Clamping unit

A clamping element and clamping technology, used in clamping devices, clamping, clamps, etc., can solve the problems of hydraulic unit consumption, slow response of switching signals, etc., to achieve cost-effective, fast clamping process, accurate workpiece clamping tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

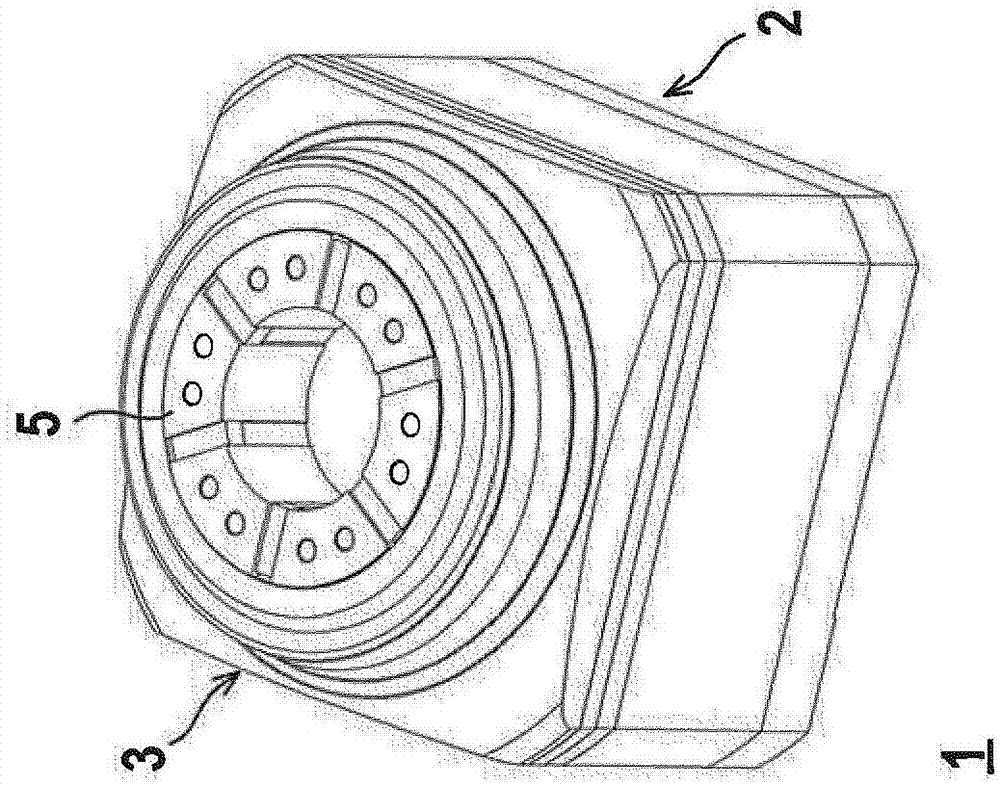

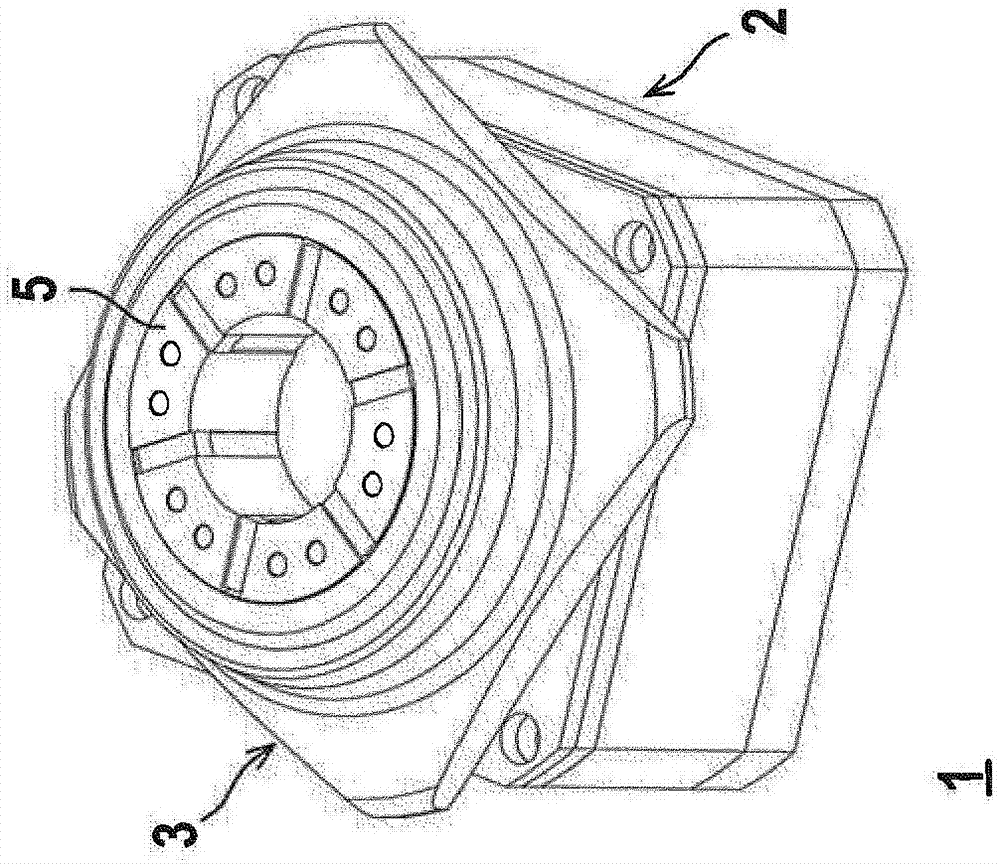

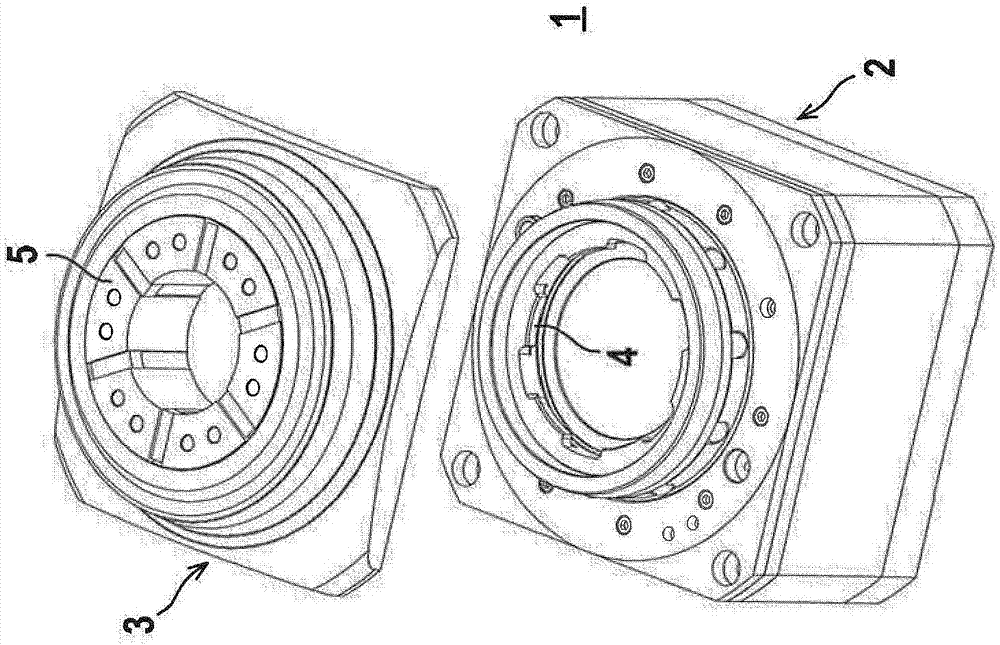

[0049] Figures 1a to 1c as well as figure 2 An exemplary embodiment of a clamping unit 1 for clamping workpieces according to the invention is shown.

[0050] such as especially Figures 1a to 1cAs shown, the clamping unit 1 has a modular design, so that a reversibly releasable fastening of a replacement connection 3 is possible on the base module 2 . The base module 2 here forms a universal module to which different exchange connectors 3 can be fastened. The fastening of the replacement connector 3 to the base module 2 takes place by means of a bayonet lock. exist Figure 1c The locking element 4 of the bayonet lock on the base module 2 can be seen in .

[0051] Each change head 3 generally has a plurality of clamping elements 5 for clamping workpieces. The individual exchange joints 3 are distinguished from one another by the design of the clamping element 5 . exist Figures 1a to 1c In the example shown, the clamping element 5 forms a clamping head for externally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com