Concrete beam damage monitoring system and monitoring method

A technology for concrete beams and monitoring systems, applied to measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of difficult monitoring work and structural health monitoring, and achieve high power, simple structure, sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

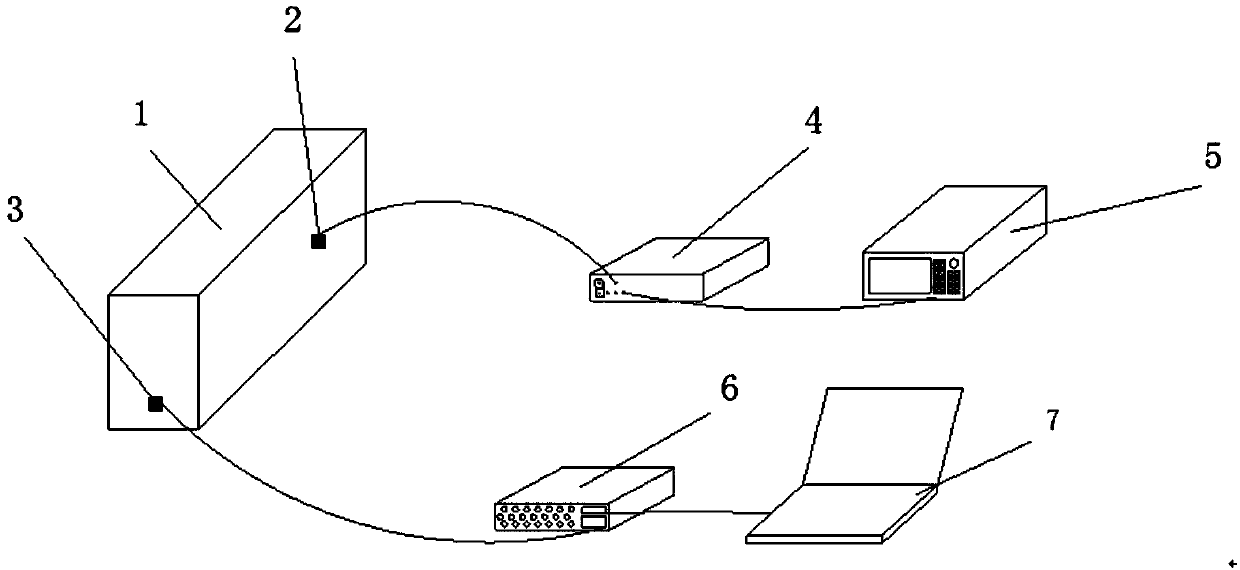

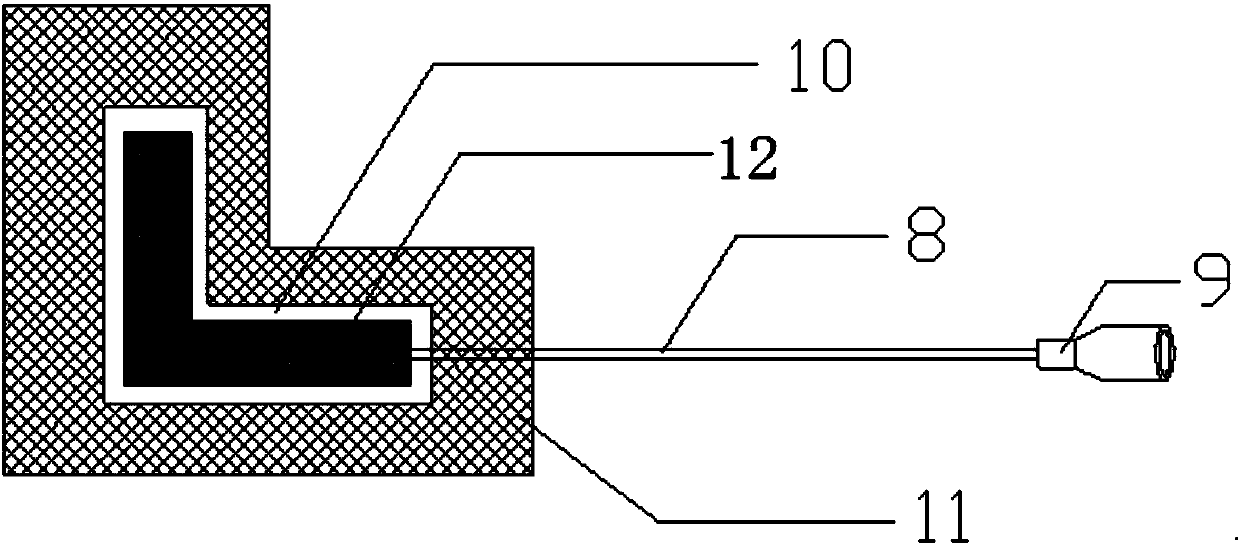

[0092] Such as Figure 4 As shown, the intelligent aggregate is embedded in the key position of the concrete beam. The piezoelectric ceramic sensor is connected to the signal acquisition system through the shielded wire. The signal acquisition system is connected to the computer analysis system. The signal function generator is connected to the piezoelectric ceramic driver through the high voltage signal amplifier. connect,

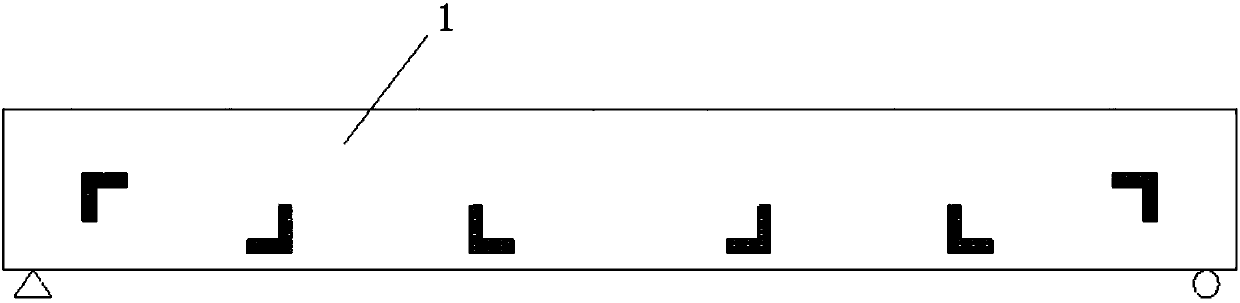

[0093] The cross-sectional size of the concrete beam is 0.2m×0.4m, and the length is 3m. The prefabricated intelligent aggregates SA1, SA2, SA3, SA4, SA5, and SA6 are embedded in the concrete beam in order from left to right. method effectiveness, before pouring concrete, a thin foam board was pasted in the cracked area to simulate the damaged area,

[0094] a. The distance between intelligent aggregates is 0.5m, and the distance between intelligent aggregate SA1 and intelligent aggregate SA6 is 0.25m from the end face of the concrete beam. The sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com