Liquid metal battery heat insulation box with air cooling heat dissipation mechanism and heat dissipation method thereof

A liquid metal battery and heat dissipation mechanism technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of low space utilization, difficult heating, heating design with few partitions, etc., and achieve good temperature uniformity and stability , fast cooling speed, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

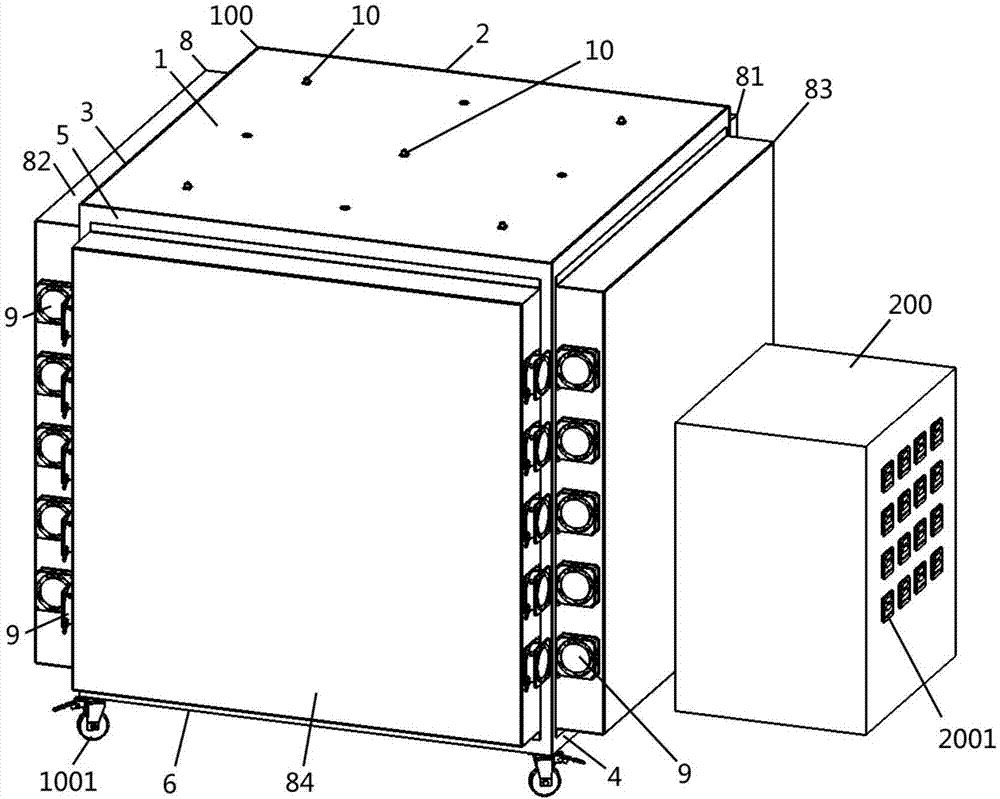

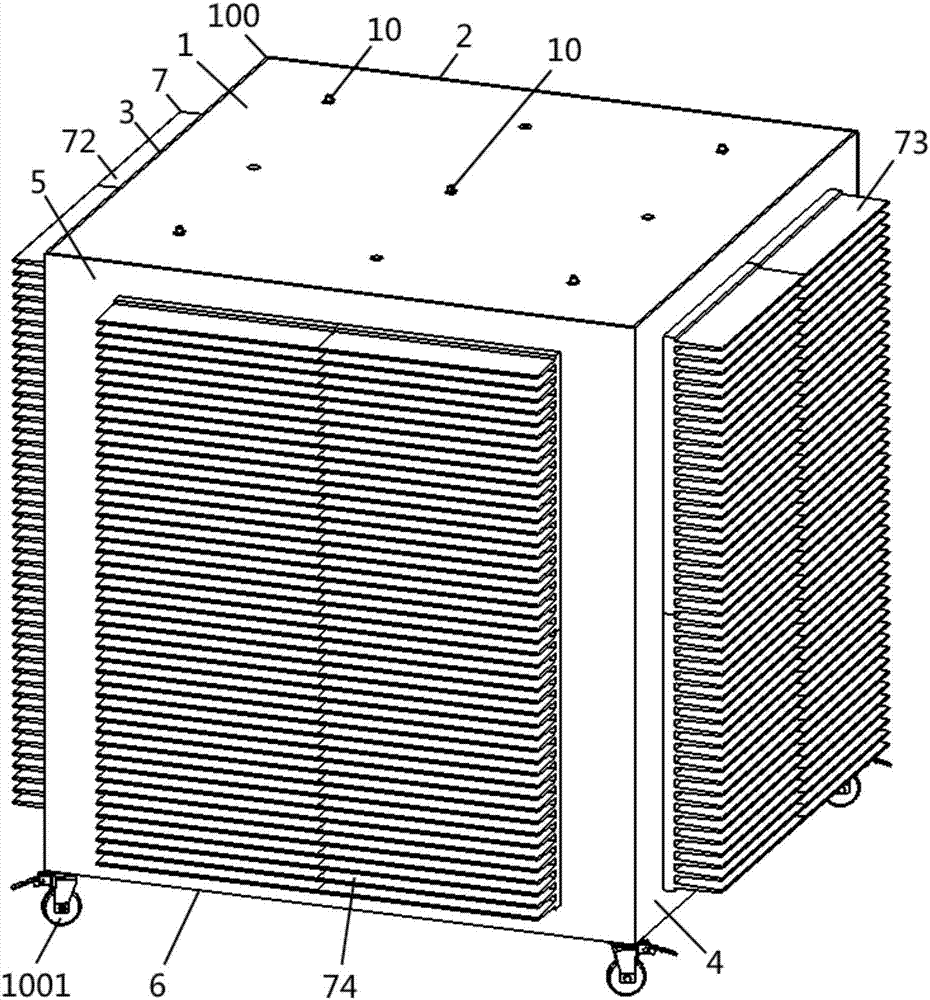

[0064] Embodiment 1: as Figure 1-11 , see figure 1 , a liquid metal battery incubator with air cooling and heat dissipation function of the present invention is composed of an incubator 100 and an electric control cabinet 200 . The specification of the insulation box 100 is a cuboid structure; the specification of the electric control cabinet 200 is a cuboid structure.

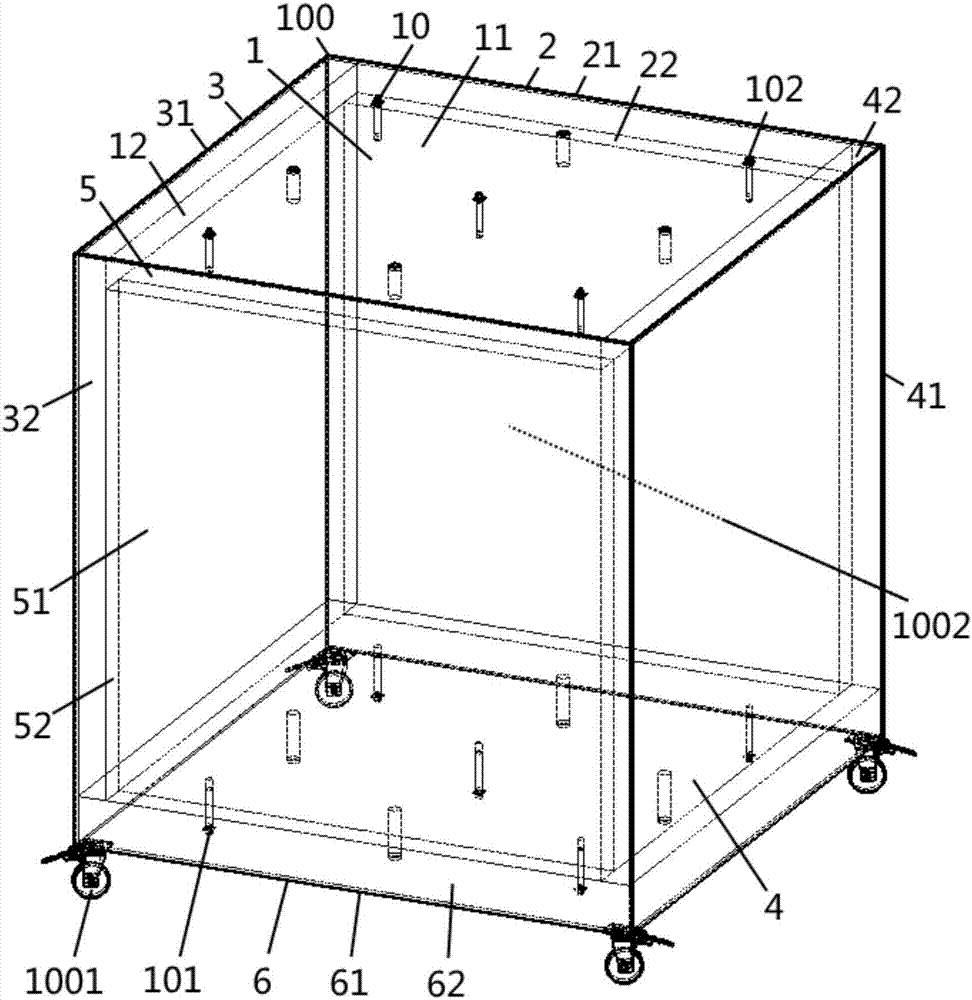

[0065] see Figure 1 to Figure 5 , the insulation box 100 of the present invention is surrounded by upper cover plate 1, rear side plate 2, left side plate 3, right side plate 4, front side plate 5 and bottom plate 6, and provides support and Turn to move. Wherein, the upper cover plate 1 includes the upper cover outer wall 11 and the upper cover insulation board 12 from the outside to the inside. The upper cover outer wall 11 is provided with a plurality of routing holes 111 and a plurality of thermocouple installation holes 112. The same upper cover insulation board 12 is also provided with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com