Impact starting method and system for brushless direct current motor of electric tool

A brushless DC motor and power tool technology, applied in the field of impact starting method and system of a brushless DC motor for power tools, can solve the problems of increased manufacturing cost, large heat generation of motor windings, and enlarged product volume, etc. The effect of reliable use without increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

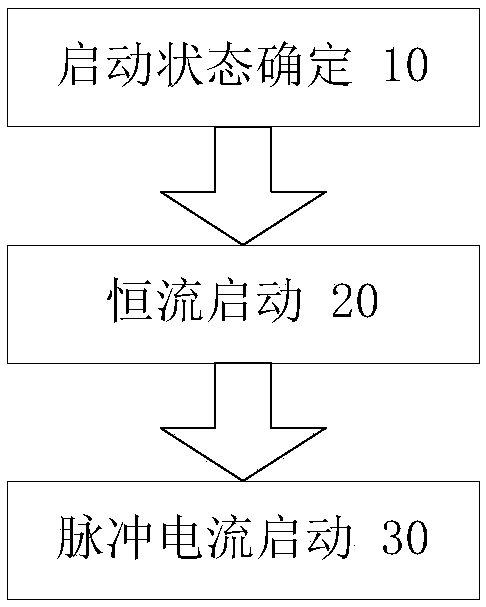

[0028] Such as figure 1 Shown, the present invention a kind of electric tool brushless DC motor impact starting method, comprises the following steps:

[0029] (10) Starting state determination: According to the motor speed during the starting process, it is judged that the starting working state area of the motor is a normal starting state or a locked-rotor state;

[0030] When the speed of the motor is lower than 1000rpm, it is determined that the motor is in a stalled state.

[0031] When the motor speed reaches 1000rpm and above, it is determined that the motor is in a normal startup state.

[0032] The working state is judged by whether the speed or position of the motor rotor changes: if the speed is too low or the position hardly changes, it is judged to be in a stalled state; otherwise, if the speed rises normally or reaches a stable state, it is judged to be in a normal working state.

[0033] In the (10) state determination step, when the measured motor rotor spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com