Efficient feed device applied to barley seedling horizontal grinder

A technology of a feeding device and a pulverizer, which is applied in the direction of grain processing, etc., can solve the problems of clogging, reducing the processing efficiency of barley leaf crushing, and the feeding can not keep up, so as to achieve precise feeding action, improve the processing efficiency of crushing, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

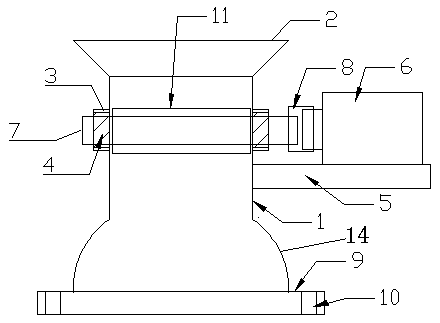

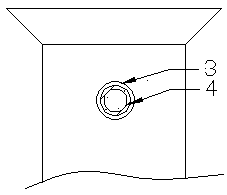

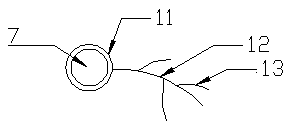

[0017] Such as figure 1 , figure 2 and image 3 The shown high-efficiency feeding device applied to the barley grass horizontal pulverizer includes a vertical rectangular hollow box 1, an inverted conical hollow feed port 2 arranged at one end of the vertical rectangular hollow box 1, and a set The conical hollow discharge port 14 at the other end of the vertical rectangular hollow box body 1, and the circular positioning flange 9 arranged at one end of the conical hollow discharge port 14, and the method arranged in the circular positioning flange 9 Lan positioning holes 10, and a group of bearing positioning sleeves 3 symmetrically arranged on the outer walls of the two ends of the vertical rectangular hollow box body 1, and bearings 4 respectively arranged in a group of bearing positioning sleeves 3, and the two ends respectively pass through the vertical rectangular The rotating shaft 7 of hollow box, bearing 4, and the axle sleeve 11 that is arranged on the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com