a kind of hfs 2 Preparation method of single crystal nanosheet

A single crystal nano, substrate technology, applied in the direction of single crystal growth, single crystal growth, nanotechnology, etc., can solve the problems of limiting HfS research, difficult to control the number of layers, and low yield.

Active Publication Date: 2019-10-01

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above studies are all based on the HfS obtained by the mechanical exfoliation method. 2 , the few-layer HfS obtained by mechanical exfoliation is difficult to control 2 The number of layers, while the yield is very low, greatly limits the ability of HfS 2 Research

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

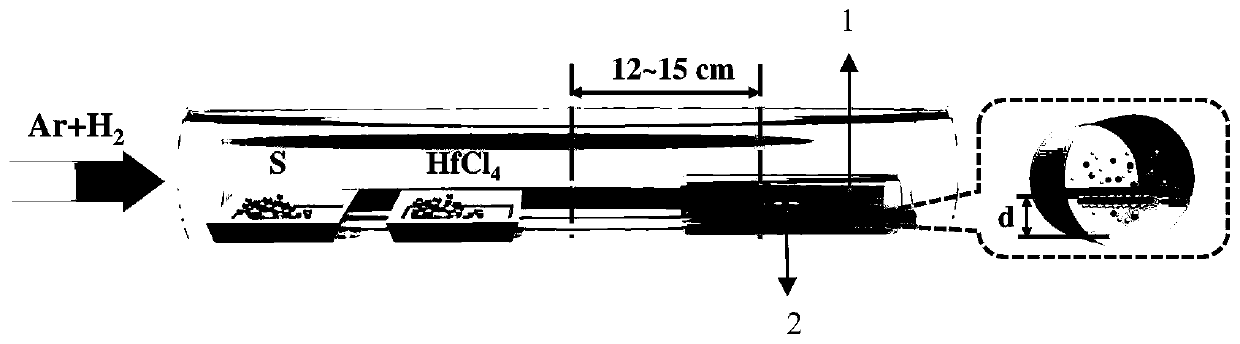

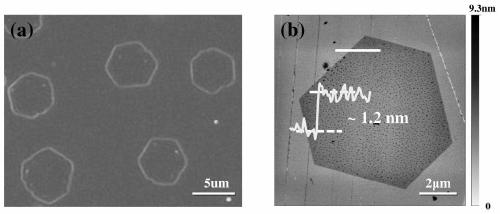

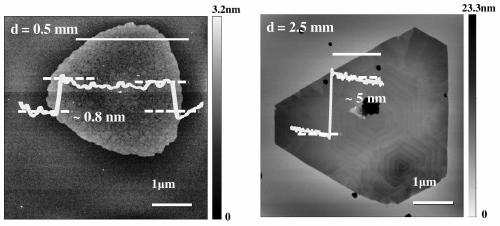

A HfS 2 The invention discloses a method for preparing single crystal nanosheets, belonging to the field of semiconductor material preparation. The method comprises the following steps: 1) placing the S source and the Hf source in the upstream area of the quartz tube, placing the embedded quartz tube with an inner diameter smaller than the quartz tube in the downstream area, and placing the mica substrate in the embedded quartz tube; 2) placing the quartz tube inside the quartz tube Vacuumize, feed inert gas to keep the pressure in the tube at normal pressure, and then feed carrier gas and protective gas; 3) Heat the S source and Hf source to evaporate, at a temperature of 800-980°C, the mica substrate and the embedded quartz Under the condition that the distance d between the lower wall of the tube is 0.5-2.5 mm, react for 5-15 minutes, wait for the quartz tube to cool down to room temperature naturally, and take out the substrate. The present invention realizes the HfS with a thickness of 0.8-15nm and a side length of 5μm by optimizing the distance d between the mica substrate and the lower wall of the embedded quartz tube and the deposition temperature. 2 Controlled growth of nanosheets.

Description

technical field The invention belongs to the technical field of preparation of semiconductor materials, in particular to a HfS 2 Preparation method and application of single crystal nanosheets. Background technique In recent years, ultra-thin two-dimensional materials with atomic-level thickness have received extensive attention, especially transition metal sulfides, because of their unique physical and chemical properties and certain band gaps, they have great significance in the fields of micro-nano electronics and photodetection. application prospects. Two-dimensional materials with high mobility are suitable for various micro-nano electronic devices, and play an important role in promoting the development of the semiconductor device industry. Hf 2 It is a transition metal sulfide of group IVB, and its interlayer forms a layered structure through the extremely weak Van der Waals force, the interlayer distance is about 0.59nm, and each layer is composed of a S-Hf-S san...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C30B25/00C30B29/46C30B29/60B82Y15/00B82Y30/00B82Y40/00

Inventor 熊杰晏超贻邬春阳龚传辉戴丽萍李言荣

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com