Fcdi device and application of enhanced trace ion capture based on ion exchange resin

A technology of ion exchange resin and ions, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of local current higher than the limit current, ion exchange membrane scaling, and low electrosorption efficiency, etc., to achieve good results Electrosorption adaptability, rapid capture ability, and the effect of solving the concentration polarization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

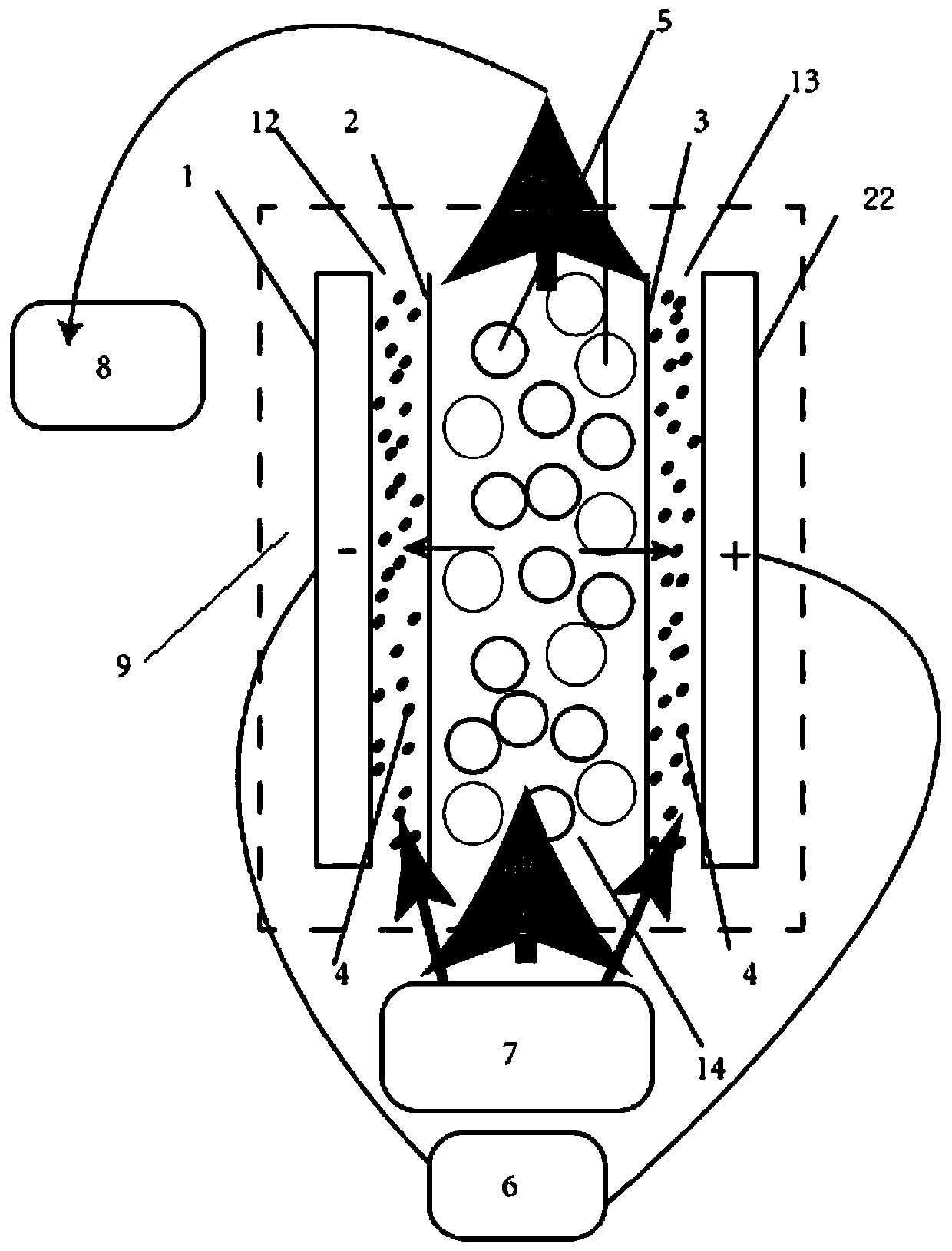

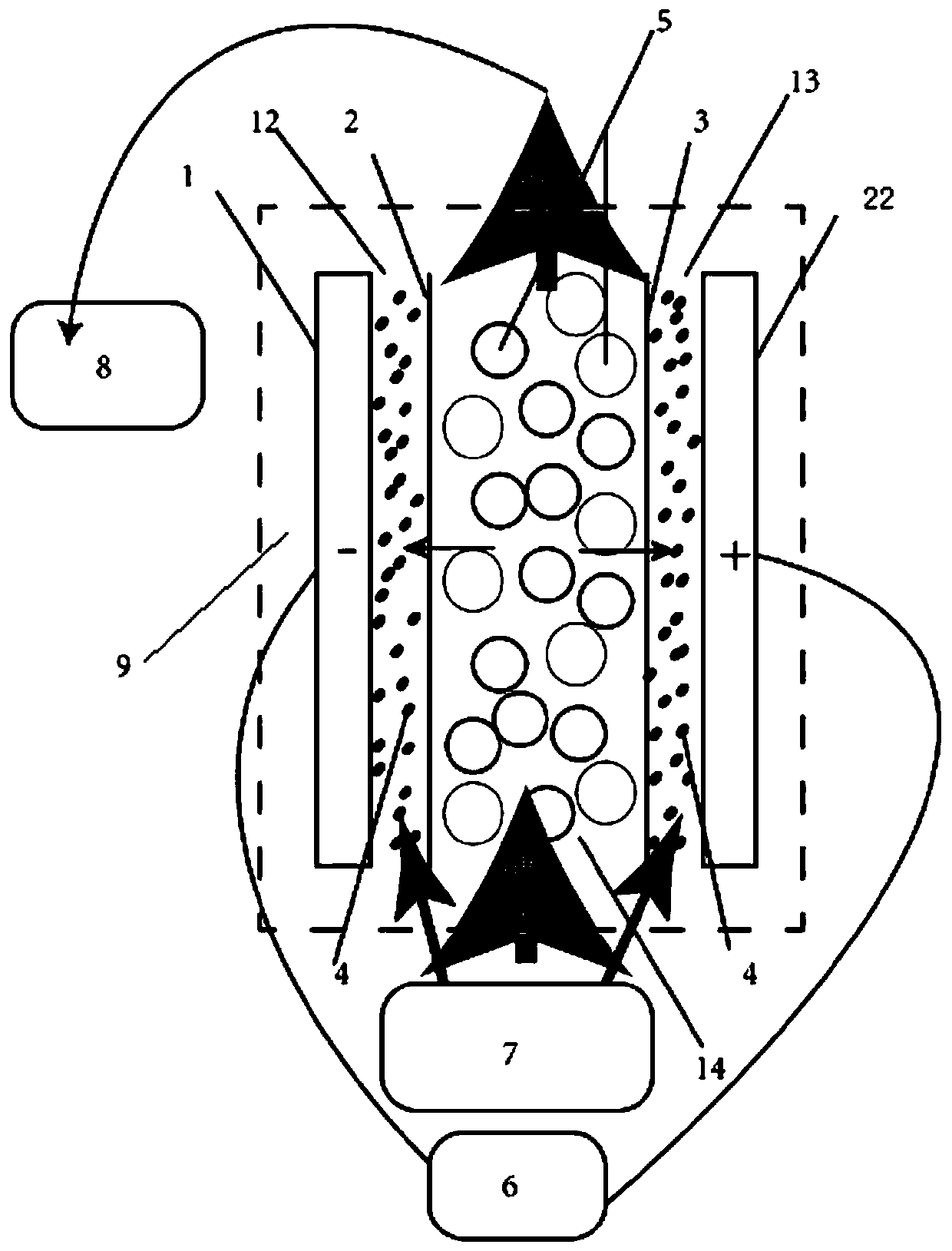

[0045] Anion-exchange membrane one 3, cation-exchange membrane one 2, anion-exchange membrane two 18, and cation-exchange membrane two 19 were soaked in 0.1mol / L potassium hydroxide solution and 0.1mol / L sulfuric acid solution for 24 hours before use, and after taking out Rinse several times with deionized water.

[0046] Before use, the ion exchange resin bed was soaked in 0.1mol / L potassium hydroxide solution and 0.1mol / L sulfuric acid solution for 24 hours, rinsed with deionized water several times after taking it out, and then dried in a vacuum oven at 60°C Dry.

[0047] Follow the steps below:

[0048] (1) Use deionized water (conductivity less than 5μs / cm) to prepare NaNO with initial concentrations of 5mg / L, 10mg / L and 15mg / L respectively 3 The solution simulates raw water.

[0049] (2) The fluid electrode 4 adopts the mode of circulating in and out, and the fluid electrode 4 is extracted from the beaker by using a dual-channel peristaltic pump, and enters from the b...

Embodiment 2

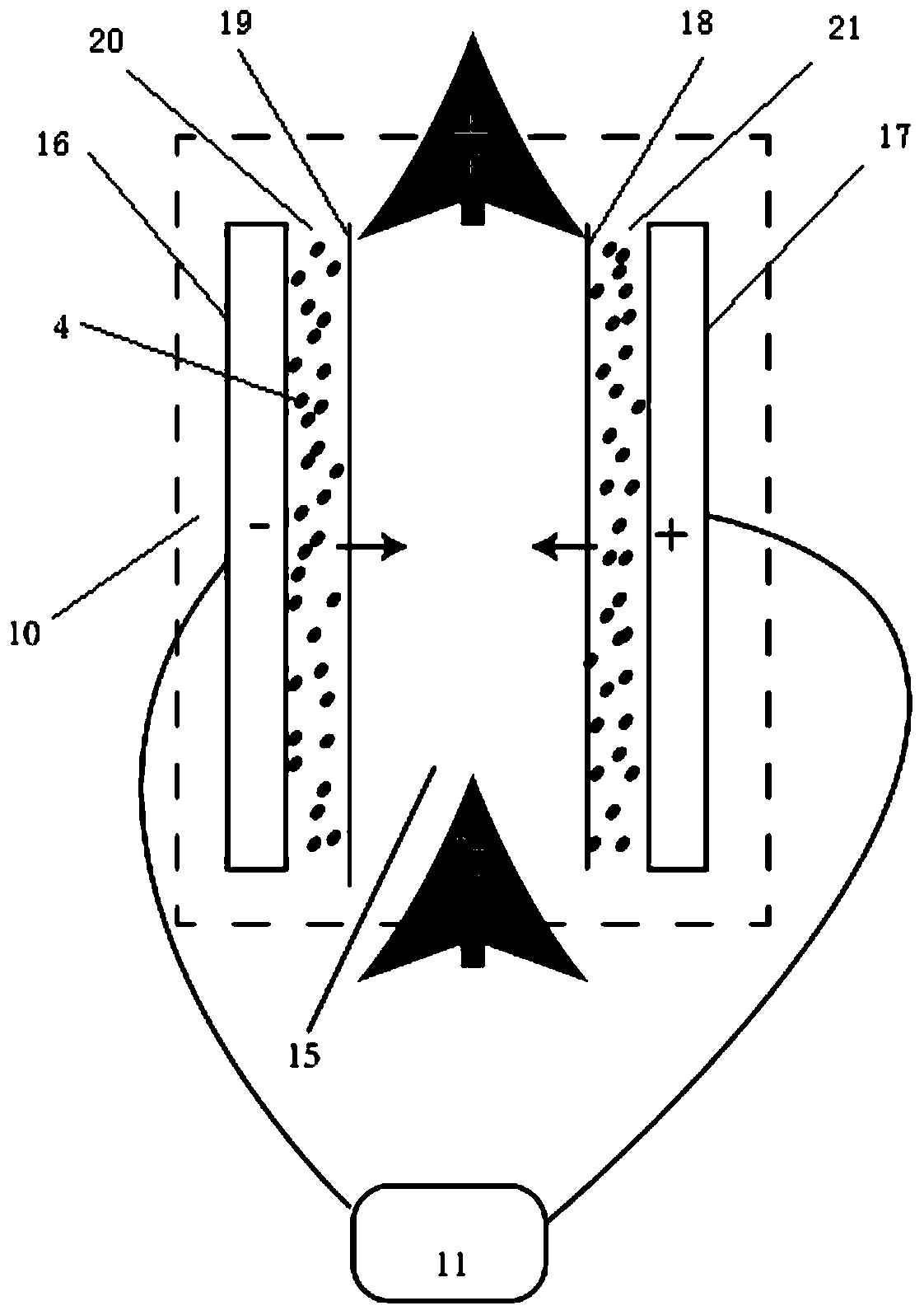

[0055] The difference from Example 1 is that deionized water (conductivity less than 5 μs / cm) is used to prepare NH with initial concentrations of 10 mg / L, 20 mg / L and 30 mg / L 4 Cl solution was used to simulate raw water; the removal rate of ammonium ions was calculated, and the results are shown in Table 1.

[0056] Table 1 Effect of ion exchange resin bed FCDI on low concentration NO 3 - and NH 4 + The removal rate

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com