Laser-arc hybrid welding process

A laser arc and hybrid welding technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low gap and low steel plate thickness, and achieve the effect of increasing penetration and excellent forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The thickness of the welding plate is 10mm, and the gap between the welding plates is 5mm.

[0032] The laser power is 8 kilowatts, the defocus is 2-4mm, and the spot diameter is 4-7mm.

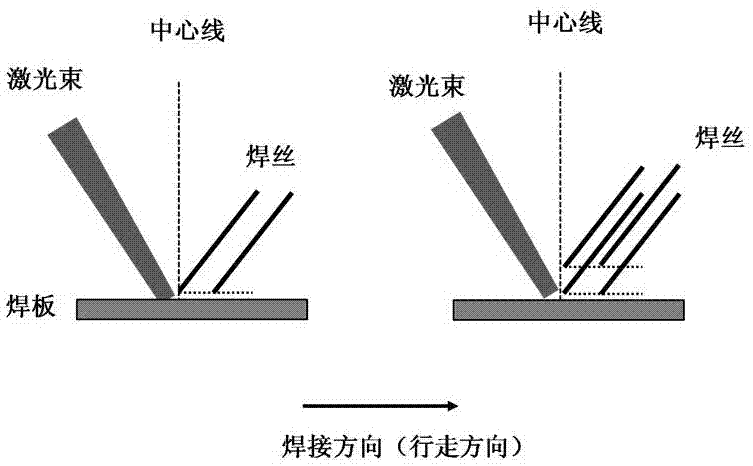

[0033] The inclination angle between the welding wire and the welding plate is 48°; the diameter of the first group of welding wires is 1.2mm, and the distance between the welding wires is 2mm; the current of the first group of welding wires is 160-180A.

[0034] The oscillation frequency of the laser beam and electric arc is 30 Hz, and the oscillation amplitude is 3 mm.

[0035] Lay a layer of metal powder under the welding wire, the thickness of the powder layer is 2mm.

[0036] The welding speed is 1.4m / min.

[0037] Inspection results: full penetration, no undercut, well-formed welds, and no defects.

Embodiment 2

[0039] The thickness of the welding plate is 20mm, and the gap between the welding plates is 8mm.

[0040] The laser power is 18 kilowatts, the defocus is 3-7mm, and the spot diameter is 5-10mm.

[0041] The inclination angle between the welding wire and the welding plate is 55°, the diameter of the first group of welding wires is 1.6mm, and the distance between welding wires is 3.5mm; the diameter of the second group of welding wires is 2.4mm, and the distance between welding wires is 5.0mm; The energizing current of the two sets of welding wires is 160-220A.

[0042] The oscillation frequency of the laser beam and electric arc is 16 Hz, and the oscillation amplitude is 6 mm.

[0043] Lay a layer of metal powder under the welding wire, the thickness of the powder layer is 5mm.

[0044] The welding speed is 0.9m / min.

[0045] Inspection results: full penetration, no undercut, well-formed welds, and no defects.

Embodiment 3

[0047] The thickness of the welding plate is 16mm, and the gap between the welding plates is 6mm.

[0048] The laser power is 15 kilowatts, the defocus is 3-6mm, and the spot diameter is 5-8mm.

[0049] The inclination angle between the welding wire and the welding plate is 53°; the diameter of the first group of welding wires is 1.6mm, and the distance between welding wires is 3.2mm; the diameter of the second group of welding wires is 2.0m, and the distance between welding wires is 4.8mm; The energizing current of the two sets of welding wires is 150-180A.

[0050] The oscillation frequency of the laser beam and electric arc is 22 Hz, and the oscillation amplitude is 5 mm.

[0051] Lay a layer of metal powder under the welding wire, the thickness of the powder layer is 4mm.

[0052] The welding speed is 1.0m / min.

[0053] Inspection results: full penetration, no undercut, well-formed welds, and no defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com