Simple hydrogen single-stage pressurized purifying filling system and using method thereof

A filling system, hydrogen technology, applied in container filling method, container discharge method, hydrogen technology and other directions, can solve the problems of reducing hydrogen purity, existing pollution, noise, etc., achieving easy and convenient operation, less accessories, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

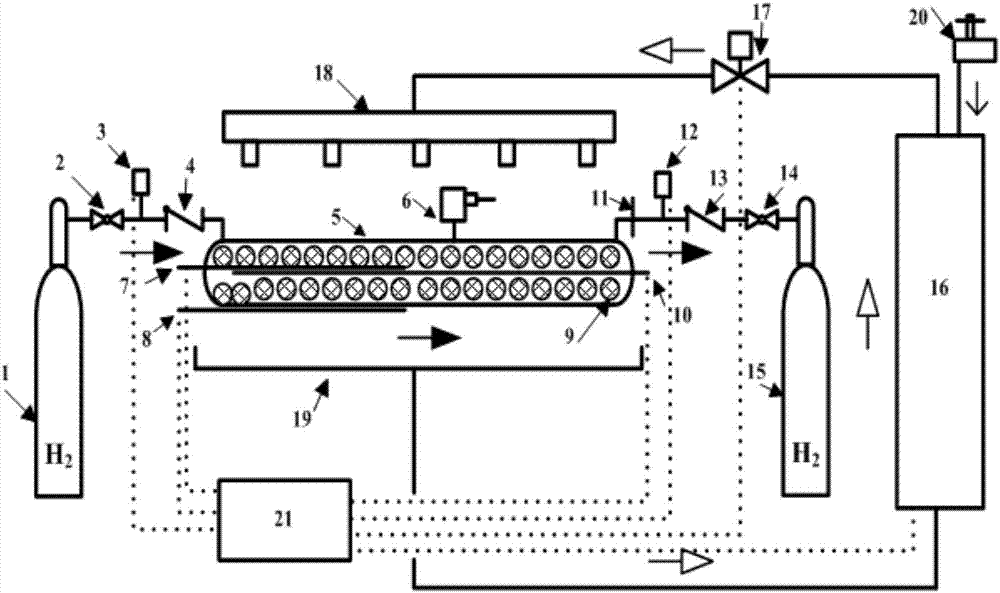

[0034] Such as figure 1 As shown, the low-pressure hydrogen cylinder 1 is directly connected to the inlet of the first ball valve 2 through the W21.8-14LHF thread and the ball nozzle. The outlet of the first ball valve 2 is respectively connected with the first pressure sensor 3 and the inlet of the first check valve 4 through a tee, and the outlet of the first check valve 4 is connected with the inlet of the high-pressure container 5 through a stainless steel pipe. A safety valve 6 is housed on the high-pressure container 5, and the outlet of the safety valve 6 leads to the outdoors by a plastic hose. When the internal pressure of the high-pressure container 5 is >15MPa, the safety valve 6 is automatically opened to complete pressure relief to avoid safety accidents caused by serious overpressure of the container due to misoperation or equipment failure. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com