Flying shear controlling system and method

A flying shear control and control unit technology, applied in the field of flying shear control system, can solve the problems of poor control performance, slow operation speed and high overall cost, and achieve the effect of improving performance and smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

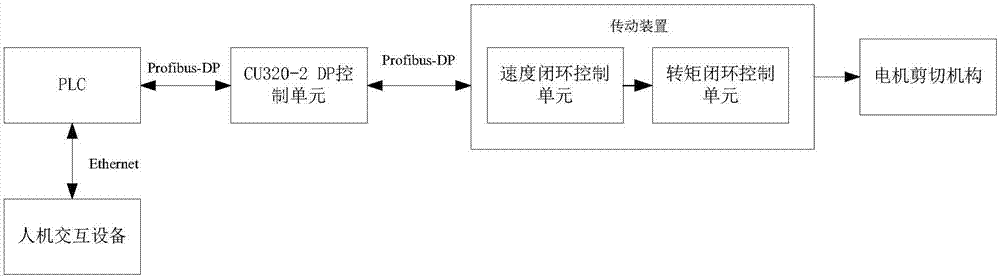

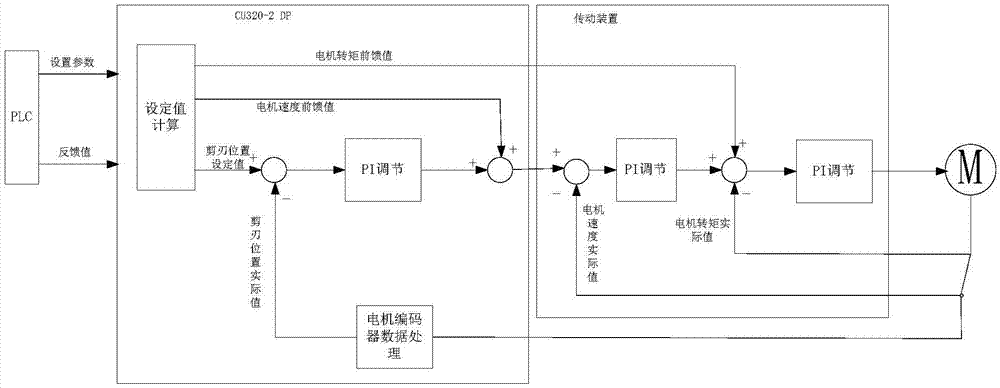

[0048] This embodiment discloses a flying shear control system, such as figure 1 As shown, including PLC and CU320-2DP control unit as the position closed-loop control unit;

[0049] In this embodiment, the PLC is connected to the CU320-2DP control unit to generate the target position value of the cutting blade, the maximum speed value of the cutting blade and the maximum acceleration value of the cutting blade, and send them to the CU320-2DP control unit. In this embodiment, the PLC can Send the above data to the CU320-2DP control unit through the Profibus-DP bus; the PLC provides a man-machine interface for the operator to set parameters. In this embodiment, the operator can set the relevant parameters such as the cutting length in the PLC through the man-machine interface The PLC in the flying shear control system of the present embodiment is connected to the rolling line control system, obtains the speed value of the upstream rolling mill and the speed value of the downstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com