A Calculation Method of Feature Points of Curved Reinforcement Cage

A calculation method and steel cage technology, applied in design optimization/simulation, geometric CAD, CAD numerical modeling, etc., can solve the problem that it is difficult to determine the relative position of the binding operation platform and the steel cage in advance, it is difficult to connect the steel cage, and it is difficult to connect each section. segment positioning and other issues, to achieve the effect of fast point placement on site, avoiding low efficiency, and good splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

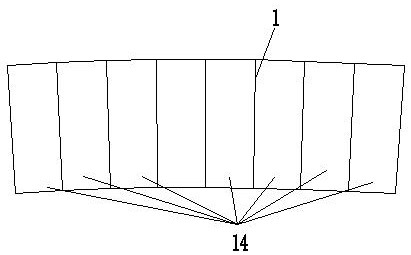

[0064] This embodiment is applied to the occasion of determining the characteristic points of the steel cage in the curved section.

[0065] Such as image 3 with Figure 4 As shown, the calculation method of the characteristic points of the steel cage in the curve segment includes the following steps:

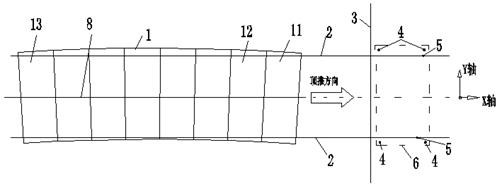

[0066] a, establish a coordinate system, set up the planar Cartesian coordinate system of the immersed tube reinforcement cage binding platform 6 and the jacking system in the drawing software, and the jacking system in the present embodiment is the jacking girder 3;

[0067] b, arrange reference control points, set a plurality of reference control points 4 on the site binding platform, and mark a plurality of reference control points 4 on the binding platform 6, so that the position coordinates of the reference control points 4 are fixed;

[0068] c. Arrange the push track control point 5, arrange the push track control point 5 on the site binding platform 6, and arrange th...

Embodiment 2

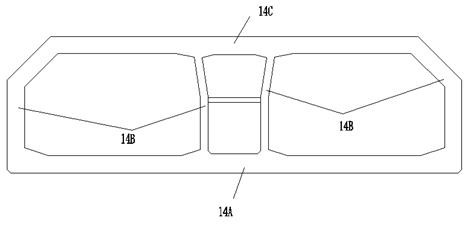

[0084] This embodiment illustrates the process of using the method in Embodiment 1 to determine the feature points of the curved segment reinforcement cage wall segment.

[0085] Such as Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, when the wall section 14B of the curved section immersed pipe 1 is bound, the process of determining the feature points specifically includes the following steps:

[0086] Step 1.1, drawing, draw the wall section binding platform 6, the wall back frame 7 and the pushing girder 3 for pushing the reinforcement cage in the coordinate system, the coordinate system adopts the coordinates established in step a in embodiment 1 system, the wall back frame 7 is an operating platform for binding the steel cage of the wall section, and the position of the pushing girder 3 is the position before pushing;

[0087] Step 1.2, on-site jacking, jacking the floor reinforcement cage to the pre-marked jacking stop mark line, and measuring the jacking l...

Embodiment 3

[0098] This embodiment illustrates the calculation process for determining the characteristic points of the roof section of the immersed tube in the curved section and the position of the chamfering template of the roof section.

[0099] Adopt the calculation method identical with embodiment 1 or embodiment 2 to determine the feature point of the roof section, and complete on-the-spot setting point according to this feature point, carry out binding, specifically comprise the following steps:

[0100] Step 2.1, drawing, draw the roof section binding platform, the roof binding support frame and the pushing girder for pushing the steel cage in the coordinate system, which is the coordinate system established in step a in embodiment 1, the roof The position of the push girder is the position before the push;

[0101] Step 2.2, on-site jacking, push the wall reinforcement cage to the pre-marked jacking stop mark line, and measure the jacking length of the jacking girder;

[0102] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com