Feeding mechanism for spare tire cover plate covered edge processing

A technology of feeding mechanism and spare wheel cover, which is applied in the direction of conveyor objects, thin material handling, transportation and packaging, etc., can solve the problems of unfavorable automatic operation production of enterprises, difficulty in long-term operation, and prone to work errors, etc., to reduce labor Labor intensity, continuous operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

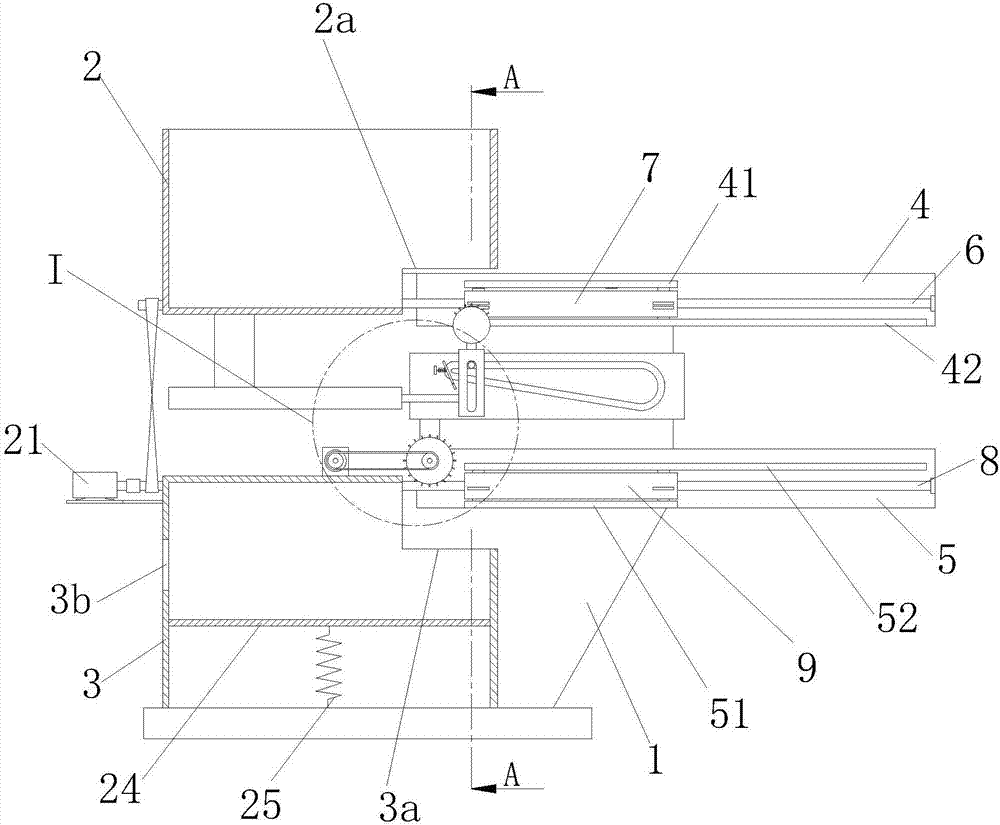

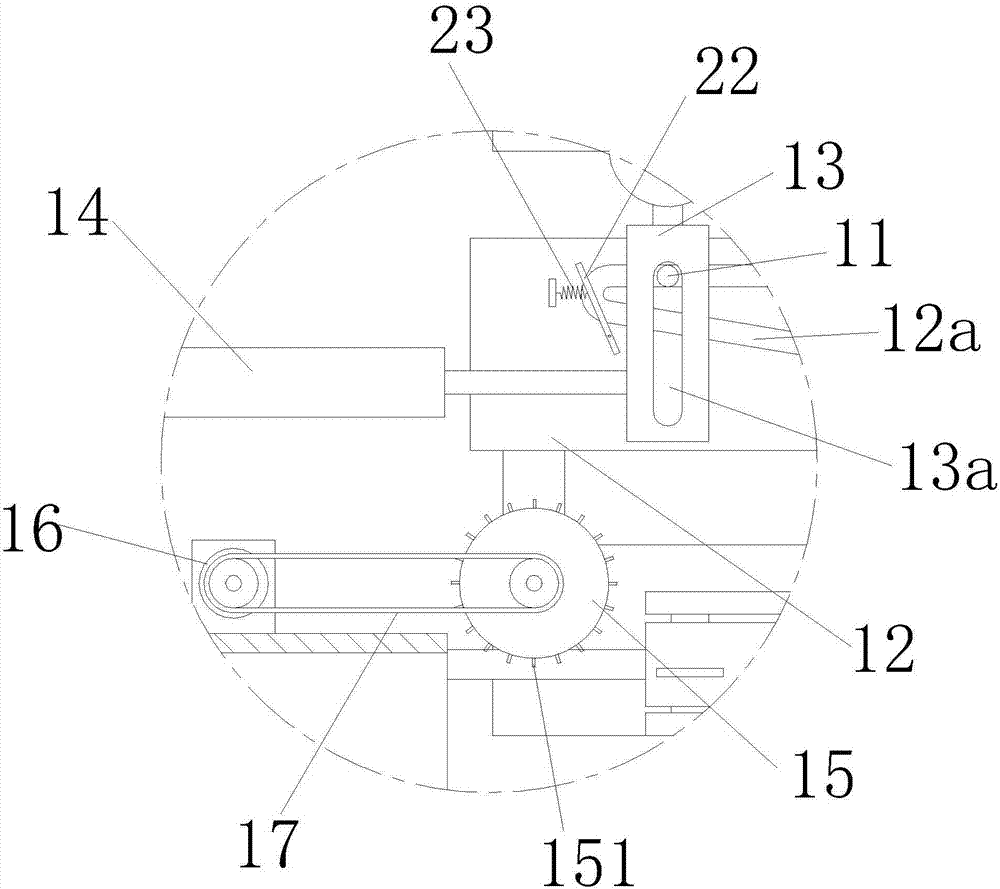

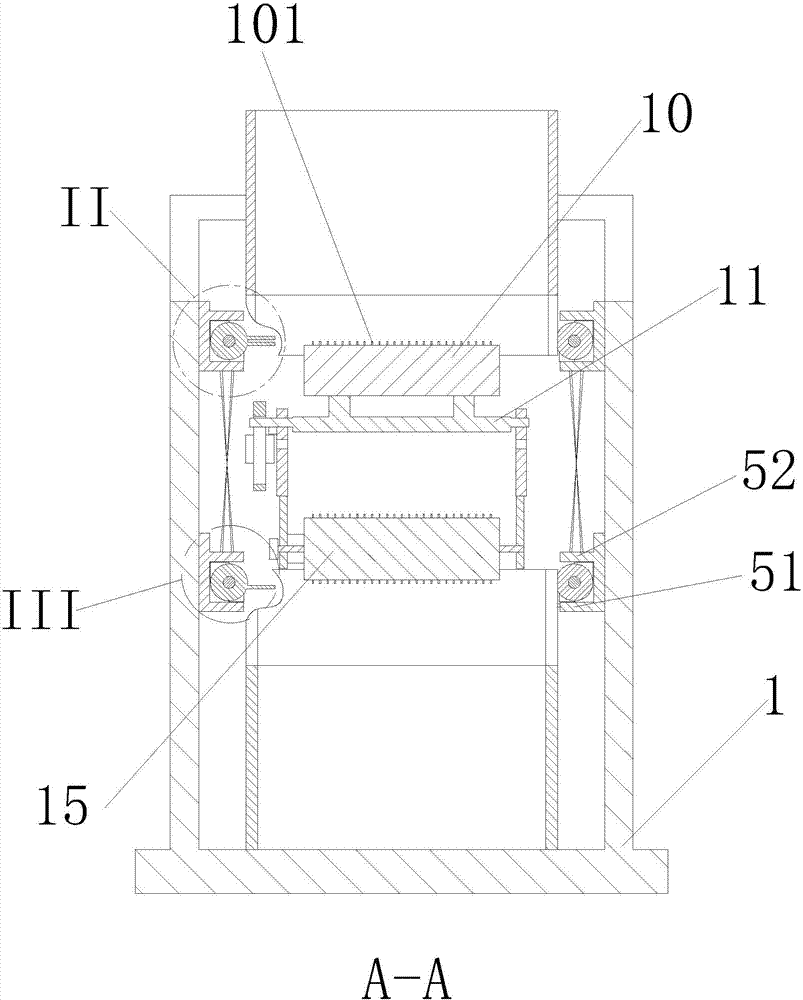

[0028] Such as Figure 1 to Figure 6 As shown, a feeding mechanism for the processing of spare tire cover plate hemming includes a frame 1 on which a fabric box 2 located at the upper end of the frame 1 and a base material box located at the lower end of the frame 1 are fixed. 3. The No. 1 guide plate 4 and the No. 2 guide plate 5 are distributed up and down in the middle of the frame 1. The lower right end of the fabric box 2 is provided with a No. 1 outlet 2a, and the No. 1 outlet 2a is provided with a reciprocating fabric take-off material mechanism, the No. 1 guide plate 4 is provided with a No. 1 transmission mechanism for transporting and lifting the fabric, and the upper right end of the substrate box 3 is provided with a No. 2 outlet 3a, and the No. 2 outlet 3a is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com