Automatic smoke gas purifying device

An automatic purification and flue gas technology, applied in chemical instruments and methods, mixers, fluid mixers, etc., can solve problems such as low precision, poor purification effect, and uneven purification reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

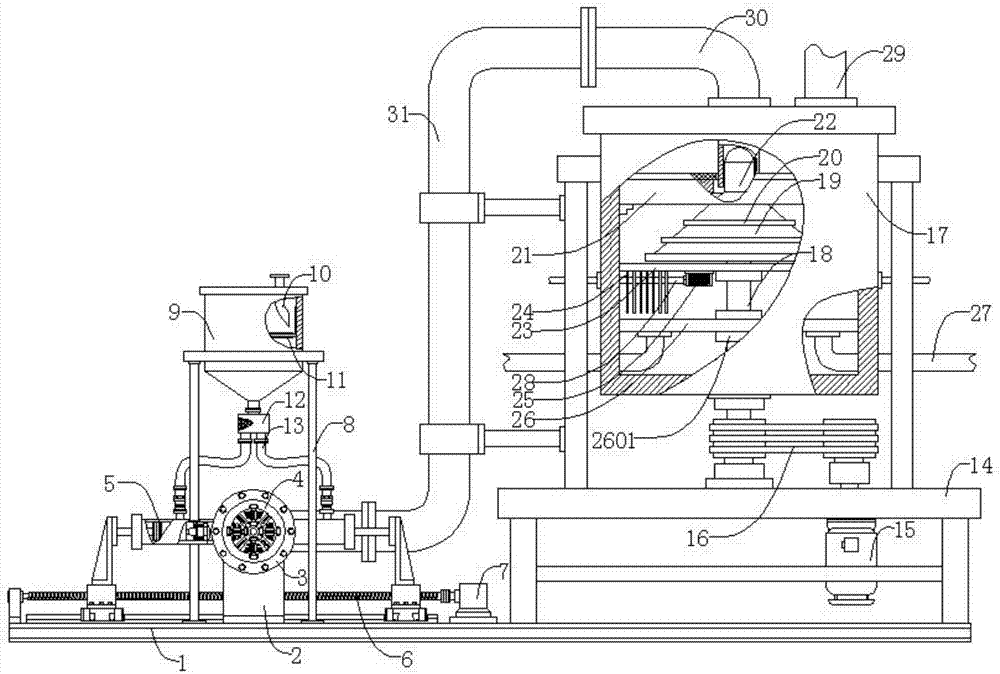

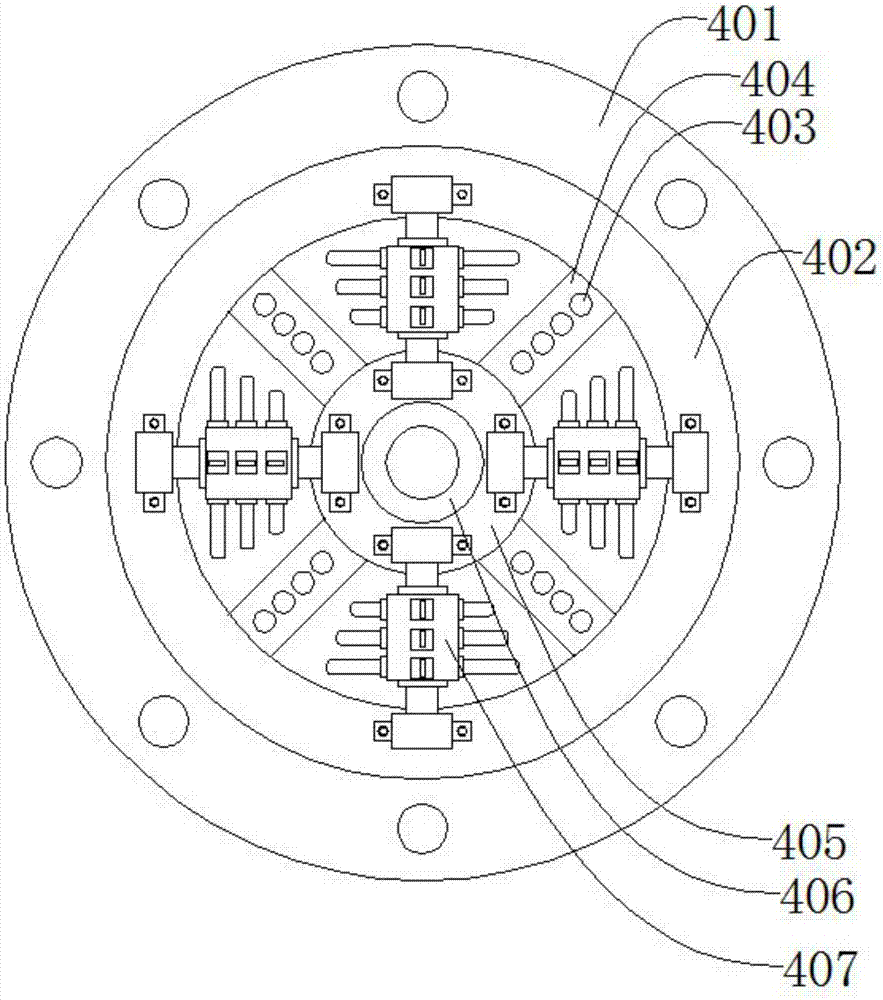

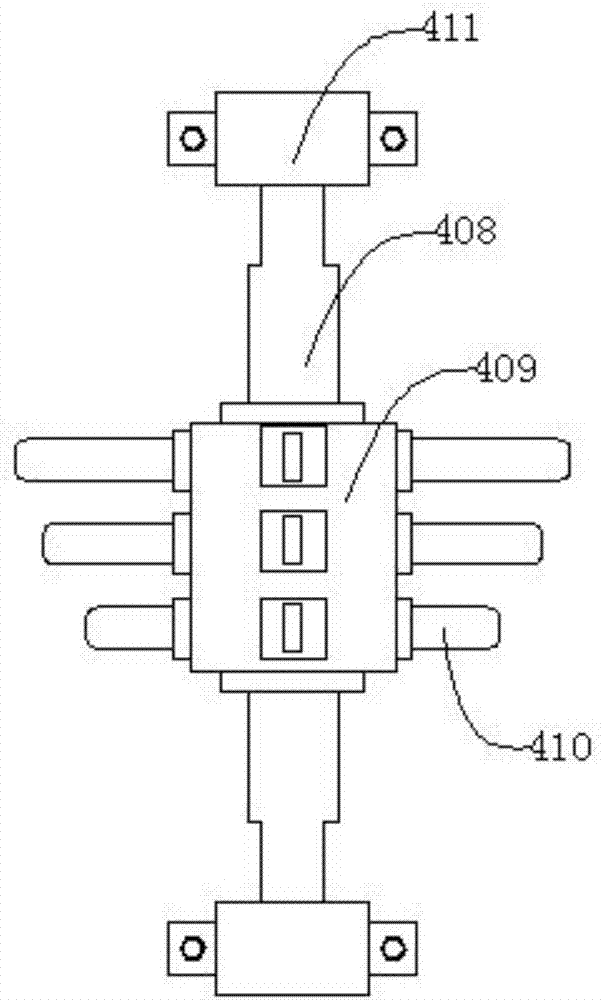

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, an automatic flue gas purification device includes a base 1, a bracket 2, a water inlet pipe 3, a dispensing mechanism 4, a pumping mechanism 5 symmetrically arranged in two pieces along the dispensing mechanism 4, a lead screw 6, a servo Motor 7, first support 8, medicine tank 9, liquid medicine inlet pipe 10, filter screen 11, shunt box 12, shunt pipe 13, the second support 14, speed regulation Motor 15, transmission mechanism 16, purification tank 17, first rotating shaft 18, conical head 19, spinner 20 whose diameters are uniformly distributed from top to bottom along the conical head 19 and whose number is no less than 2 pieces, and which are equipped with Air plate 21, deflector head 22, upper partition 23, intubation pipe 24, gas collection box 25, lower partition 26, sewage pipe 27, clean gas outlet pipe 28, flue gas inlet pipe 29, liquid inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com