Automatic welding equipment applied to furniture production line

An automatic welding and production line technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not having a good buffer for vibration, reducing the service life of the equipment, and affecting the performance of the equipment, so as to achieve good reduction Shock effect, protection equipment, work stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

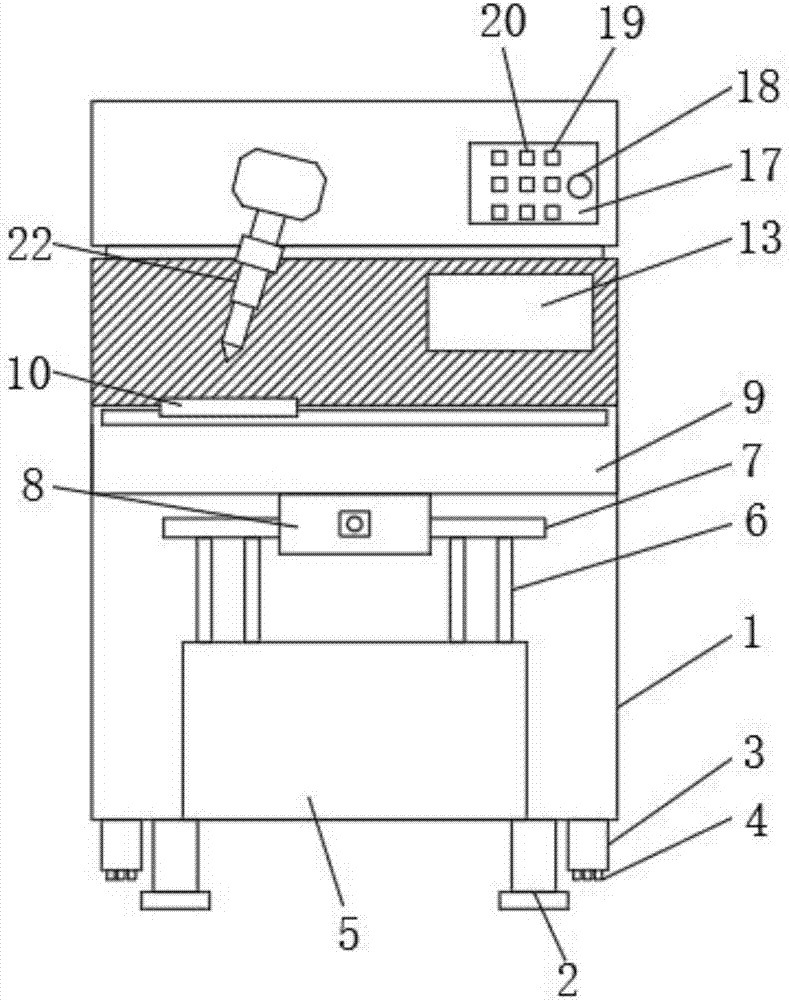

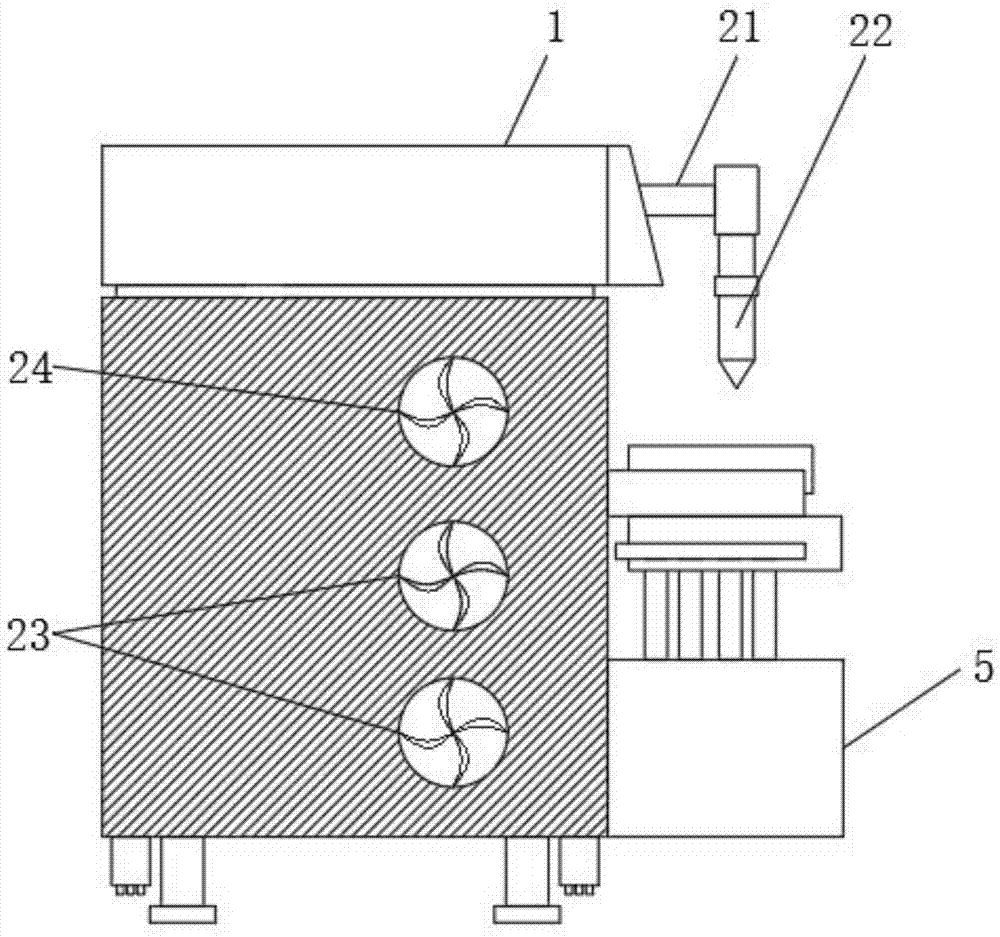

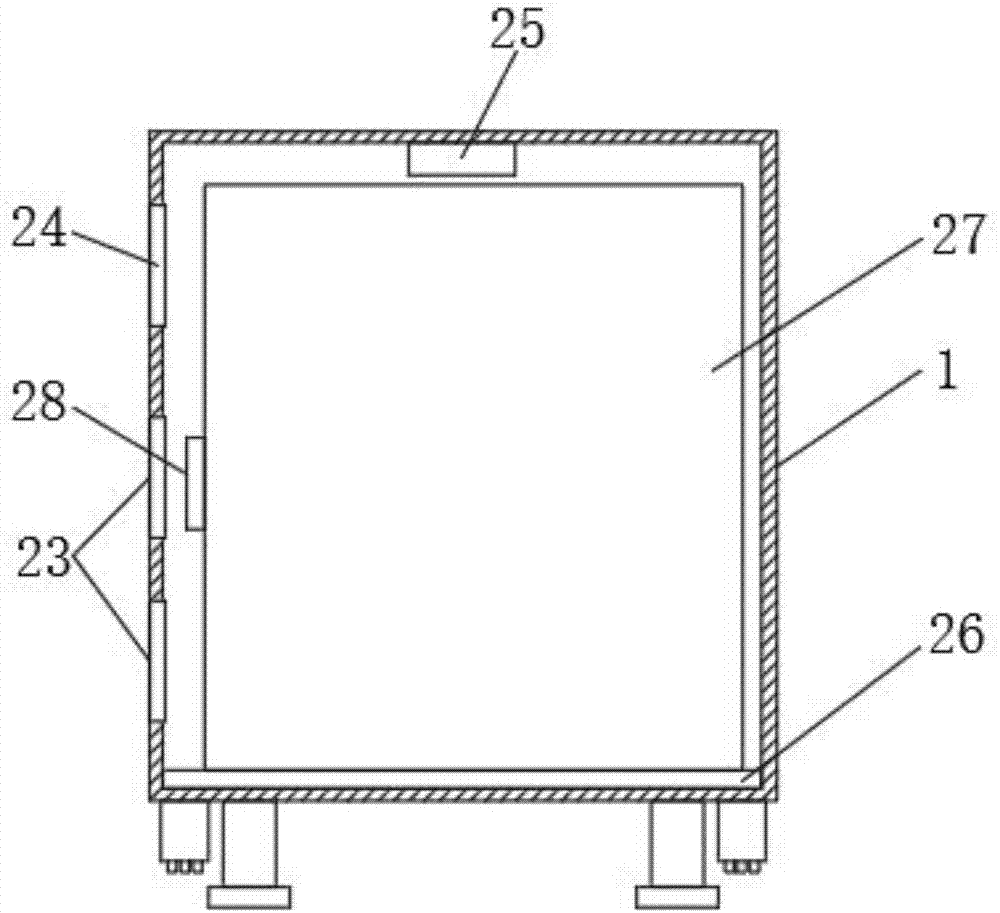

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] see Figure 1-5 , the present invention provides a technical solution: an automatic welding equipment applied to a furniture production line, including a chassis 1, a leg 2, an electro-hydraulic rod 3, a pulley 4, a hydraulic box 5, a hydraulic column 6, a connecting plate 7, a fastening Block 8, vertical moving platform 9, horizontal moving workbench 10, groove 11, hinge 12, groove cover 13, universal pipe 14, lighting 15, battery 16, control panel 17, power switch 18, electric hydraulic lever switch 19. Light switch 20, rotating shaft 21, welding head 22, first cooling fan 23, second cooling fan 24, temperature sensor 25, shock absorber 26, welding applianc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com