Strawberry sandwich chocolate and preparation method thereof

A sandwich chocolate and chocolate technology, which is applied in the field of food processing, can solve the problems of poor chocolate taste and cumbersome production process, and achieve the effect of good taste and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

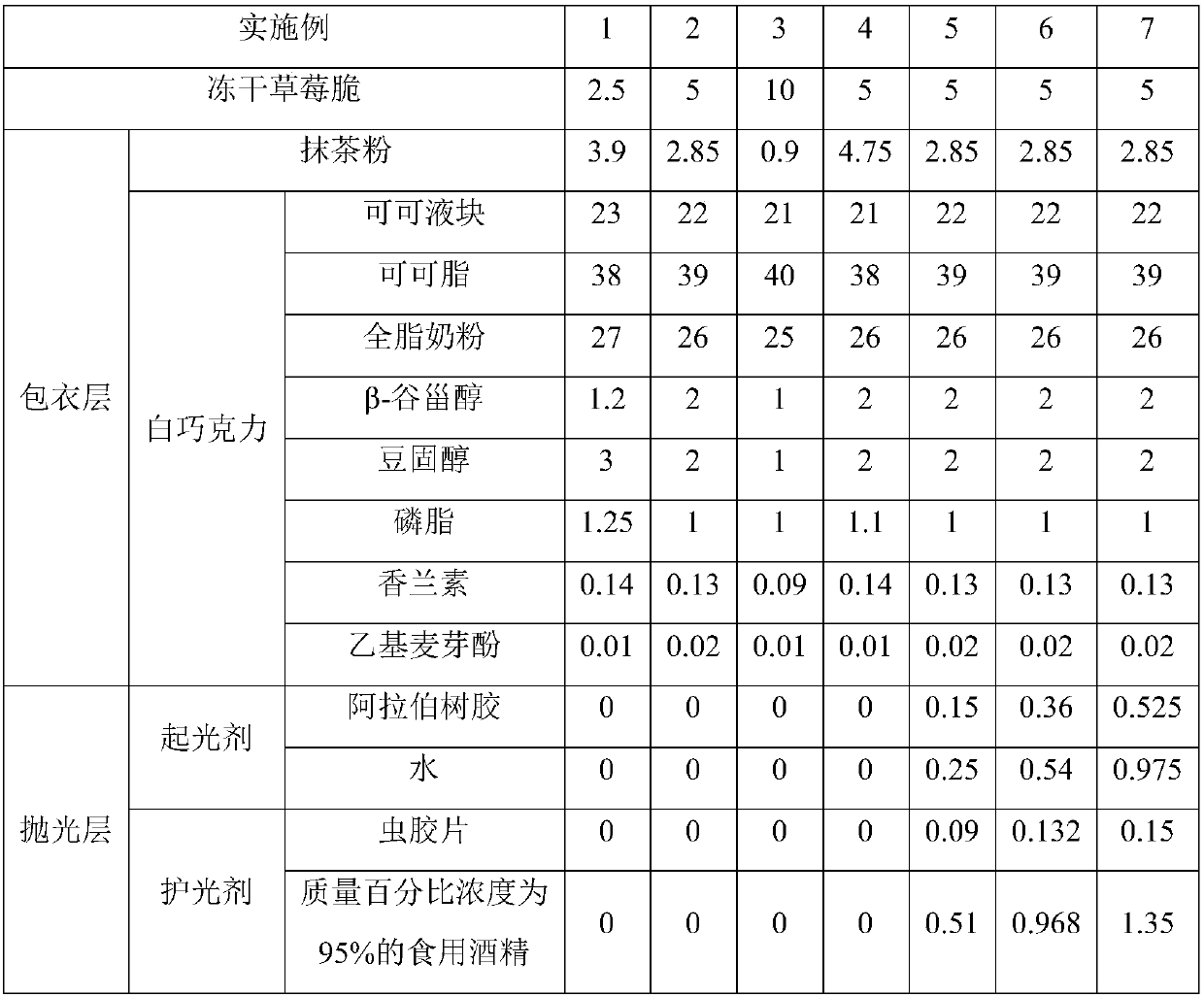

Embodiment 1

[0041] Embodiment 1: Strawberry filled chocolate is prepared by the following method:

[0042] (i) dissolving, filtering, and magnetically separating white chocolate and matcha powder at a temperature of 35°C;

[0043] (ii) Put in freeze-dried strawberry crisps, wrap them in chocolate, form a coating, and blow in cold air to cool until the chocolate slurry solidifies and the surface is dry;

[0044] (iii) After the coating is completed, let it stand for 4 hours under the temperature condition of 16° C. to obtain strawberry sandwich chocolate.

[0045]Among them, the freeze-dried strawberry crisp is prepared by the following method: fresh strawberries are pre-frozen, the pre-freezing temperature is -20°C, the cooling rate of the pre-freezing is 0.3°C / min, and the fresh strawberries are frozen under the temperature condition of -20°C Maintain for 0.5 hours; then heat the frozen strawberries and vacuumize at the same time, keep the temperature of the frozen strawberry layer not ...

Embodiment 2

[0046] Embodiment 2: Strawberry sandwich chocolate is prepared by the following method:

[0047] (i) dissolving, filtering, and magnetically separating white chocolate and matcha powder at a temperature of 36°C;

[0048] (ii) Put in freeze-dried strawberry crisps, wrap them in chocolate, form a coating, and blow in cold air to cool until the chocolate slurry solidifies and the surface is dry;

[0049] (iii) After the coating is completed, it is left to stand for 3.5 hours at a temperature of 17° C. to obtain strawberry filled chocolate.

[0050] Among them, the freeze-dried strawberry crisp is prepared by the following method: fresh strawberries are pre-frozen. 0.75 hours; after that, heat the frozen strawberries and vacuumize at the same time, keep the temperature of the frozen strawberry layer not exceeding -15°C and the temperature of the dried strawberry layer not exceeding 30°C under the condition of a vacuum of 12Pa, and maintain it for 4 hours ; Afterwards, the prelim...

Embodiment 3

[0051] Embodiment 3: Strawberry sandwich chocolate is prepared by the following method:

[0052] (i) dissolving, filtering, and magnetically separating white chocolate and matcha powder at a temperature of 37°C;

[0053] (ii) Put in freeze-dried strawberry crisps, wrap them in chocolate, form a coating, and blow in cold air to cool until the chocolate slurry solidifies and the surface is dry;

[0054] (iii) After the coating is completed, it is left to stand for 5 hours at a temperature of 18° C. to obtain strawberry sandwich chocolate.

[0055] Among them, the freeze-dried strawberry crisp is prepared by the following method: fresh strawberries are pre-frozen, the pre-freezing temperature is -25°C, the cooling rate of the pre-freezing is 0.5°C / min, and the temperature is maintained at -25°C 1 hour; after that, heat the frozen strawberries and vacuumize at the same time, keep the temperature of the frozen strawberry layer not exceeding -15°C and the temperature of the dried s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com