Low-vibration noise performance fractional slot concentrated winding permanent magnet motor and design method

A technology of concentrated winding and permanent magnet motor, which is applied in the shape/style/structure of winding conductors, static parts of magnetic circuit, shape/style/structure of magnetic circuit, etc., to reduce eddy current loss and reduce harmonics of magnetomotive force teeth , the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

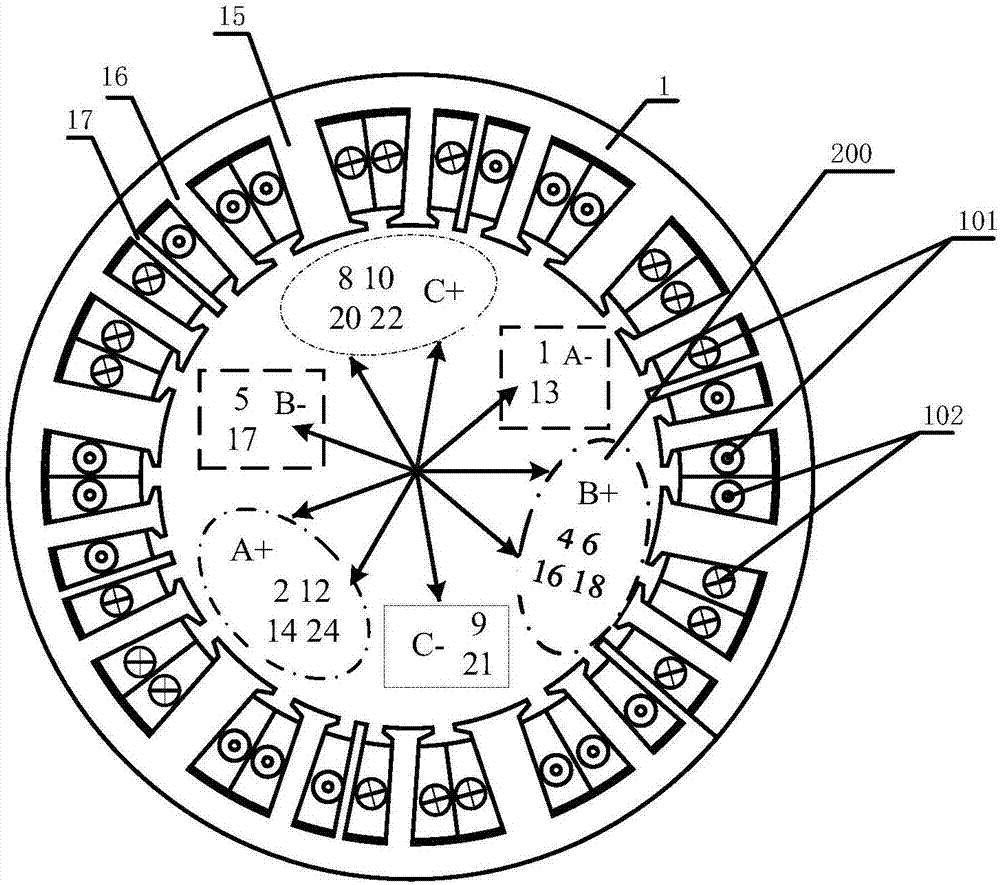

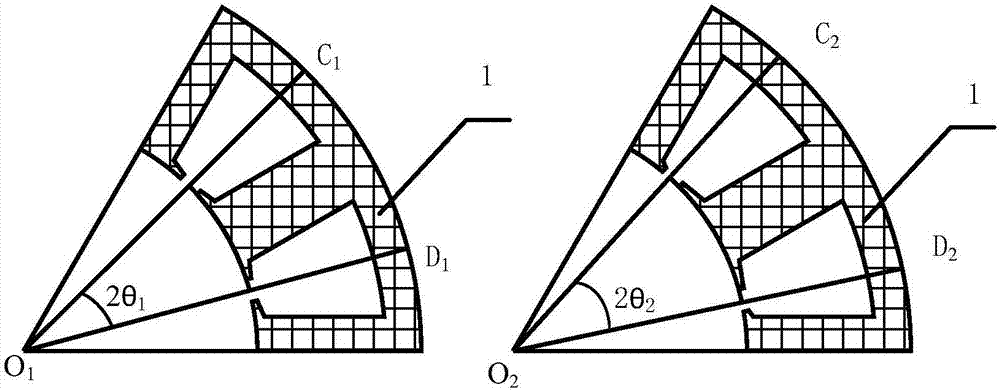

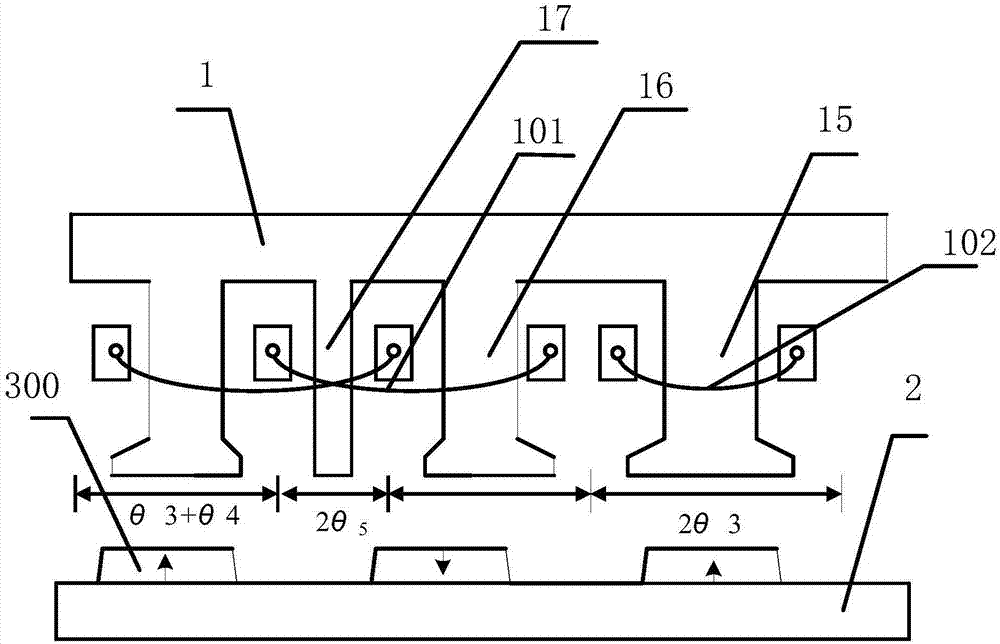

[0048] refer to figure 1 , the present invention is a method for reducing the vibration and noise characteristics of a fractional slot concentrated winding permanent magnet motor. The vibration and noise of the motor are affected by the tooth harmonics generated by the energized windings in the air gap. The higher the tooth harmonic content, the higher the vibration of the motor. and noisier. The present invention includes an outer stator 1, which contains three kinds of teeth, symmetrical teeth 15, asymmetrical teeth 16, and additional teeth 17. Motor slot potential star diagram 200, in general, a wave with a sinusoidal distribution in any space can be represented by a space vector, therefore, the magnetomotive force wave generated by each coil can be represented by a line segment, and the arrow represents the vector direction. The angle between each vector is equal to the spatial phase difference of the represented magnetomotive force harmonics, spaced apart by one wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com