Spiral hole way magnetorheological mud damper

A magnetorheological and damper technology, used in shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve problems such as the limitation of magnetorheological mud dampers, improve adjustability, slow down aging, avoid The effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

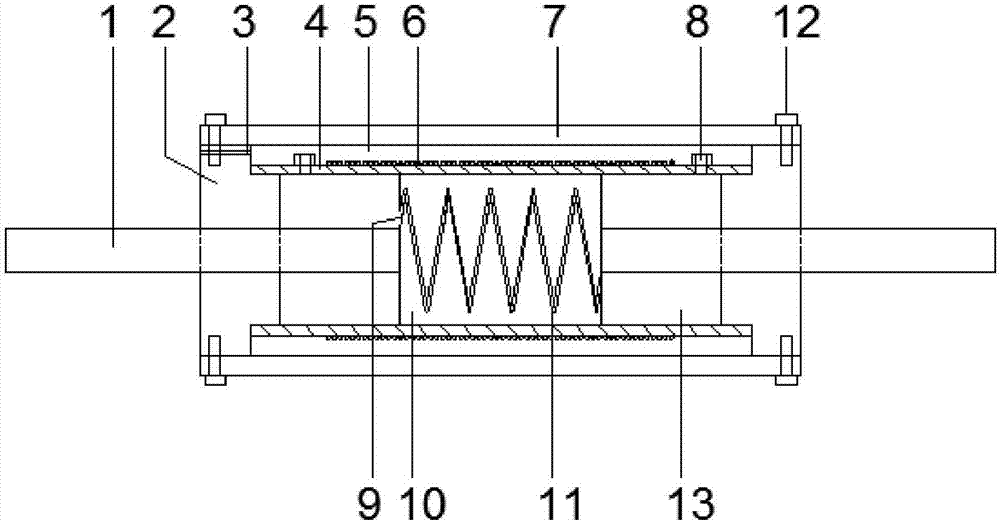

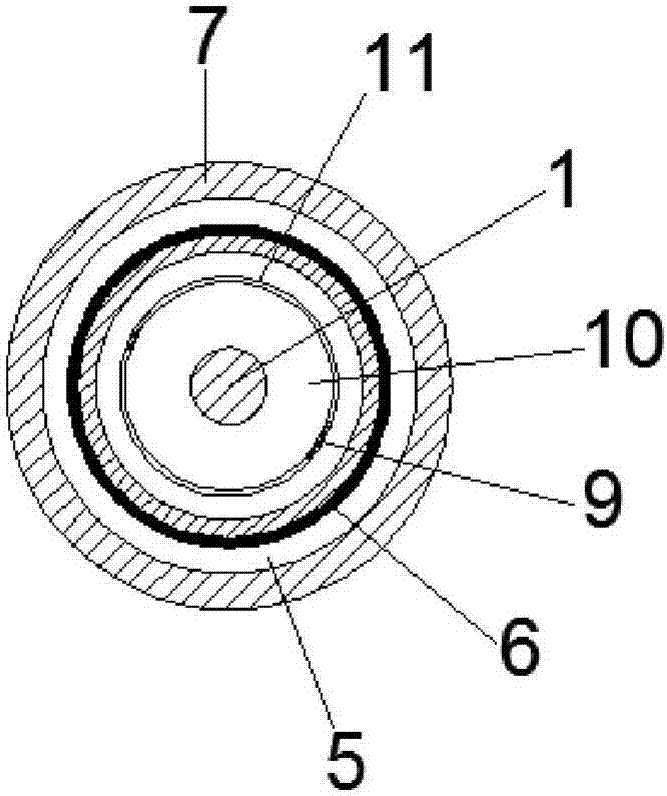

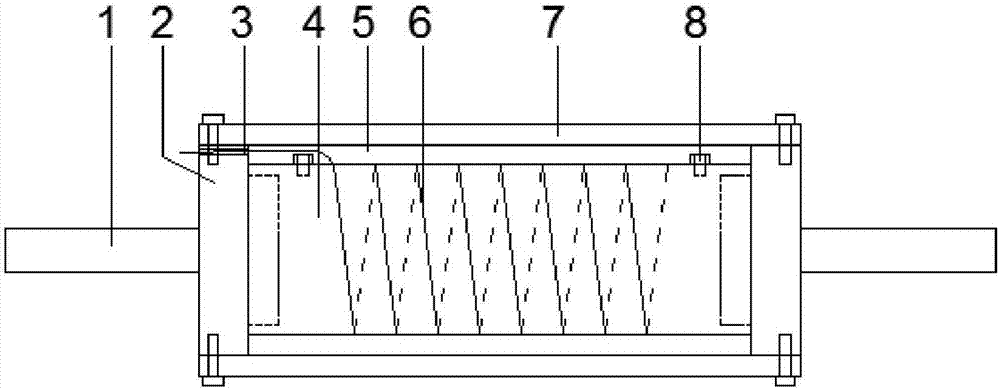

[0029] like Figure 1~4 As shown, the magnetorheological mud damper of the present invention is composed of a cylinder shell 4 with a cylinder cover 2, a piston 10 with a double helical channel 11, and a pull rod 1; the spiral channel 11 of the piston 10 and the cylinder body Cavity 13 is filled with magnetorheological mud; the periphery of piston 10 fits closely with the inner wall of cylinder shell 4, and magnetorheological mud cannot flow from the gap between piston 10 and cylinder shell 4; The coil 6 generates a uniform magnetic field in the same direction as the piston 10; the two sides of the piston 10 are symmetrically provided with a pull rod 1 integrally fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com