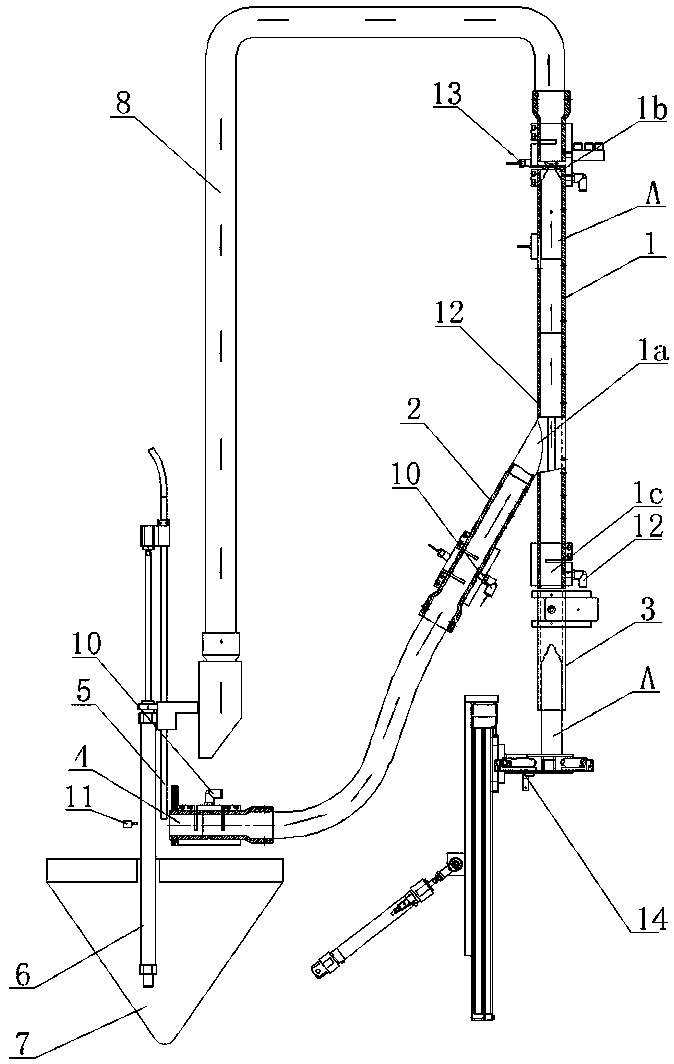

[0015] As shown in the figure, the condom automatic electric inspection machine of the present invention includes a condom-feeding mechanism, which includes a vertical tube 1 and a suction tube 2, and the vertical tube 1 has a tube that matches the outer diameter of the condom A. Holes, the side of the vertical pipe 1 is provided with a sleeve inlet 1a, the suction sleeve 2 is connected to the sleeve inlet 1a, the joint of the suction sleeve 2 and the sleeve inlet 1a has a downward slope design, the suction sleeve 2 An inlet is provided to extract the condom, the inlet end 4 of the suction sleeve is fixedly arranged, and an air blowing nozzle 11 is arranged on the outside of the inlet end 4 of the suction sleeve, and a vacuum suction sleeve rod 5 is arranged between the two, and the vacuum suction sleeve rod 5 is arranged between the two. The sleeve rod 5 is pushed up and down by the lifting part 6. When the vacuum sleeve rod 5 is at the bottom position, it will suck the condom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com