Production technology for abrasive paper of furniture

A production process and technology of sandpaper, applied in the direction of paper, papermaking, manufacturing tools, etc., can solve the problems of poor anti-clogging effect, poor water resistance, poor flexibility, etc., and achieve good water resistance, good anti-clogging effect, and eliminate the effect of poor flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

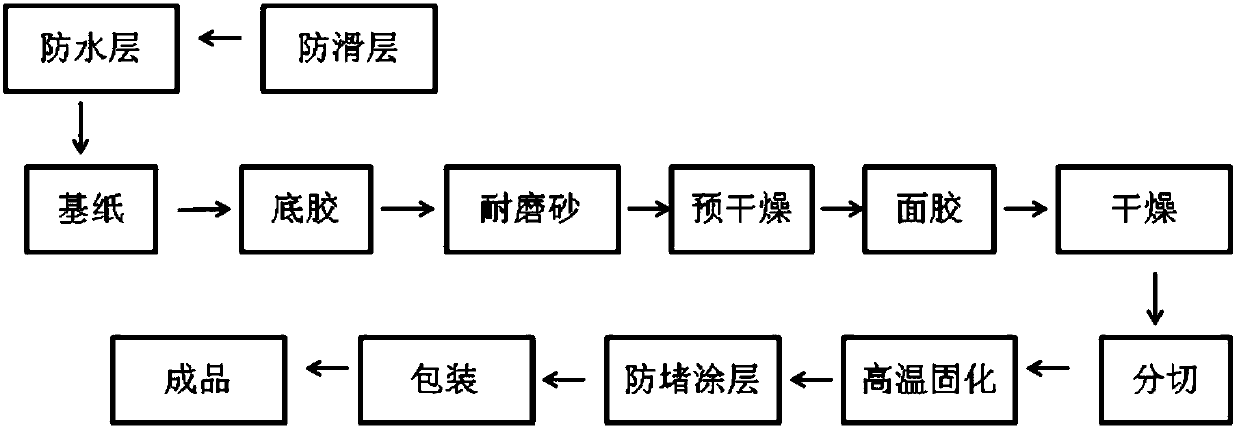

[0019] A production process of sandpaper for furniture, including base paper, waterproof coating, anti-skid layer, primer, wear-resistant sand, pre-drying, surface glue, drying, slitting, high-temperature curing, anti-blocking coating, packaging and finished products , it is characterized in that, described base paper adopts latex paper, and described latex paper is by adding chemical reagent in paper pulp, then makes through dipping and surface coating treatment; Described base paper one side is coated with waterproof coating, so The waterproof coating is coated with a non-slip coating; the other side of the base paper is coated with an adhesive primer to form a primer layer, and the primer layer is implanted with wear-resistant sand through an electrostatic sand planting process, and then pre-dried treatment; after the pre-drying treatment, it is necessary to coat the surface glue on the surface of the primer and wear-resistant sand, and then perform slitting after drying tre...

Embodiment 2

[0027] A production process of sandpaper for furniture, including base paper, waterproof coating, anti-skid layer, primer, wear-resistant sand, pre-drying, surface glue, drying, slitting, high-temperature curing, anti-blocking coating, packaging and finished products , it is characterized in that, described base paper adopts latex paper, and described latex paper is by adding chemical reagent in paper pulp, then makes through dipping and surface coating treatment; Described base paper one side is coated with waterproof coating, so The waterproof coating is coated with a non-slip coating; the other side of the base paper is coated with an adhesive primer to form a primer layer, and the primer layer is implanted with wear-resistant sand through an electrostatic sand planting process, and then pre-dried treatment; after the pre-drying treatment, it is necessary to coat the surface glue on the surface of the primer and wear-resistant sand, and then perform slitting after drying tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com